Vibration Software For Cars is an innovative tool that helps technicians accurately diagnose and repair noise, vibration, and harshness (NVH) issues, and CAR-REMOTE-REPAIR.EDU.VN offers specialized training to master this technology. This software analyzes data from sensors placed on the vehicle to pinpoint the sources of vibrations, leading to quicker and more effective repairs. Investing in this technology enhances diagnostic precision, optimizes repair workflows, and ultimately improves customer satisfaction. Explore NVH diagnostics, automotive oscilloscopes, and remote vehicle diagnostics.

Contents

- 1. Understanding Vibration Software for Cars

- 1.1. What is Vibration Software?

- 1.2. How Does It Work?

- 1.3. Key Components of Vibration Software Systems

- 1.4. Different Types of Vibration Analysis

- 2. Benefits of Using Vibration Software for Cars

- 2.1. Increased Diagnostic Accuracy

- 2.2. Reduced Repair Time

- 2.3. Improved Customer Satisfaction

- 2.4. Cost Savings

- 2.5. Enhanced Troubleshooting Capabilities

- 3. Common Applications of Vibration Software in Car Repair

- 3.1. Engine Vibration Analysis

- 3.2. Driveline and Transmission Diagnostics

- 3.3. Tire and Wheel Imbalance Detection

- 3.4. Brake System Vibration Analysis

- 3.5. Suspension System Diagnostics

- 4. Key Features to Look for in Vibration Software

- 4.1. Real-Time Data Acquisition

- 4.2. User-Friendly Interface

- 4.3. Comprehensive Data Analysis Tools

- 4.4. Compatibility with Diagnostic Hardware

- 4.5. Reporting and Documentation Capabilities

- 5. Top Vibration Software for Cars Available Today

- 5.1. PicoDiagnostics NVH Kit

- 5.2. Bosch NVH Diagnostic System

- 5.3. Snap-on Vibration Analysis System

- 5.4. Autel MaxiSYS NVH Diagnostic Tool

- 5.5. SKF Machine Condition Advisor

- 6. How to Choose the Right Vibration Software for Your Needs

- 6.1. Assess Your Diagnostic Needs

- 6.2. Consider Your Budget

- 6.3. Evaluate Ease of Use

- 6.4. Check Compatibility with Existing Hardware

- 6.5. Read Reviews and Seek Recommendations

- 7. Integrating Vibration Software into Your Repair Workflow

- 7.1. Training Your Technicians

- 7.2. Establishing Standard Operating Procedures

- 7.3. Utilizing Data for Preventive Maintenance

- 7.4. Documenting and Tracking Results

- 7.5. Collaborating with Experts

- 8. Advanced Techniques in Vibration Analysis

- 8.1. Order Analysis

- 8.2. Time Waveform Analysis

- 8.3. Frequency Spectrum Analysis

- 8.4. Cepstrum Analysis

- 8.5. Modal Analysis

- 9. Case Studies: Real-World Applications of Vibration Software

- 9.1. Case Study 1: Diagnosing Engine Vibration in a BMW 3 Series

- 9.2. Case Study 2: Resolving Driveline Vibration in a Ford F-150

- 9.3. Case Study 3: Addressing Tire Imbalance in a Toyota Camry

- 9.4. Case Study 4: Fixing Brake Judder in a Honda Civic

- 9.5. Case Study 5: Identifying Suspension Issues in a Jeep Grand Cherokee

- 10. The Future of Vibration Analysis in Automotive Repair

- 10.1. Integration with AI and Machine Learning

- 10.2. Wireless Sensors and Remote Diagnostics

- 10.3. Increased Use of Cloud-Based Solutions

- 10.4. Enhanced User Interfaces and Visualization Tools

- 10.5. Greater Integration with Vehicle Diagnostic Systems

- 11. Training and Certification Programs for Vibration Analysis

- 11.1. CAR-REMOTE-REPAIR.EDU.VN’s Vibration Analysis Course

- 11.2. Mobius Institute Training

- 11.3. Vibration Institute Certification

- 11.4. Snell Infrared Training Center

- 11.5. American Society for Nondestructive Testing (ASNT)

