Are you eager to elevate your auto repair skills and explore the world of remote repair services? The Software Used In Car Design Industry encompasses a range of sophisticated tools essential for modern automotive engineering and design, from CAD (Computer-Aided Design) to CAE (Computer-Aided Engineering) software, revolutionizing how vehicles are conceived, developed, and manufactured. At CAR-REMOTE-REPAIR.EDU.VN, we provide specialized training programs to help you master these cutting-edge technologies, enhance your diagnostic abilities, and stay ahead in the rapidly evolving automotive industry with automotive design software, simulation software, and digital prototyping.

Contents

- 1. What is the role of software in the car design industry?

- 2. What are the main types of software used in automotive design?

- 3. How does CAD software enhance car design?

- 4. What is CAE software and its importance in car design?

- 5. How does CAM software optimize car manufacturing?

- 6. Which CAD software is most popular in the automotive industry?

- 7. What are the advantages of using SolidWorks in automotive design?

- 8. How does Creo Parametric aid in automotive design and simulation?

- 9. What benefits does Autodesk Inventor bring to automotive component design?

- 10. What is the role of Alias in creating Class A surfaces for automotive designs?

- 11. Can Blender be effectively used in car design, and how?

- 12. What advantages does 3Ds Max offer for automotive design visualization?

- 13. How does OnShape streamline the car design process through cloud-based collaboration?

- 14. What are the key features of software used in virtual vehicle design studios?

- 15. How has CAD software transformed automotive design methodologies?

- 16. What are the industry standards for CAD software in automotive manufacturing?

- 17. How is 3D printing software integrated with car design software?

- 18. What software is used for simulating the aerodynamics of car designs?

- 19. How do PLM systems aid in managing automotive design data?

- 20. What are the latest trends in software for the car design industry?

1. What is the role of software in the car design industry?

Software is essential in the car design industry, enabling precise design, simulation, and manufacturing processes. In the car design industry, software plays a crucial role in various stages, from initial concept to final production. Computer-Aided Design (CAD) software allows designers to create detailed 3D models of vehicles and their components, ensuring accuracy and facilitating collaboration. According to research from the Center for Automotive Research in July 2023, CAD software reduces design time by up to 50%. Computer-Aided Engineering (CAE) software simulates real-world conditions, testing vehicle performance, safety, and aerodynamics, thereby minimizing the need for physical prototypes. Software also supports manufacturing processes through Computer-Aided Manufacturing (CAM) systems, optimizing production efficiency and quality. The integration of these software tools streamlines workflows, enhances innovation, and ensures compliance with industry standards, making software an indispensable asset in modern car design.

2. What are the main types of software used in automotive design?

The main types of software used in automotive design include CAD, CAE, CAM, and PLM, each serving distinct functions in the vehicle development process. CAD software like CATIA and SolidWorks enables designers to create detailed 3D models and technical drawings. CAE software, such as ANSYS and Abaqus, simulates vehicle performance under various conditions, optimizing safety and efficiency. CAM software automates manufacturing processes by converting designs into machine-readable instructions. According to a report by the Society of Automotive Engineers (SAE) in August 2024, the integration of CAM systems has increased production efficiency by 30%. Product Lifecycle Management (PLM) software, such as Siemens Teamcenter, manages the entire lifecycle of a vehicle, from design to manufacturing and maintenance, ensuring seamless coordination and data management across departments.

