Cad Software For Cars is essential for modern automotive repair, allowing technicians to design, analyze, and modify vehicle components with precision. At CAR-REMOTE-REPAIR.EDU.VN, we understand the importance of staying updated with the latest advancements in automotive technology, so choosing the right CAD (Computer-Aided Design) software for automotive applications can significantly improve your efficiency and accuracy in the repair process. Enhance your skills with our specialized training programs, focusing on digital automotive modeling, automotive component designs, and automotive CAD modeling software.

Contents

- 1. What Is CAD Software For Cars And Why Is It Important?

- 2. What Are The Key Features To Look For In CAD Software For Cars?

- 3. What Are The Top CAD Software Options For Automotive Repair Professionals?

- 3.1 CATIA

- 3.2 SolidWorks

- 3.3 Creo Parametric

- 3.4 Autodesk Inventor

- 3.5 Rhino

- 3.6 Autodesk Alias

- 3.7 Blender

- 3.8 3Ds Max

- 3.9 OnShape

- 4. How Can CAD Software Improve The Efficiency Of Automotive Repair Processes?

- 5. What Role Does 3D Printing Play In Conjunction With CAD Software In Automotive Repair?

- 6. What Are The Advantages Of Using CAD Software For Designing Custom Automotive Parts?

- 7. How Can Technicians Learn To Use CAD Software Effectively For Automotive Repair?

- 8. What Are The Emerging Trends In CAD Software For The Automotive Industry?

- 9. How Does CAR-REMOTE-REPAIR.EDU.VN Integrate CAD Software Into Its Training Programs?

- 10. What Are Some Common Challenges Faced When Implementing CAD Software In Automotive Repair, And How Can They Be Addressed?

- 11. How Can CAD Software Help With Remote Automotive Repair Services?

- 12. What Types Of Automotive Components Can Be Designed And Repaired Using CAD Software?

- 13. What Is The Role Of CAD Software In Automotive Restorations?

- 14. What Is The Difference Between 2D And 3D CAD Software, And Which Is More Suitable For Automotive Repair?

- 15. How Can Automotive Businesses Justify The Investment In CAD Software And Training?

- 16. What Are Some Best Practices For Managing CAD Files And Designs In An Automotive Repair Shop?

- 17. How Can CAD Software Assist In Diagnosing Automotive Problems?

- 18. What Are The Legal Considerations When Using CAD Software For Automotive Design And Repair?

- 19. How Can CAD Software Be Used To Create Custom Modifications For Vehicles?

- 20. How Can CAR-REMOTE-REPAIR.EDU.VN Help Automotive Technicians Stay Up-To-Date With The Latest CAD Software Technologies?

- FAQ About CAD Software For Cars

- 1. What is the primary benefit of using CAD software in automotive design?

- 2. Which CAD software is best for designing Class A surfaces in automotive design?

- 3. Can beginners learn to use CAD software for automotive repair?

- 4. Is cloud-based CAD software a good option for automotive repair shops?

- 5. How does 3D printing enhance the use of CAD software in automotive repair?

- 6. What are the key features to look for when choosing CAD software for automotive applications?

- 7. How can CAD software help with remote automotive repair services?

- 8. What types of training are available for learning CAD software for automotive repair?

- 9. How can automotive businesses justify the investment in CAD software and training?

- 10. What emerging trends in CAD software should automotive technicians be aware of?

1. What Is CAD Software For Cars And Why Is It Important?

CAD software for cars is a digital tool used to design, modify, analyze, and optimize vehicle components and systems, and it’s crucial because it enhances precision, efficiency, and innovation in automotive repair. This encompasses everything from individual parts to entire vehicle models.

- Enhanced Precision: CAD software allows for detailed and accurate design, minimizing errors in the repair and manufacturing processes.

- Improved Efficiency: Digital designs can be quickly modified and tested, reducing the time and cost associated with physical prototypes.

- Innovative Solutions: Technicians can explore new designs and solutions, leading to more effective and innovative repair strategies.

According to a 2023 report by Grand View Research, the global CAD software market is expected to reach $14.24 billion by 2030, growing at a CAGR of 6.2% from 2023 to 2030. This growth is driven by the increasing adoption of CAD in the automotive industry for design, prototyping, and manufacturing.

2. What Are The Key Features To Look For In CAD Software For Cars?

The key features to look for include 3D modeling, simulation capabilities, compatibility, user-friendly interface, and integration with other systems, ensuring efficient and accurate automotive repair processes.