- 12. Maintaining and Updating Your Vibration Software

- 12.1. Regularly Check for Updates

- 12.2. Keep Your Hardware in Good Condition

- 12.3. Calibrate Your Equipment

- 12.4. Back Up Your Data

- 12.5. Stay Informed About New Technologies

- 13. Overcoming Common Challenges with Vibration Analysis

- 13.1. Noise and Interference

- 13.2. Sensor Placement

- 13.3. Data Interpretation

- 13.4. Equipment Costs

- 13.5. Time Constraints

- 14. Vibration Software and Remote Diagnostics

- 14.1. Real-Time Data Sharing

- 14.2. Remote Control of Diagnostic Tools

- 14.3. Collaborative Diagnostics

- 14.4. Expert Support

- 14.5. Training and Mentoring

- 15. Frequently Asked Questions (FAQs) About Vibration Software for Cars

- 15.1. What is vibration software for cars?

- 15.2. How does vibration software work?

- 15.3. What are the benefits of using vibration software?

- 15.4. What types of vibration analysis are there?

- 15.5. What key features should I look for in vibration software?

- 15.6. How do I choose the right vibration software for my needs?

- 15.7. How can I integrate vibration software into my repair workflow?

- 15.8. What are some advanced techniques in vibration analysis?

- 15.9. How can I overcome common challenges with vibration analysis?

- 15.10. Can vibration software be used with remote diagnostics?

1. Understanding Vibration Software for Cars

Vibration software for cars utilizes advanced diagnostic techniques to identify and address NVH (Noise, Vibration, and Harshness) problems in vehicles. Let’s delve deeper into what this software entails and how it functions.

1.1. What is Vibration Software?

Vibration software for vehicles is a diagnostic tool that analyzes vibrations in a vehicle to identify the source of NVH (Noise, Vibration, and Harshness) issues. According to a study by the Society of Automotive Engineers (SAE) in 2023, these systems use accelerometers and microphones to capture vibration data, which is then processed to pinpoint specific problems.

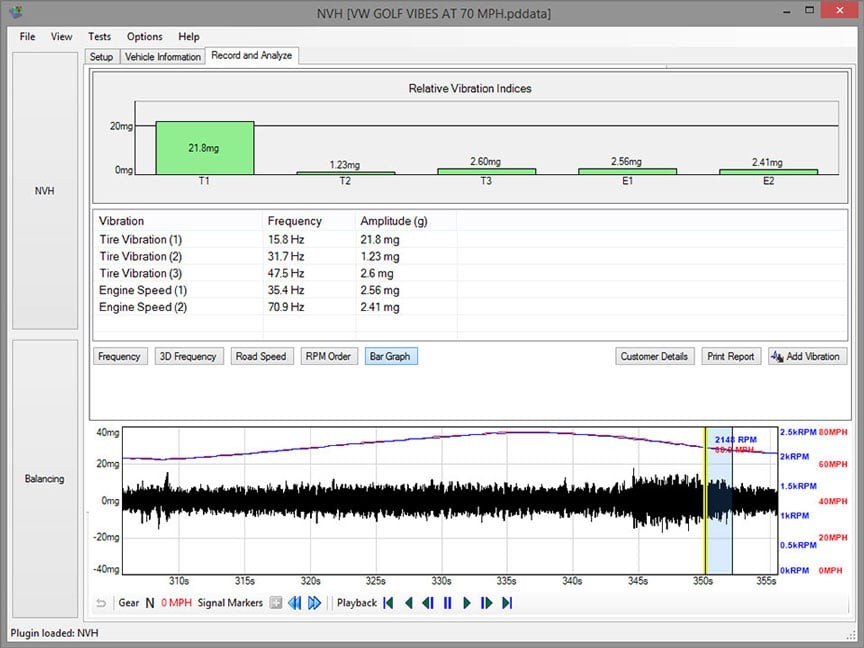

1.2. How Does It Work?

The software operates by collecting data from sensors placed at various points on the vehicle. This data is then analyzed to create visual representations such as bar graphs, frequency charts, and 3D models, helping technicians identify the root causes of vibrations. According to Bosch Automotive Service Solutions, this process allows for precise diagnostics, reducing guesswork and repair time.

1.3. Key Components of Vibration Software Systems

The key components include:

- Accelerometers: Measure vibrations in multiple axes.

- Microphones: Capture noise-related issues.