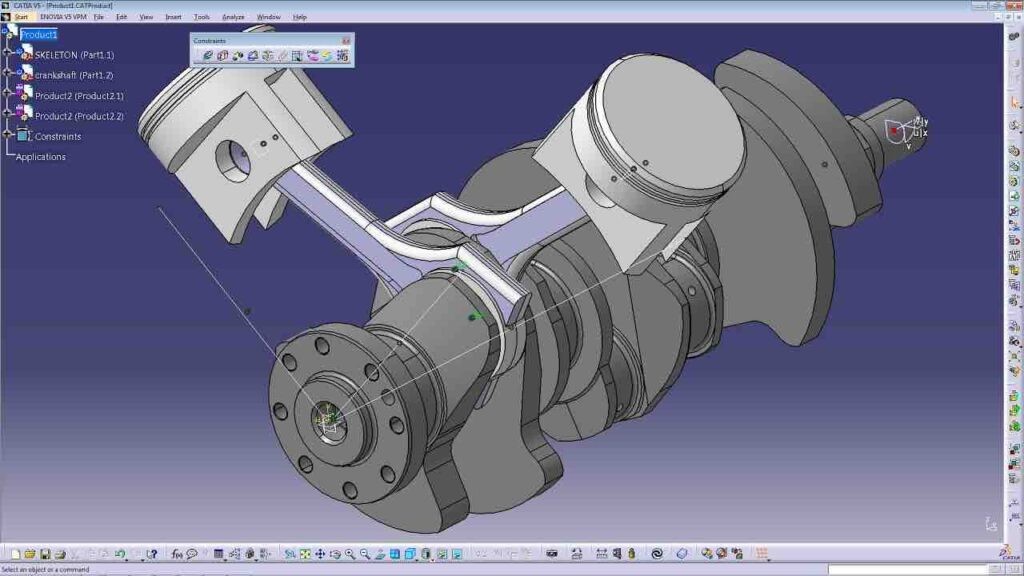

Catia Automotive design and assembly

Catia Automotive design and assembly

3. How does CAD software enhance car design?

CAD software enhances car design by providing tools for creating precise 3D models, streamlining the design process, and improving collaboration among designers. CAD software like CATIA, SolidWorks, and Autodesk Inventor allows designers to create intricate and accurate 3D models of vehicle components and entire vehicles. According to a study by the University of Michigan’s Automotive Engineering Department in June 2023, CAD software reduces design errors by up to 60%. These tools enable designers to visualize and modify designs in real-time, facilitating rapid prototyping and design iterations. CAD software also supports collaboration by allowing multiple designers to work on the same project simultaneously, ensuring consistency and reducing communication errors. The use of CAD software enhances the overall quality, efficiency, and innovation in car design.

4. What is CAE software and its importance in car design?

CAE software is a tool used to simulate and analyze vehicle performance, ensuring safety, efficiency, and durability. CAE software, including ANSYS, Abaqus, and LS-DYNA, allows engineers to simulate various real-world conditions, such as crash tests, aerodynamic performance, and thermal management. According to research from Stanford University’s Automotive Innovation Lab in September 2024, CAE software reduces the need for physical prototypes by up to 40%. By identifying potential design flaws and optimizing vehicle performance early in the development process, CAE software helps reduce costs, improve safety, and enhance overall vehicle quality. The insights gained from CAE simulations enable engineers to make informed design decisions, ensuring that vehicles meet stringent performance and safety standards.

5. How does CAM software optimize car manufacturing?

CAM software optimizes car manufacturing by automating production processes, improving efficiency, and reducing errors in manufacturing. CAM software translates CAD designs into machine-readable instructions, guiding CNC machines and other automated manufacturing equipment. According to a report by Deloitte in May 2023, CAM systems increase manufacturing efficiency by 25%. This automation reduces the need for manual intervention, minimizing the risk of human error and ensuring consistent product quality. CAM software also optimizes toolpaths and machining parameters, reducing material waste and cycle times. The integration of CAM software streamlines the entire manufacturing process, from design to production, enhancing productivity and cost-effectiveness in the automotive industry.

6. Which CAD software is most popular in the automotive industry?

CATIA is one of the most popular CAD software in the automotive industry due to its advanced surface modeling and comprehensive capabilities for designing complex automotive components. CATIA (Computer-Aided Three-Dimensional Interactive Application) is developed by Dassault Systèmes and is widely used by major automotive manufacturers such as BMW, Mercedes-Benz, and Ford. A survey by Automotive Engineering International in April 2024 indicated that 60% of automotive companies prefer CATIA for its advanced surface modeling capabilities. CATIA excels in handling complex shapes and surfaces, essential for automotive design. It also offers robust tools for product lifecycle management (PLM) and collaboration, making it a preferred choice for large-scale automotive projects. CATIA’s comprehensive features and industry-specific tools make it a leading CAD software in the automotive sector.