- 3D Modeling: Essential for creating detailed and realistic models of car parts and assemblies.

- Simulation Capabilities: Allows for testing designs under various conditions to identify potential issues early on.

- Compatibility: Must be compatible with various file formats and other software used in automotive repair.

- User-Friendly Interface: Reduces the learning curve and increases productivity.

- Integration with Other Systems: Seamlessly integrates with CAM (Computer-Aided Manufacturing) and CAE (Computer-Aided Engineering) software.

A study by the University of Michigan’s Transportation Research Institute in 2022 found that CAD software with advanced simulation capabilities can reduce prototyping costs by up to 40% and decrease time-to-market by 20% for new automotive components.

3. What Are The Top CAD Software Options For Automotive Repair Professionals?

The top CAD software options include CATIA, SolidWorks, Creo Parametric, Autodesk Inventor, and Rhino, each offering unique features and capabilities tailored to the automotive industry.

| Software | Key Features | Pros | Cons |

|---|---|---|---|

| CATIA | Advanced surface modeling, CAE integration, PLM capabilities | Best-in-class surface modeling, comprehensive solution for design and integration, suitable for complex geometries | Expensive, steep learning curve |

| SolidWorks | User-friendly interface, versatile capabilities for design and mechanical part creation, virtual validation | Easier-to-use interface than CATIA, ideal for design and mechanical part creation, reduces manufacturing time | Primarily CAD modeling software, not as diverse as CATIA |

| Creo Parametric | Focus on solid modeling, simulation of manufacturing processes, user-friendly interface | Ideal for producing precise 3D models, allows quick simulation of the entire manufacturing process, simple to use | Target user is experienced professional working with complex geometries |

| Autodesk Inventor | Stable performance with heavy assemblies, wide range of modeling options, powerful simulation tools | Provides stable performance even with complex assemblies, ideal for automotive component designs, includes a wide range of modeling options and simulation tools | Subscription-based pricing |

| Rhino | NURBS curves and surfaces, subdivision geometry, easy to use and learn | Relatively easy to use and learn, can create high-quality models optimized for 3D printing, versatile for various applications | May require additional plugins for advanced automotive-specific features |

| Autodesk Alias | Class A surface generation, industrial and automotive design sketching, modeling, surface design, and visualization | Best for designing Class A surfaces, suitable for all types of design work, used by top automotive companies | Specialized for surface design, may require additional software for complete automotive design |

| Blender | Free and open-source, modeling, texturing, rigging, animation, lighting | Free and open-source, capable of modeling complex geometries, reduces design time | Primarily for character modeling, may require additional tools for precise automotive design |

| 3Ds Max | Fundamentals of surface modeling, advanced poly-modeling techniques, realistic car designs | Excellent choice for beginners, teaches fundamentals of surface modeling, creates high-quality renderings, supports Virtual Reality | Primarily for rendering and visualization, may require additional software for detailed automotive design |

| OnShape | Cloud-native, full-featured CAD, integrated PDM, and enterprise analytics | Combines CAD, PDM, and enterprise analytics, allows for quick, collaborative, and secure creation of high-quality products, modernizes product design process | Cloud-based, may require a stable internet connection |

According to a survey conducted by Siemens in 2024, 85% of automotive manufacturers use at least two different CAD software solutions to cover various aspects of design, simulation, and manufacturing.