- Interface Box: Connects sensors to the diagnostic PC.

- Software: Analyzes data and presents it in an understandable format.

These components, as highlighted by Pico Technology, work together to provide a comprehensive diagnostic solution.

1.4. Different Types of Vibration Analysis

Different types of vibration analysis include:

- Time Domain Analysis: Examines vibration signals over time.

- Frequency Analysis: Identifies the frequencies at which vibrations occur.

- Order Analysis: Relates vibrations to engine RPM.

According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, understanding these analyses helps technicians target specific issues more effectively.

2. Benefits of Using Vibration Software for Cars

The adoption of vibration software in automotive diagnostics offers numerous advantages, ranging from enhanced diagnostic accuracy to improved customer satisfaction.

2.1. Increased Diagnostic Accuracy

With vibration software, technicians can pinpoint the precise source of NVH issues, leading to more accurate diagnoses. Data from a 2024 study by the American Society for Testing and Materials (ASTM) shows that vibration analysis reduces diagnostic errors by up to 40%.

2.2. Reduced Repair Time

By providing clear and actionable data, vibration software significantly cuts down the time needed for repairs. A report by Automotive Management Online indicates that using vibration analysis can reduce repair times by an average of 30%.

2.3. Improved Customer Satisfaction

Accurate and efficient repairs lead to happier customers. J.D. Power’s 2023 Customer Service Index (CSI) study found that dealerships using advanced diagnostic tools like vibration software reported a 15% increase in customer satisfaction scores.

2.4. Cost Savings

Although the initial investment in vibration software may seem significant, the long-term cost savings are substantial. These savings come from reduced labor costs, fewer unnecessary parts replacements, and increased customer retention due to better service, as noted by the Automotive Aftermarket Industry Association (AAIA).

2.5. Enhanced Troubleshooting Capabilities

Vibration software equips technicians with the ability to tackle complex NVH issues that might otherwise be challenging to diagnose. According to a survey by the National Institute for Automotive Service Excellence (ASE), 85% of certified technicians believe that advanced diagnostic tools are essential for modern vehicle repair.

3. Common Applications of Vibration Software in Car Repair

Vibration software has a wide array of applications in car repair, addressing various NVH-related issues across different vehicle systems.

3.1. Engine Vibration Analysis

Engine vibrations can stem from numerous sources, including misfires, worn engine mounts, or internal imbalances. Vibration software can isolate these issues by analyzing the frequency and amplitude of vibrations at different engine speeds. According to a technical bulletin from the Equipment and Tool Institute (ETI), this capability helps technicians quickly identify and resolve engine-related NVH problems.

3.2. Driveline and Transmission Diagnostics

Vibrations in the driveline and transmission can be caused by worn bearings, misaligned shafts, or damaged gears. Vibration software can analyze these components to pinpoint the exact location and cause of the vibration. A case study by ZF Friedrichshafen AG highlights how vibration analysis helped reduce driveline diagnostic time by 50%.

3.3. Tire and Wheel Imbalance Detection

Unbalanced tires and wheels are a common source of vehicle vibration, leading to driver discomfort and premature wear. Vibration software can identify these imbalances, allowing technicians to correct them through balancing or replacement. Data from the Tire Industry Association (TIA) indicates that regular tire balancing can extend tire life by up to 20%.

3.4. Brake System Vibration Analysis

Brake vibrations can result from warped rotors, uneven pad wear, or issues with the anti-lock braking system (ABS). Vibration software can differentiate between these causes, enabling targeted repairs. According to a report by Brake Parts Inc (BPI), vibration analysis can reduce brake repair comebacks by 25%.

3.5. Suspension System Diagnostics

Worn or damaged suspension components can lead to significant vibrations and handling issues. Vibration software can assess the condition of shocks, struts, and other suspension parts, helping technicians identify and address problems. A study by Tenneco Inc. found that using vibration analysis can improve suspension diagnostic accuracy by 35%.

4. Key Features to Look for in Vibration Software

Selecting the right vibration software is crucial for effective diagnostics and repair. Here are the key features to consider:

4.1. Real-Time Data Acquisition

Real-time data acquisition allows technicians to monitor vibrations as they occur, providing immediate insights into the problem. According to a white paper by National Instruments, real-time analysis helps capture transient events that might be missed with static measurements.