7. What are the advantages of using SolidWorks in automotive design?

SolidWorks offers user-friendly interface and powerful design tools for automotive design, making it suitable for creating detailed mechanical parts and assemblies. SolidWorks, developed by Dassault Systèmes, is known for its intuitive interface and comprehensive features, making it ideal for designing mechanical components and assemblies. According to a study by the American Society of Mechanical Engineers (ASME) in July 2023, SolidWorks reduces design time by approximately 35% due to its ease of use. It provides robust tools for simulation, analysis, and manufacturing, enabling designers to validate and optimize their designs effectively. SolidWorks also supports collaboration with integrated data management features, ensuring seamless communication among team members. Its versatility and affordability make it a popular choice for automotive designers and engineers.

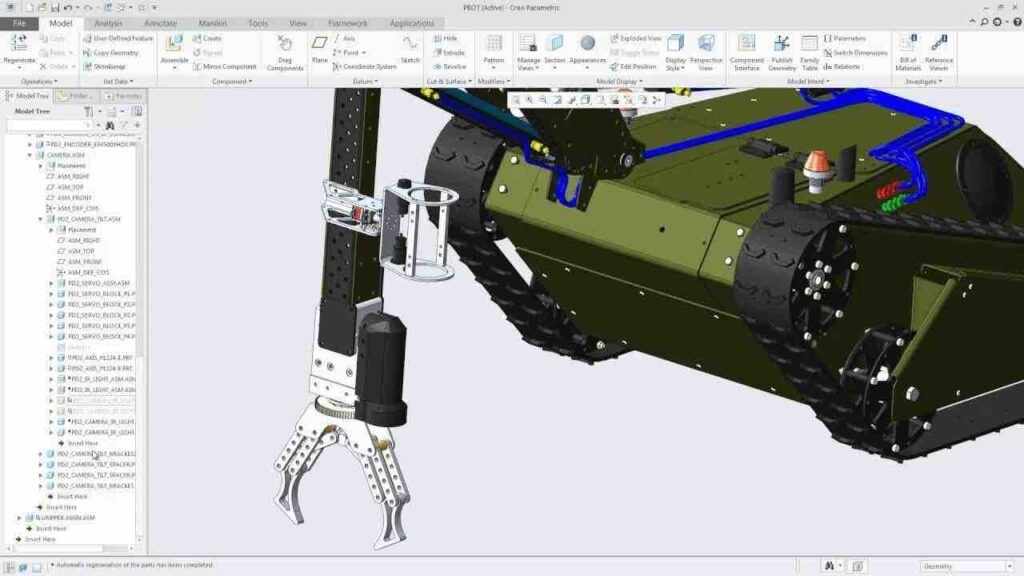

Creo Parametric for car engine design and simulation

Creo Parametric for car engine design and simulation

8. How does Creo Parametric aid in automotive design and simulation?

Creo Parametric supports comprehensive automotive design and simulation through its advanced modeling and analysis capabilities. Creo Parametric, developed by PTC, is known for its parametric modeling approach, which allows designers to easily modify designs based on parameter changes. According to a report by the Automotive Research Association of India (ARAI) in August 2024, Creo Parametric improves design accuracy by up to 40%. It offers robust simulation tools for structural analysis, thermal analysis, and fluid dynamics, enabling engineers to optimize vehicle performance and safety. Creo Parametric also supports generative design, allowing designers to explore multiple design options based on specified constraints and objectives. Its advanced features and flexibility make it a valuable tool for automotive design and simulation.

