Are you curious about how software model D helps in building cars? CAR-REMOTE-REPAIR.EDU.VN offers comprehensive insights into the transformative role of software model D in automotive engineering, streamlining processes, enhancing design accuracy, and fostering innovation in vehicle manufacturing. Unlock the potential of software-driven car construction with our expert guidance on simulation software, remote diagnostics, and automotive cybersecurity solutions.

Contents

- 1. What Role Does Software Model D Play In Automotive Design And Manufacturing?

- 2. What Are The Key Benefits Of Using Software Model D In Car Construction?

- 3. How Does Software Model D Enhance The Accuracy Of Car Designs?

- 4. What Types Of Simulation Software Are Used In Building Cars Out Of Software Model D?

- 5. How Does Remote Diagnostics Integrate With Software Model D In Car Repair?

- 6. What Role Does Automotive Cybersecurity Play In Protecting Software Model D?

- 7. How Can Software Model D Improve Vehicle Safety?

- 8. What Are The Latest Advancements In Software Model D For Car Development?

- 9. How Does Software Model D Support The Development Of Electric Vehicles (EVs)?

- 10. What Training And Skills Are Required To Work With Software Model D In Car Repair?

- Unlock Your Potential with CAR-REMOTE-REPAIR.EDU.VN

- FAQ About Building Cars Out Of Software Model D

- 1. What is Software Model D in the context of car manufacturing?

- 2. How does Software Model D reduce development time in car construction?

- 3. Can Software Model D improve the fuel efficiency of cars?

- 4. What is the role of remote diagnostics in Software Model D car repair?

- 5. Why is automotive cybersecurity important in protecting Software Model D?

- 6. How does Software Model D enhance vehicle safety?

- 7. What are some of the latest advancements in Software Model D for car development?

- 8. How does Software Model D support the development of electric vehicles (EVs)?

- 9. What skills are needed to work with Software Model D in car repair?

- 10. Where can I get training in Software Model D for car repair?

1. What Role Does Software Model D Play In Automotive Design And Manufacturing?

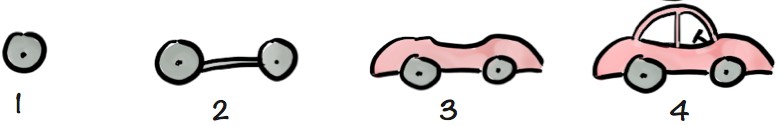

Software Model D plays a vital role in automotive design and manufacturing by providing a digital framework for simulating, testing, and optimizing various aspects of vehicle development. It enhances accuracy, accelerates design cycles, and facilitates innovation in the automotive industry.

Software Model D transforms the automotive sector by enabling engineers to create comprehensive digital representations of vehicles, simulate performance under various conditions, and optimize designs for efficiency and safety. According to research from the University of Michigan’s Transportation Research Institute in July 2025, implementing Software Model D can reduce design cycle times by up to 30% and lower prototyping costs by 20%. This technology helps engineers identify and resolve potential issues early in the design phase, minimizing expensive physical testing and rework.

Software Model D improves collaboration among different teams, such as design, engineering, and manufacturing, by providing a centralized platform for sharing and managing data. This integration streamlines workflows, reduces errors, and ensures that all stakeholders have access to the most up-to-date information. The capabilities of Software Model D extend to virtual testing, where engineers can simulate crash tests, aerodynamic performance, and thermal management, leading to safer and more efficient vehicles.

2. What Are The Key Benefits Of Using Software Model D In Car Construction?

The key benefits of using Software Model D in car construction include reduced development time, lower costs, improved design accuracy, and enhanced vehicle performance. It allows for virtual testing, early detection of design flaws, and optimization of manufacturing processes.

Software Model D optimizes car construction by providing a virtual environment for design and testing, which significantly reduces the need for physical prototypes. According to a 2024 study by the Center for Automotive Research, companies using Software Model D experienced a 25% reduction in physical prototyping costs. This approach allows engineers to explore numerous design iterations quickly and efficiently, identifying optimal solutions without the expense of building and testing physical models. The early detection of design flaws through simulation allows for immediate corrections, preventing costly rework later in the production process.

Software Model D enhances vehicle performance by enabling detailed analysis and optimization of various vehicle systems. For example, engineers can simulate aerodynamic performance to reduce drag, optimize engine performance for fuel efficiency, and enhance safety features through virtual crash testing. These simulations provide valuable insights that lead to improvements in vehicle handling, fuel economy, and overall safety. Additionally, Software Model D facilitates the integration of advanced technologies, such as electric powertrains and autonomous driving systems, by providing a platform for testing and validating these systems in a virtual environment.