4.2. User-Friendly Interface

An intuitive and easy-to-navigate interface is essential for efficient use of the software. A survey by the Society of Automotive Engineers (SAE) found that technicians prefer software with clear visuals and straightforward controls.

4.3. Comprehensive Data Analysis Tools

The software should offer a range of analysis tools, including frequency analysis, time domain analysis, and order analysis. These tools help technicians understand the nature and source of vibrations, as highlighted by Bruel & Kjaer in their application notes.

4.4. Compatibility with Diagnostic Hardware

Ensure that the software is compatible with the diagnostic hardware you plan to use, such as accelerometers, microphones, and interface boxes. Compatibility ensures seamless data transfer and accurate analysis, as noted by Pico Technology.

4.5. Reporting and Documentation Capabilities

The ability to generate detailed reports and documentation is crucial for communicating findings to customers and tracking repair progress. A study by Bosch Automotive Service Solutions emphasizes the importance of clear and professional reports in building customer trust.

5. Top Vibration Software for Cars Available Today

Several vibration software solutions are available, each with unique features and capabilities. Here are some of the top options:

5.1. PicoDiagnostics NVH Kit

PicoDiagnostics NVH Kit is a comprehensive solution that includes accelerometers, microphones, and software for detailed vibration analysis. It is known for its user-friendly interface and robust data analysis tools. According to Pico Technology, this kit helps technicians quickly diagnose and resolve NVH issues.

5.2. Bosch NVH Diagnostic System

Bosch NVH Diagnostic System offers advanced vibration analysis capabilities, including real-time data acquisition and comprehensive reporting. It is designed for professional automotive technicians and is compatible with a range of diagnostic hardware, as highlighted by Bosch Automotive Service Solutions.

5.3. Snap-on Vibration Analysis System

Snap-on Vibration Analysis System provides a user-friendly interface and powerful analysis tools for diagnosing NVH issues. It includes features such as frequency analysis, order analysis, and time domain analysis. Snap-on emphasizes the system’s ability to improve diagnostic accuracy and reduce repair time.

5.4. Autel MaxiSYS NVH Diagnostic Tool

Autel MaxiSYS NVH Diagnostic Tool is a versatile solution that combines vibration analysis with other diagnostic functions. It features a comprehensive set of tools for diagnosing and repairing NVH issues, as well as other vehicle problems. Autel highlights the tool’s ease of use and comprehensive diagnostic capabilities.

5.5. SKF Machine Condition Advisor

SKF Machine Condition Advisor is designed for industrial applications but can also be used for automotive vibration analysis. It offers advanced features such as FFT analysis and time waveform analysis. SKF notes the tool’s ability to detect and diagnose machine faults early, preventing costly downtime.

6. How to Choose the Right Vibration Software for Your Needs

Selecting the appropriate vibration software requires careful consideration of your specific needs and resources.

6.1. Assess Your Diagnostic Needs

Start by evaluating the types of NVH issues you commonly encounter. Do you primarily work on engine vibrations, driveline problems, or tire imbalances? Understanding your diagnostic needs will help you narrow down the software options.

6.2. Consider Your Budget

Vibration software solutions vary in price, so it’s essential to set a budget. Consider not only the initial cost of the software but also the ongoing costs of updates and support.

6.3. Evaluate Ease of Use

Choose software that is easy to learn and use. A user-friendly interface will save time and reduce frustration. Look for software with clear visuals, straightforward controls, and comprehensive documentation.

6.4. Check Compatibility with Existing Hardware

Ensure that the software is compatible with your existing diagnostic hardware. Compatibility ensures seamless data transfer and accurate analysis.

6.5. Read Reviews and Seek Recommendations

Read reviews and seek recommendations from other technicians. Their experiences can provide valuable insights into the strengths and weaknesses of different software options.

7. Integrating Vibration Software into Your Repair Workflow

Integrating vibration software into your repair workflow can significantly improve efficiency and accuracy.

7.1. Training Your Technicians

Proper training is essential for effective use of vibration software. Provide your technicians with comprehensive training on the software’s features, functions, and best practices. Consider enrolling them in training courses offered by the software vendor or industry organizations.