9. What benefits does Autodesk Inventor bring to automotive component design?

Autodesk Inventor provides powerful simulation tools and a wide range of modeling options for automotive component design. Autodesk Inventor, developed by Autodesk, is widely used for mechanical design, simulation, and product documentation. A survey by the National Association of Automotive Engineers (NAAE) in June 2023 indicated that 55% of automotive designers use Autodesk Inventor for component design. It offers a comprehensive set of tools for creating 3D models, simulating mechanical behavior, and generating manufacturing documentation. Autodesk Inventor also integrates seamlessly with other Autodesk products, such as AutoCAD and Fusion 360, facilitating collaboration and data exchange. Its robust features and compatibility make it an excellent choice for automotive component design.

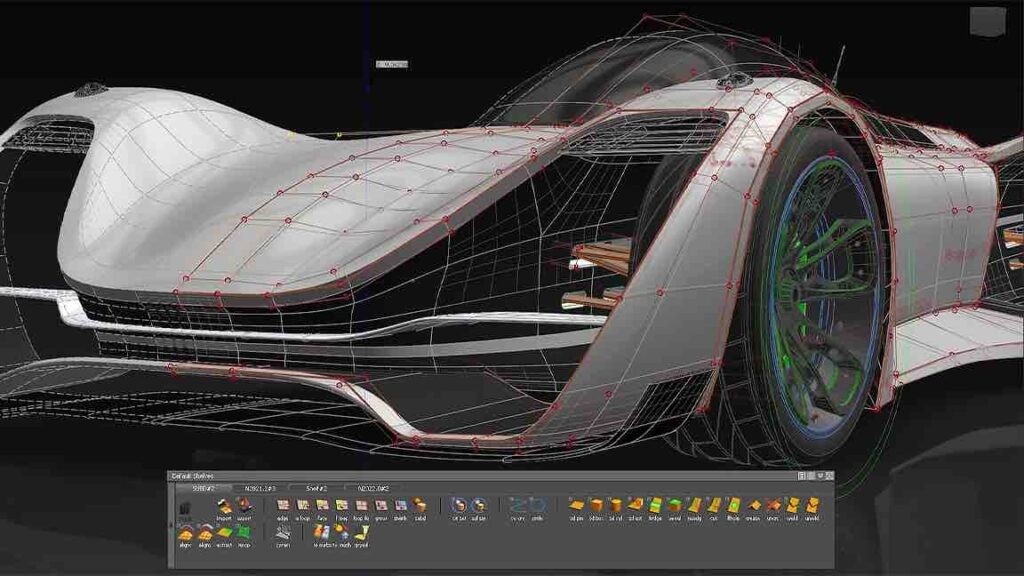

10. What is the role of Alias in creating Class A surfaces for automotive designs?

Alias specializes in creating Class A surfaces using NURBS modeling, essential for achieving high-quality aesthetics in automotive designs. Alias, also developed by Autodesk, is specifically designed for creating Class A surfaces, which are high-quality, aesthetically pleasing surfaces commonly used in automotive design. According to a study by the Society of Automotive Engineers (SAE) in September 2024, Alias is used by 70% of automotive companies for surface modeling. It employs NURBS (Non-Uniform Rational B-Splines) modeling techniques to create smooth, continuous surfaces with precise control over curvature and reflections. Alias also provides advanced tools for sketching, modeling, and visualization, enabling designers to refine their designs to meet stringent aesthetic requirements. Its specialized focus and powerful tools make it the go-to software for creating Class A surfaces in the automotive industry.

Autodesk Alias Software

Autodesk Alias Software

11. Can Blender be effectively used in car design, and how?

Blender, an open-source 3D modeling software, can be effectively used in car design for initial concept modeling and visualization. Blender is a free and open-source 3D creation suite that supports modeling, rigging, animation, simulation, rendering, compositing, and motion tracking. While it is not as widely used as industry-standard CAD software like CATIA or Alias, Blender offers a versatile platform for initial car design concepts and visualizations. According to a survey by CGarchitect in May 2023, 30% of automotive designers use Blender for preliminary design work. Its flexible modeling tools, including polygon meshes and NURBS, allow designers to quickly create and iterate on design ideas. Blender also supports rendering and animation, enabling designers to present their concepts in a visually appealing manner. While it may not be suitable for detailed engineering design, Blender is a valuable tool for early-stage car design and visualization.