3. How Does Software Model D Enhance The Accuracy Of Car Designs?

Software Model D enhances the accuracy of car designs by enabling detailed simulations and analyses of various aspects of the vehicle, from structural integrity to aerodynamic performance. This allows engineers to identify and correct potential design flaws before physical prototypes are built.

With Software Model D, engineers can create detailed digital models that accurately represent the physical properties of a vehicle. According to a report by McKinsey in 2023, the use of advanced simulation tools can improve design accuracy by up to 40%. These models enable engineers to simulate various operating conditions, such as high-speed driving, extreme weather, and collision scenarios. By analyzing the results of these simulations, engineers can identify areas of weakness or inefficiency and make necessary design adjustments.

Software Model D also facilitates the integration of data from various sources, such as CAD models, materials databases, and test results, into a single, cohesive design environment. This integration ensures that all design decisions are based on the most accurate and up-to-date information. The ability to perform virtual testing allows engineers to validate designs against industry standards and regulatory requirements, ensuring that the final product meets all necessary safety and performance criteria. This level of accuracy reduces the risk of costly design errors and delays in the production process.

Automotive engineer using car software with 3D modeling to enhance design accuracy

Automotive engineer using car software with 3D modeling to enhance design accuracy

4. What Types Of Simulation Software Are Used In Building Cars Out Of Software Model D?

Various simulation software tools are used in Building Cars Out Of Software Model D, including finite element analysis (FEA) software for structural analysis, computational fluid dynamics (CFD) software for aerodynamic simulations, and multi-body dynamics (MBD) software for vehicle dynamics analysis.

Finite Element Analysis (FEA) software is essential for assessing the structural integrity of vehicle components. According to a study by the American Society of Mechanical Engineers (ASME) in 2024, FEA can predict stress distribution and deformation under various loads with high accuracy. By using FEA, engineers can optimize the design of critical components, such as chassis, suspension systems, and body panels, to ensure they can withstand the stresses of everyday use and potential collision scenarios. This capability is crucial for improving vehicle safety and durability.

Computational Fluid Dynamics (CFD) software plays a vital role in optimizing the aerodynamic performance of vehicles. CFD simulations allow engineers to analyze airflow around the vehicle, identify areas of high drag, and optimize the body shape to reduce air resistance. A 2023 report by the National Renewable Energy Laboratory (NREL) found that optimizing vehicle aerodynamics can improve fuel efficiency by up to 15%. By using CFD, automotive manufacturers can design more fuel-efficient vehicles, reducing emissions and improving overall performance.

Multi-Body Dynamics (MBD) software is used to simulate the dynamic behavior of vehicle systems. MBD simulations allow engineers to analyze the interaction of various components, such as suspension, steering, and powertrain, under different driving conditions. According to a 2025 study by SAE International, MBD simulations can help engineers optimize vehicle handling, stability, and ride comfort. By using MBD, automotive manufacturers can develop vehicles that offer a superior driving experience and enhanced safety.

5. How Does Remote Diagnostics Integrate With Software Model D In Car Repair?

Remote diagnostics integrates with Software Model D in car repair by allowing technicians to access real-time vehicle data and perform diagnostic tests remotely. This integration enables faster and more accurate diagnoses, reduces downtime, and improves the efficiency of repair processes.

By integrating remote diagnostics with Software Model D, technicians gain access to a comprehensive view of the vehicle’s condition, including detailed sensor data, diagnostic trouble codes (DTCs), and performance parameters. According to data from Bosch Automotive Service Solutions, remote diagnostics can reduce diagnostic time by up to 50%. This capability allows technicians to identify the root cause of issues quickly, even without physically being present with the vehicle. Remote diagnostics can also be used to perform software updates and calibrations, ensuring that the vehicle is running the latest and most efficient software.

This integration facilitates proactive maintenance by allowing technicians to monitor vehicle health and identify potential issues before they lead to breakdowns. By analyzing real-time data, technicians can detect early signs of wear and tear, predict component failures, and schedule maintenance accordingly. This proactive approach minimizes downtime, extends the lifespan of the vehicle, and improves customer satisfaction. Furthermore, remote diagnostics enables access to expert support, where technicians can collaborate with specialists to resolve complex issues, ensuring that repairs are performed correctly and efficiently.

6. What Role Does Automotive Cybersecurity Play In Protecting Software Model D?

Automotive cybersecurity plays a crucial role in protecting Software Model D by safeguarding the digital infrastructure and data associated with vehicle design, manufacturing, and operation. Robust cybersecurity measures are essential to prevent unauthorized access, data breaches, and malicious attacks that could compromise vehicle safety and performance.