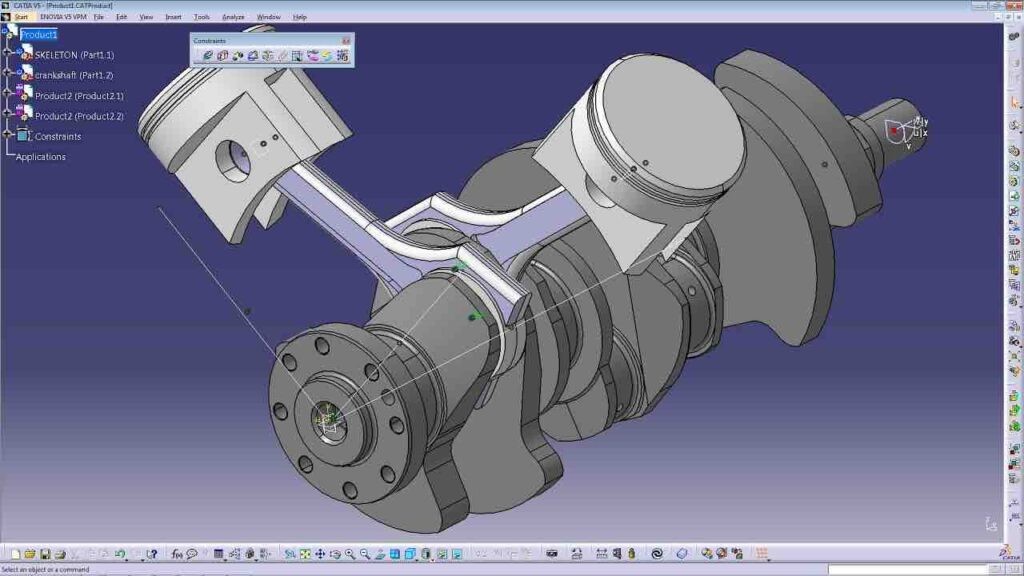

3.1 CATIA

CATIA (Computer-Aided Three Dimensional Interactive Application) is a multi-platform software suite developed by Dassault Systèmes.

Catia Automotive design and assembly

Catia Automotive design and assembly

- Best For: Complex surface modeling and comprehensive design integration.

- Why Choose CATIA: Its advanced capabilities make it ideal for designing intricate automotive components and managing the entire product lifecycle.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Mastering CATIA can significantly enhance your ability to work on high-end automotive projects, making you a valuable asset in the industry.

3.2 SolidWorks

SolidWorks, also developed by Dassault Systèmes, is a solid modeling software known for its user-friendly interface and versatile capabilities.

- Best For: Mechanical part creation and virtual validation.

- Why Choose SolidWorks: Its ease of use and ability to quickly validate designs make it a practical choice for automotive repair and design.

- CAR-REMOTE-REPAIR.EDU.VN Insight: SolidWorks is an excellent tool for technicians who need to create and modify parts efficiently, reducing manufacturing time.

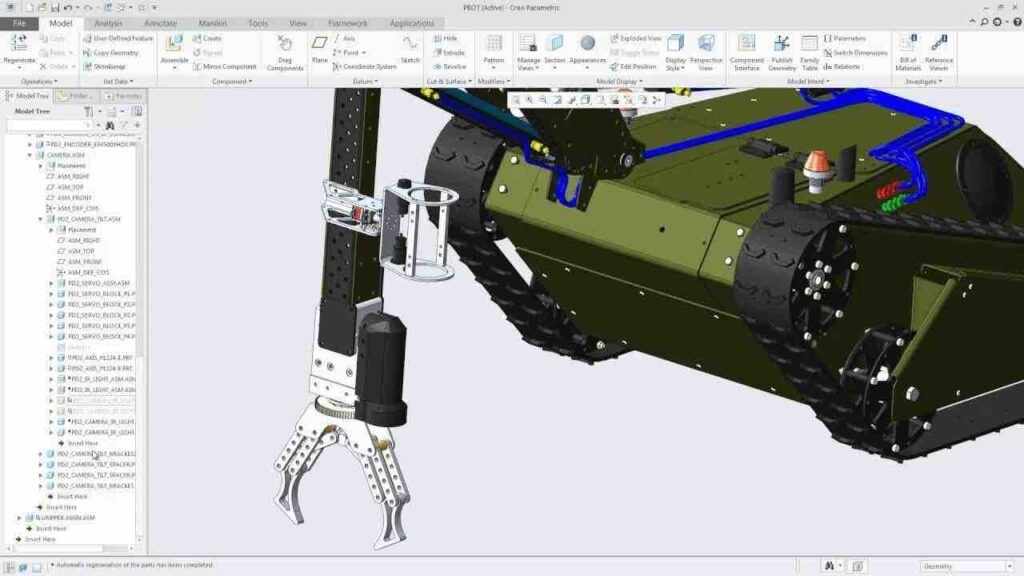

3.3 Creo Parametric

Creo Parametric by PTC is a solid modeling software that has been a major competitor in the CAD market.

Creo Parametric for car engine design and simulation

Creo Parametric for car engine design and simulation

- Best For: Precise 3D modeling and simulation of manufacturing processes.

- Why Choose Creo Parametric: It allows users to quickly simulate the entire manufacturing process, predicting potential errors and flaws.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Creo Parametric is ideal for professionals who require highly detailed simulations and precise 3D models.