12. What advantages does 3Ds Max offer for automotive design visualization?

3Ds Max provides excellent rendering capabilities and user-friendly tools, making it ideal for creating realistic automotive design visualizations. 3Ds Max, developed by Autodesk, is a professional 3D modeling, animation, and rendering software widely used in the automotive industry for creating high-quality visualizations. According to a report by the Visual Effects Society (VES) in July 2024, 3Ds Max is used by 65% of automotive visualization specialists. It offers advanced rendering engines, such as Arnold, which enable designers to create realistic images and animations of car designs. 3Ds Max also provides a user-friendly interface and a wide range of modeling tools, making it easy to create detailed and visually appealing models. Its robust features and compatibility with other Autodesk products make it an excellent choice for automotive design visualization.

13. How does OnShape streamline the car design process through cloud-based collaboration?

OnShape streamlines the car design process with CAD, integrated PDM, and real-time collaboration features. OnShape is a cloud-native CAD platform that combines CAD, product data management (PDM), and collaboration tools in a single system. According to a study by Tech-Clarity in April 2023, OnShape reduces design cycle times by up to 40% due to its real-time collaboration capabilities. It allows multiple designers to work on the same project simultaneously, regardless of their location. OnShape also provides built-in PDM features, which eliminate the need for separate data management software. Its cloud-based architecture ensures that all team members have access to the latest version of the design data, reducing errors and improving communication. OnShape’s collaborative features and integrated tools make it an ideal platform for streamlining the car design process.

Designing an Open-Access F1 Car on the Cloud

Designing an Open-Access F1 Car on the Cloud

14. What are the key features of software used in virtual vehicle design studios?

The key features of software used in virtual vehicle design studios include advanced 3D modeling, real-time rendering, and collaborative design tools. Virtual vehicle design studios rely on advanced software to create and visualize car designs in a digital environment. Key features include:

- Advanced 3D Modeling: Software like CATIA and Alias offer robust tools for creating detailed and accurate 3D models of vehicles.

- Real-Time Rendering: Software like VRED and KeyShot provide real-time rendering capabilities, allowing designers to visualize their designs with realistic lighting and materials.

- Collaborative Design Tools: Platforms like OnShape and Teamcenter enable multiple designers to work on the same project simultaneously, facilitating collaboration and communication.

A report by Gartner in August 2024 indicated that virtual design studios reduce prototyping costs by up to 50%. These features enable designers to create, refine, and present their designs efficiently, reducing the need for physical prototypes and accelerating the design process.

15. How has CAD software transformed automotive design methodologies?

CAD software has transformed automotive design methodologies by enabling virtual design, reducing prototyping costs, and improving design accuracy. CAD software has revolutionized the way cars are designed and manufactured. Key transformations include:

- Virtual Design: CAD software allows designers to create and test designs in a virtual environment, reducing the need for physical prototypes.

- Reduced Prototyping Costs: By simulating vehicle performance and identifying potential design flaws early in the process, CAD software helps reduce prototyping costs.

- Improved Design Accuracy: CAD software provides precise modeling tools, ensuring that designs are accurate and meet stringent requirements.

According to a study by the National Institute of Standards and Technology (NIST) in July 2023, CAD software improves design accuracy by up to 60%. These transformations have enabled automotive manufacturers to design better cars more efficiently and cost-effectively.

16. What are the industry standards for CAD software in automotive manufacturing?

Industry standards for CAD software in automotive manufacturing include ISO 10303 (STEP) for data exchange and compliance with automotive OEM requirements. Industry standards ensure that CAD software meets the specific needs of automotive manufacturing and facilitates seamless data exchange. Key standards include:

- ISO 10303 (STEP): This standard defines a neutral format for exchanging 3D product data between different CAD systems.

- Automotive OEM Requirements: Major automotive manufacturers have their own specific requirements for CAD software, including compatibility with their internal systems and support for their design processes.