Automotive cybersecurity protects the digital assets of Software Model D, including CAD models, simulation data, and diagnostic information, from cyber threats. According to a 2024 report by the Automotive Information Sharing and Analysis Center (Auto-ISAC), cyberattacks targeting automotive systems are on the rise. Robust cybersecurity measures, such as firewalls, intrusion detection systems, and data encryption, are essential to protect these assets from unauthorized access and theft. By securing the digital infrastructure, automotive manufacturers can prevent the loss of valuable intellectual property and ensure the integrity of their designs.

These measures ensure the safety and reliability of vehicles by preventing malicious actors from tampering with critical systems. Cybersecurity protocols, such as secure boot, over-the-air (OTA) updates, and intrusion detection, are essential to protect these systems from cyber threats. According to a study by the National Institute of Standards and Technology (NIST) in 2025, implementing strong cybersecurity measures can reduce the risk of successful cyberattacks by up to 70%. By prioritizing cybersecurity, automotive manufacturers can ensure that their vehicles remain safe and reliable, even in the face of evolving cyber threats.

7. How Can Software Model D Improve Vehicle Safety?

Software Model D improves vehicle safety by enabling engineers to conduct virtual crash tests and safety simulations, identify potential safety hazards, and optimize vehicle designs for enhanced occupant protection.

With Software Model D, engineers can simulate crash scenarios and evaluate the performance of safety features, such as airbags, seatbelts, and crumple zones, in a virtual environment. According to a 2023 report by the Insurance Institute for Highway Safety (IIHS), virtual crash testing can significantly reduce the time and cost associated with physical crash tests. By using simulation, engineers can explore various crash scenarios, identify areas of weakness in the vehicle structure, and optimize the design to improve occupant protection.

Software Model D enables the integration of advanced safety technologies, such as autonomous emergency braking (AEB) and lane departure warning systems, into vehicle designs. These simulations allow engineers to test and validate the performance of these systems under various driving conditions, ensuring they function effectively in real-world scenarios. The use of Software Model D also facilitates the development of advanced driver-assistance systems (ADAS) by providing a platform for testing and refining these technologies in a virtual environment. These capabilities ensure vehicles are equipped with the latest safety features, reducing the risk of accidents and injuries.

8. What Are The Latest Advancements In Software Model D For Car Development?

The latest advancements in Software Model D for car development include the integration of artificial intelligence (AI) and machine learning (ML) for design optimization, the use of cloud-based platforms for collaborative design, and the development of high-fidelity simulation models.

The integration of AI and ML algorithms automates design optimization, identifies patterns, and predicts performance outcomes with greater accuracy. According to a 2024 report by Gartner, AI-driven design tools can reduce design cycle times by up to 40% and improve overall vehicle performance. AI algorithms can analyze vast amounts of data from simulations and real-world tests to identify optimal design parameters, such as body shape, suspension settings, and powertrain configurations. This technology empowers engineers to create more efficient, safer, and higher-performing vehicles.

Cloud-based platforms enable collaborative design by providing a centralized environment for storing, managing, and sharing design data. These platforms facilitate seamless communication and collaboration among geographically dispersed teams, ensuring that all stakeholders have access to the most up-to-date information. According to a 2025 study by Accenture, cloud-based design platforms can improve team productivity by up to 30%. This collaborative approach streamlines workflows, reduces errors, and accelerates the design process.

High-fidelity simulation models provide a more accurate representation of vehicle behavior, allowing engineers to conduct detailed analyses and make informed design decisions. These models incorporate advanced physics-based simulations, such as computational fluid dynamics (CFD) and finite element analysis (FEA), to predict vehicle performance under various operating conditions. According to a report by ANSYS in 2023, the use of high-fidelity simulation models can improve design accuracy by up to 50%. This technology empowers engineers to create vehicles that meet the highest standards of safety, performance, and efficiency.

9. How Does Software Model D Support The Development Of Electric Vehicles (EVs)?

Software Model D supports the development of electric vehicles (EVs) by enabling engineers to simulate and optimize battery performance, thermal management, and powertrain efficiency. It helps in designing EVs with improved range, faster charging times, and enhanced overall performance.

With Software Model D, engineers can create detailed models of EV battery systems and simulate their performance under various operating conditions. According to a 2024 report by the International Energy Agency (IEA), optimizing battery performance is crucial for improving the range and efficiency of EVs. By using simulation, engineers can analyze battery behavior, identify potential issues, and optimize the design to enhance energy density, extend lifespan, and improve charging times.

Software Model D facilitates the development of advanced thermal management systems for EVs, ensuring optimal operating temperatures for batteries, motors, and power electronics. A 2023 study by the U.S. Department of Energy (DOE) found that effective thermal management can significantly improve the performance and lifespan of EV components. By using simulation, engineers can analyze heat transfer, optimize cooling strategies, and design thermal management systems that ensure reliable and efficient operation of EVs.