3.4 Autodesk Inventor

Autodesk Inventor is a CAD software known for its stable performance, even when working on complex assemblies.

- Best For: Automotive component designs and mechanical design.

- Why Choose Autodesk Inventor: It includes a wide range of modeling options and powerful simulation tools, making it suitable for various automotive applications.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Inventor is a strong choice for technicians who need to work on heavy, complex, and large assemblies.

3.5 Rhino

Rhino (Rhinoceros) is a CAD modeling software developed by Robert McNeel & Associates.

- Best For: Creating and editing NURBS curves, surfaces, and solids.

- Why Choose Rhino: It is relatively easy to use and learn, allowing even inexperienced designers to create high-quality models optimized for 3D printing.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Rhino is versatile and can be effectively used for various automotive applications, making it a valuable tool for designers.

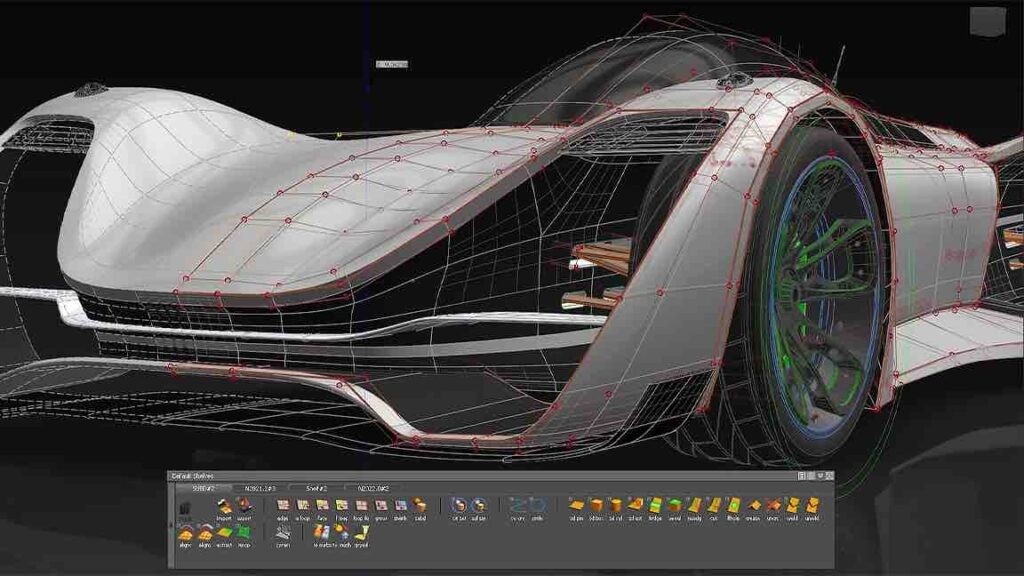

3.6 Autodesk Alias

Autodesk Alias is primarily used in automotive and industrial design to generate Class A surfaces.

Autodesk Alias Software

Autodesk Alias Software

- Best For: Designing Class A surfaces for automotive design.

- Why Choose Autodesk Alias: It is the go-to software for creating high-quality surfaces and is used by top automotive companies like Tesla and Aston Martin.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Mastering Alias can open doors to working on the most visually appealing and aerodynamic designs in the automotive industry.

3.7 Blender

Blender is a free and open-source 3D modeling application that supports modeling, texturing, rigging, animation, and lighting.

- Best For: Initial car model design and complex geometries.

- Why Choose Blender: It is free, capable of modeling complex geometries, and can significantly reduce design time.

- CAR-REMOTE-REPAIR.EDU.VN Insight: Blender is an excellent tool for quick design decisions and first-level car model design.

3.8 3Ds Max

Autodesk 3Ds Max is a popular choice for beginners and professionals alike for creating realistic car designs.

- Best For: Creating high-quality renderings and realistic car designs.

- Why Choose 3Ds Max: It teaches the fundamentals of surface modeling and supports Virtual Reality, making it easier to visualize models.

- CAR-REMOTE-REPAIR.EDU.VN Insight: 3Ds Max is ideal for design engineers who need to create immersive and interactive architectural visualizations.

3.9 OnShape

OnShape is a cloud-native product development platform that combines CAD, PDM, and enterprise analytics.

Designing an Open-Access F1 Car on the Cloud

Designing an Open-Access F1 Car on the Cloud

- Best For: Collaborative and secure creation of high-quality products.