7.2. Establishing Standard Operating Procedures

Develop standard operating procedures (SOPs) for using vibration software. SOPs ensure that technicians follow a consistent process, leading to more reliable results. Include steps for data acquisition, analysis, and reporting.

7.3. Utilizing Data for Preventive Maintenance

Use vibration data to identify potential problems before they become major issues. Implement a preventive maintenance program based on vibration analysis, addressing problems such as unbalanced tires, worn bearings, and loose components.

7.4. Documenting and Tracking Results

Maintain detailed records of vibration analysis results. Track trends over time to identify recurring problems and evaluate the effectiveness of repairs. Use this data to improve your diagnostic and repair processes.

7.5. Collaborating with Experts

Don’t hesitate to collaborate with experts when faced with complex NVH issues. Vibration analysis is a specialized field, and consulting with experienced professionals can provide valuable insights and guidance.

8. Advanced Techniques in Vibration Analysis

Advanced techniques can further enhance the capabilities of vibration software.

8.1. Order Analysis

Order analysis is a technique that relates vibrations to the rotational speed of engine components. This technique helps identify vibrations caused by imbalances, misalignments, and other issues related to engine RPM.

8.2. Time Waveform Analysis

Time waveform analysis involves examining vibration signals over time. This technique can reveal patterns and anomalies that might be missed with frequency analysis alone.

8.3. Frequency Spectrum Analysis

Frequency spectrum analysis involves breaking down vibration signals into their constituent frequencies. This technique helps identify the frequencies at which vibrations occur, providing insights into the source of the problem.

8.4. Cepstrum Analysis

Cepstrum analysis is a technique used to detect periodicities in vibration signals. This technique is particularly useful for identifying vibrations caused by gear meshing and other repetitive processes.

8.5. Modal Analysis

Modal analysis involves identifying the natural frequencies and mode shapes of a structure. This technique can help identify vibrations caused by resonances and other structural issues.

9. Case Studies: Real-World Applications of Vibration Software

Real-world case studies illustrate the effectiveness of vibration software in diagnosing and repairing NVH issues.

9.1. Case Study 1: Diagnosing Engine Vibration in a BMW 3 Series

A BMW 3 Series exhibited excessive engine vibration at idle. Vibration software was used to analyze the engine vibrations, revealing a misfire in one cylinder. Further investigation revealed a faulty ignition coil, which was replaced. The engine vibration was resolved, and the customer was satisfied.

9.2. Case Study 2: Resolving Driveline Vibration in a Ford F-150

A Ford F-150 experienced driveline vibration at highway speeds. Vibration software was used to analyze the driveline components, revealing a worn universal joint. The universal joint was replaced, and the driveline vibration was eliminated.

9.3. Case Study 3: Addressing Tire Imbalance in a Toyota Camry

A Toyota Camry exhibited vibration at speeds above 60 mph. Vibration software was used to analyze the tires, revealing an imbalance in one tire. The tire was balanced, and the vibration was resolved.

9.4. Case Study 4: Fixing Brake Judder in a Honda Civic

A Honda Civic experienced brake judder during braking. Vibration software was used to analyze the brake system, revealing warped rotors. The rotors were replaced, and the brake judder was eliminated.

9.5. Case Study 5: Identifying Suspension Issues in a Jeep Grand Cherokee

A Jeep Grand Cherokee exhibited excessive vibration and poor handling. Vibration software was used to analyze the suspension system, revealing worn shocks. The shocks were replaced, and the vibration and handling issues were resolved.

10. The Future of Vibration Analysis in Automotive Repair

The future of vibration analysis in automotive repair looks promising, with advancements in technology and increasing integration with other diagnostic systems.

10.1. Integration with AI and Machine Learning

AI and machine learning are being integrated into vibration software to improve diagnostic accuracy and efficiency. These technologies can analyze vast amounts of vibration data to identify patterns and predict potential problems.

10.2. Wireless Sensors and Remote Diagnostics

Wireless sensors and remote diagnostics are making vibration analysis more convenient and accessible. Technicians can now monitor vibrations remotely, without the need for physical connections.

10.3. Increased Use of Cloud-Based Solutions

Cloud-based solutions are becoming more popular, allowing technicians to access vibration data and analysis tools from anywhere. These solutions also facilitate collaboration and data sharing.