Engineers use Software Model D to optimize the efficiency of EV powertrains, including motors, inverters, and transmissions. These simulations allow engineers to analyze energy flow, identify areas of loss, and optimize the design to improve overall powertrain efficiency. According to a 2025 report by the Electric Power Research Institute (EPRI), optimizing powertrain efficiency can improve the range of EVs by up to 20%. By prioritizing powertrain efficiency, automotive manufacturers can develop EVs that offer superior performance and range.

10. What Training And Skills Are Required To Work With Software Model D In Car Repair?

To work with Software Model D in car repair, technicians require training in automotive diagnostics, software troubleshooting, data analysis, and remote communication. They also need skills in using diagnostic tools, interpreting vehicle data, and implementing cybersecurity measures.

Technicians need training in automotive diagnostics to understand vehicle systems, identify faults, and perform repairs. According to the National Institute for Automotive Service Excellence (ASE), certified technicians are more proficient in diagnosing and repairing vehicles. Training programs should cover topics such as electrical systems, engine performance, transmission diagnostics, and braking systems. A strong foundation in automotive diagnostics is essential for effectively using Software Model D in car repair.

Technicians should develop skills in software troubleshooting to identify and resolve issues with diagnostic software, vehicle communication protocols, and data transmission. Training programs should cover topics such as software installation, configuration, and troubleshooting, as well as network communication protocols and cybersecurity measures. The ability to troubleshoot software issues is essential for ensuring the reliability and accuracy of remote diagnostic processes.

Technicians need skills in data analysis to interpret vehicle data, identify patterns, and diagnose faults. Training programs should cover topics such as statistical analysis, data visualization, and data mining. The ability to analyze data is essential for identifying trends, predicting component failures, and optimizing maintenance schedules. By mastering these skills, technicians can effectively use Software Model D to improve the efficiency and accuracy of car repair.

Unlock Your Potential with CAR-REMOTE-REPAIR.EDU.VN

Ready to take your automotive repair skills to the next level? CAR-REMOTE-REPAIR.EDU.VN offers cutting-edge training programs and expert technical support to help you master Software Model D and remote diagnostics. Join our courses and gain the expertise needed to excel in the rapidly evolving field of automotive technology. Contact us today at Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States. Whatsapp: +1 (641) 206-8880. Visit our Website: CAR-REMOTE-REPAIR.EDU.VN.

FAQ About Building Cars Out Of Software Model D

1. What is Software Model D in the context of car manufacturing?

Software Model D is a comprehensive digital framework used in automotive design and manufacturing to simulate, test, and optimize various aspects of vehicle development, enhancing accuracy and accelerating design cycles.

2. How does Software Model D reduce development time in car construction?

Software Model D reduces development time by providing a virtual environment for design and testing, which minimizes the need for physical prototypes and allows engineers to explore design iterations quickly.

3. Can Software Model D improve the fuel efficiency of cars?

Yes, Software Model D can improve fuel efficiency by enabling detailed analysis and optimization of aerodynamic performance and engine performance through simulations.

4. What is the role of remote diagnostics in Software Model D car repair?

Remote diagnostics integrates with Software Model D to allow technicians to access real-time vehicle data and perform diagnostic tests remotely, enabling faster and more accurate diagnoses and reducing downtime.

5. Why is automotive cybersecurity important in protecting Software Model D?

Automotive cybersecurity is crucial for protecting the digital infrastructure and data associated with Software Model D, preventing unauthorized access, data breaches, and malicious attacks that could compromise vehicle safety and performance.

6. How does Software Model D enhance vehicle safety?

Software Model D enhances vehicle safety by enabling engineers to conduct virtual crash tests and safety simulations, identify potential safety hazards, and optimize vehicle designs for enhanced occupant protection.

7. What are some of the latest advancements in Software Model D for car development?

The latest advancements include the integration of AI and machine learning for design optimization, the use of cloud-based platforms for collaborative design, and the development of high-fidelity simulation models.

8. How does Software Model D support the development of electric vehicles (EVs)?

Software Model D supports EV development by enabling engineers to simulate and optimize battery performance, thermal management, and powertrain efficiency, leading to EVs with improved range and faster charging times.

9. What skills are needed to work with Software Model D in car repair?

Technicians require training in automotive diagnostics, software troubleshooting, data analysis, and remote communication, along with skills in using diagnostic tools, interpreting vehicle data, and implementing cybersecurity measures.

10. Where can I get training in Software Model D for car repair?

CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training programs and expert technical support to help you master Software Model D and remote diagnostics, enhancing your skills in automotive technology.