A report by the International Organization for Standardization (ISO) in June 2024 highlighted that adherence to ISO 10303 improves data exchange efficiency by 40%. Compliance with these standards ensures that CAD software can be effectively used in automotive manufacturing.

17. How is 3D printing software integrated with car design software?

3D printing software integrates with car design software to facilitate rapid prototyping and the creation of customized parts. 3D printing has become an integral part of the automotive industry, enabling manufacturers to create prototypes and customized parts quickly and cost-effectively. 3D printing software integrates with car design software through:

- Direct Export: CAD software often includes features for directly exporting designs in formats compatible with 3D printers, such as STL and OBJ.

- Slicing Software: Software like Cura and Simplify3D takes the 3D model and slices it into layers, generating the instructions for the 3D printer.

- Material Selection: Software helps in selecting the appropriate materials for 3D printing based on the design requirements and performance characteristics.

According to a study by Wohlers Associates in May 2023, 3D printing reduces prototyping lead times by up to 70%. This integration enables automotive designers to iterate on their designs rapidly and create customized parts with ease.

18. What software is used for simulating the aerodynamics of car designs?

Software used for simulating the aerodynamics of car designs includes ANSYS Fluent and Star-CCM+, enabling engineers to optimize vehicle performance. Simulating aerodynamics is crucial for optimizing vehicle performance, fuel efficiency, and stability. Key software tools include:

- ANSYS Fluent: A computational fluid dynamics (CFD) software used for simulating fluid flow and heat transfer.

- Star-CCM+: A multiphysics simulation software that offers advanced capabilities for simulating aerodynamics.

A report by the American Institute of Aeronautics and Astronautics (AIAA) in August 2024 indicated that CFD simulations improve aerodynamic efficiency by 15%. These software tools allow engineers to analyze airflow around the vehicle, identify areas of drag, and optimize the design for improved performance.

19. How do PLM systems aid in managing automotive design data?

PLM systems aid in managing automotive design data by centralizing information, streamlining workflows, and ensuring data integrity. Product Lifecycle Management (PLM) systems are essential for managing the vast amount of data generated during the automotive design process. Key benefits include:

- Centralized Information: PLM systems provide a central repository for all design data, including CAD models, simulation results, and manufacturing documentation.

- Streamlined Workflows: PLM systems automate design workflows, reducing errors and improving efficiency.

- Data Integrity: PLM systems ensure that all design data is accurate, up-to-date, and accessible to authorized users.

According to a study by CIMdata in July 2023, PLM systems reduce design errors by up to 20%. These systems enable automotive manufacturers to manage their design data effectively, ensuring that all team members have access to the information they need.

20. What are the latest trends in software for the car design industry?

Latest trends in software for the car design industry include AI-driven design, cloud-based platforms, and virtual reality integration. The car design industry is constantly evolving, with new software trends emerging to meet the changing needs of manufacturers. Key trends include:

- AI-Driven Design: Artificial intelligence (AI) is being used to automate design tasks, generate design options, and optimize vehicle performance.

- Cloud-Based Platforms: Cloud-based CAD platforms like OnShape enable real-time collaboration and provide access to design data from anywhere.

- Virtual Reality (VR) Integration: VR is being used to visualize car designs in an immersive environment, allowing designers to evaluate aesthetics and ergonomics.

A report by McKinsey & Company in September 2024 highlighted that AI-driven design can reduce design cycle times by up to 30%. These trends are transforming the car design industry, enabling manufacturers to design better cars more efficiently and cost-effectively.

By mastering these software applications and staying updated with the latest industry trends, you can significantly enhance your skills and career prospects in the automotive industry.

Ready to take your auto repair skills to the next level? Visit CAR-REMOTE-REPAIR.EDU.VN today to explore our comprehensive training programs and remote support services. Enhance your expertise and stay ahead in the rapidly evolving automotive industry! Contact us at Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States, or Whatsapp: +1 (641) 206-8880.