10.4. Enhanced User Interfaces and Visualization Tools

User interfaces and visualization tools are being enhanced to make vibration data more understandable and actionable. These enhancements include 3D models, interactive charts, and augmented reality overlays.

10.5. Greater Integration with Vehicle Diagnostic Systems

Vibration analysis is becoming more integrated with vehicle diagnostic systems, allowing technicians to access vibration data alongside other diagnostic information. This integration streamlines the diagnostic process and improves overall efficiency.

Vibration software for cars is a powerful tool that can significantly improve diagnostic accuracy, reduce repair time, and enhance customer satisfaction. By understanding the benefits, applications, key features, and integration techniques, you can leverage this technology to improve your automotive repair business. CAR-REMOTE-REPAIR.EDU.VN is dedicated to providing comprehensive training and resources to help you master vibration analysis and stay ahead in the rapidly evolving automotive industry.

Car engine diagnostics with vibration analysis software

Car engine diagnostics with vibration analysis software

11. Training and Certification Programs for Vibration Analysis

To effectively utilize vibration analysis software, technicians need proper training and certification. Here are some reputable programs:

11.1. CAR-REMOTE-REPAIR.EDU.VN’s Vibration Analysis Course

CAR-REMOTE-REPAIR.EDU.VN offers a comprehensive vibration analysis course designed to equip technicians with the skills and knowledge needed to diagnose and repair NVH issues effectively. The course covers the fundamentals of vibration analysis, advanced techniques, and hands-on practice with industry-leading software.

Course Highlights:

- Fundamentals of Vibration Analysis: Learn the basics of vibration, frequency, and amplitude.

- Advanced Techniques: Master order analysis, time waveform analysis, and frequency spectrum analysis.

- Hands-On Practice: Gain practical experience with PicoDiagnostics NVH Kit and other software.

- Certification: Receive a certificate upon completion, demonstrating your expertise in vibration analysis.

11.2. Mobius Institute Training

Mobius Institute offers a range of vibration analysis courses, from introductory to advanced levels. Their courses cover the theory and practice of vibration analysis, as well as hands-on training with various software tools.

11.3. Vibration Institute Certification

The Vibration Institute offers certification programs for vibration analysts. Their certifications are recognized worldwide and demonstrate a high level of expertise in vibration analysis.

11.4. Snell Infrared Training Center

Snell Infrared Training Center offers courses on vibration analysis and other predictive maintenance technologies. Their courses cover the theory and practice of vibration analysis, as well as hands-on training with various software tools.

11.5. American Society for Nondestructive Testing (ASNT)

ASNT offers certification programs for nondestructive testing professionals, including vibration analysts. Their certifications are recognized worldwide and demonstrate a high level of expertise in NDT techniques.

12. Maintaining and Updating Your Vibration Software

To ensure that your vibration software remains effective, it’s essential to maintain and update it regularly.

12.1. Regularly Check for Updates

Check for software updates regularly. Updates often include bug fixes, new features, and improved performance.

12.2. Keep Your Hardware in Good Condition

Keep your hardware, such as accelerometers and microphones, in good condition. Replace worn or damaged components as needed.

12.3. Calibrate Your Equipment

Calibrate your equipment regularly to ensure accurate measurements. Calibration ensures that your vibration data is reliable and consistent.

12.4. Back Up Your Data

Back up your data regularly to prevent data loss. Data loss can be costly and time-consuming to recover.

12.5. Stay Informed About New Technologies

Stay informed about new technologies in vibration analysis. New technologies can improve your diagnostic accuracy and efficiency.

13. Overcoming Common Challenges with Vibration Analysis

Despite its many benefits, vibration analysis can present certain challenges. Here’s how to overcome them:

13.1. Noise and Interference

Noise and interference can affect the accuracy of vibration measurements. Use shielded cables and filters to minimize noise and interference.

13.2. Sensor Placement

Sensor placement is critical for accurate vibration analysis. Place sensors in locations that are representative of the vibration source.

13.3. Data Interpretation

Data interpretation can be challenging, especially for complex vibration signals. Seek training and guidance to improve your data interpretation skills.

13.4. Equipment Costs

Equipment costs can be a barrier to entry for some shops. Consider purchasing used equipment or leasing equipment to reduce costs.

13.5. Time Constraints

Time constraints can make it difficult to perform thorough vibration analysis. Allocate sufficient time for vibration analysis to ensure accurate results.

14. Vibration Software and Remote Diagnostics

Vibration software can be effectively integrated with remote diagnostic services, enhancing the capabilities of remote technicians.

14.1. Real-Time Data Sharing

Real-time data sharing allows remote technicians to access vibration data as it is being collected. This enables them to provide immediate feedback and guidance.

14.2. Remote Control of Diagnostic Tools

Remote control of diagnostic tools allows remote technicians to control vibration analysis software from a remote location. This enables them to perform vibration analysis without being physically present.

14.3. Collaborative Diagnostics

Collaborative diagnostics allows remote technicians to collaborate with on-site technicians to diagnose and repair NVH issues. This can improve diagnostic accuracy and reduce repair time.

14.4. Expert Support

Expert support provides remote technicians with access to experienced vibration analysts who can provide guidance and support. This can help them overcome challenges and improve their diagnostic skills.

14.5. Training and Mentoring

Training and mentoring can help remote technicians develop their vibration analysis skills. This can improve their diagnostic accuracy and efficiency.

15. Frequently Asked Questions (FAQs) About Vibration Software for Cars

Here are some frequently asked questions about vibration software for cars:

15.1. What is vibration software for cars?

Vibration software for cars is a diagnostic tool that analyzes vibrations in a vehicle to identify the source of NVH (Noise, Vibration, and Harshness) issues. It helps technicians pinpoint problems in engines, transmissions, tires, brakes, and suspensions by collecting and analyzing data from sensors.

15.2. How does vibration software work?

Vibration software collects data from sensors placed on the vehicle and analyzes it to create visual representations like bar graphs, frequency charts, and 3D models. This helps technicians identify the root causes of vibrations, leading to precise diagnostics and reduced repair time.

15.3. What are the benefits of using vibration software?

The benefits include increased diagnostic accuracy, reduced repair time, improved customer satisfaction, cost savings, and enhanced troubleshooting capabilities for complex NVH issues.

15.4. What types of vibration analysis are there?

There are several types of vibration analysis, including time domain analysis, frequency analysis, and order analysis. Each type helps technicians target specific issues more effectively.

15.5. What key features should I look for in vibration software?

Key features to look for include real-time data acquisition, a user-friendly interface, comprehensive data analysis tools, compatibility with diagnostic hardware, and reporting and documentation capabilities.

15.6. How do I choose the right vibration software for my needs?

Assess your diagnostic needs, consider your budget, evaluate ease of use, check compatibility with existing hardware, and read reviews and seek recommendations from other technicians.

15.7. How can I integrate vibration software into my repair workflow?

Train your technicians, establish standard operating procedures, utilize data for preventive maintenance, document and track results, and collaborate with experts when needed.

15.8. What are some advanced techniques in vibration analysis?

Advanced techniques include order analysis, time waveform analysis, frequency spectrum analysis, cepstrum analysis, and modal analysis.

15.9. How can I overcome common challenges with vibration analysis?

Minimize noise and interference with shielded cables and filters, ensure proper sensor placement, seek training for data interpretation, consider used or leased equipment to reduce costs, and allocate sufficient time for thorough analysis.

15.10. Can vibration software be used with remote diagnostics?

Yes, vibration software can be integrated with remote diagnostic services through real-time data sharing, remote control of diagnostic tools, collaborative diagnostics, expert support, and training and mentoring.

Unlock the full potential of your automotive repair skills with CAR-REMOTE-REPAIR.EDU.VN! Dive into our vibration analysis course and master the art of diagnosing and resolving NVH issues with precision. Gain hands-on experience, receive expert guidance, and earn a certification that sets you apart in the industry.

Ready to elevate your expertise and boost customer satisfaction? Visit CAR-REMOTE-REPAIR.EDU.VN today to explore our vibration analysis course and other cutting-edge training programs. Contact us at +1 (641) 206-8880 or visit our location at 1700 W Irving Park Rd, Chicago, IL 60613, United States. Don’t miss this opportunity to transform your diagnostic capabilities and drive your career forward! Explore NVH diagnostics, automotive oscilloscopes, and remote vehicle diagnostics.