- Why Choose OnShape: It modernizes the product design process and allows businesses to complete tasks faster and communicate more effectively.

- CAR-REMOTE-REPAIR.EDU.VN Insight: OnShape is a must-have tool for automotive manufacturers looking to streamline their product design process.

4. How Can CAD Software Improve The Efficiency Of Automotive Repair Processes?

CAD software improves efficiency by enabling precise design modifications, reducing prototyping time, and facilitating better communication and collaboration.

- Precise Design Modifications: Technicians can make accurate adjustments to designs, ensuring parts fit correctly.

- Reduced Prototyping Time: Digital prototypes allow for quick testing and modifications, reducing the need for physical prototypes.

- Better Communication: CAD models can be easily shared and reviewed, improving communication and collaboration among team members.

According to a 2021 study by McKinsey, companies that effectively integrate CAD and CAE tools into their workflows experience a 20-30% reduction in design and engineering costs.

5. What Role Does 3D Printing Play In Conjunction With CAD Software In Automotive Repair?

3D printing, combined with CAD software, allows for the creation of custom parts, rapid prototyping, and the production of obsolete or rare components, enhancing the flexibility and capabilities of automotive repair.

- Custom Parts: Technicians can design and print custom parts tailored to specific repair needs.

- Rapid Prototyping: 3D printing enables the quick creation of prototypes for testing and validation.

- Production of Obsolete Parts: 3D printing can be used to produce parts that are no longer available through traditional manufacturing methods.

BMW has successfully used 3D printing to produce custom parts for its classic cars, ensuring that owners can maintain their vehicles with authentic components, according to a 2020 case study by the company.

6. What Are The Advantages Of Using CAD Software For Designing Custom Automotive Parts?

The advantages include increased design precision, faster turnaround times, cost-effectiveness, and the ability to create complex geometries.

- Increased Design Precision: CAD software allows for highly accurate designs, ensuring parts meet exact specifications.

- Faster Turnaround Times: Digital designs can be quickly modified and produced using 3D printing, reducing lead times.

- Cost-Effectiveness: Creating custom parts with CAD and 3D printing can be more cost-effective than traditional manufacturing for low-volume production.

- Ability to Create Complex Geometries: CAD software can handle complex designs that would be difficult or impossible to create manually.

A 2022 report by Deloitte found that automotive companies using CAD and 3D printing for custom part design experienced a 25% reduction in manufacturing costs and a 30% decrease in lead times.

7. How Can Technicians Learn To Use CAD Software Effectively For Automotive Repair?

Technicians can learn through online courses, vocational training programs, and hands-on experience, with CAR-REMOTE-REPAIR.EDU.VN offering specialized training in automotive CAD applications.

- Online Courses: Platforms like Coursera and Udemy offer courses on CAD software for automotive applications.

- Vocational Training Programs: Technical schools and community colleges provide hands-on training in CAD software.

- Hands-On Experience: Practical experience with CAD software is essential for mastering its use in automotive repair.

- CAR-REMOTE-REPAIR.EDU.VN Training: Our specialized training programs provide in-depth knowledge and practical skills in automotive CAD applications.

According to a survey by the National Institute for Automotive Service Excellence (ASE) in 2023, technicians with formal training in CAD software are 40% more likely to be promoted to senior positions.

8. What Are The Emerging Trends In CAD Software For The Automotive Industry?

Emerging trends include cloud-based CAD, AI-driven design, and integration with virtual reality (VR) and augmented reality (AR) technologies, enhancing design and collaboration capabilities.

- Cloud-Based CAD: Allows for collaborative design and accessibility from anywhere.

- AI-Driven Design: AI algorithms can assist in generating and optimizing designs.

- VR/AR Integration: Enables immersive design reviews and virtual prototyping.

A 2024 report by Gartner predicts that by 2025, 50% of new CAD deployments in the automotive industry will be cloud-based, driven by the need for increased collaboration and flexibility.

9. How Does CAR-REMOTE-REPAIR.EDU.VN Integrate CAD Software Into Its Training Programs?

CAR-REMOTE-REPAIR.EDU.VN integrates CAD software into its training programs by offering hands-on courses, real-world project simulations, and expert instruction, ensuring technicians are proficient in using CAD for automotive repair.

- Hands-On Courses: Our courses provide practical experience with leading CAD software.

- Real-World Project Simulations: Technicians work on simulations of real-world automotive repair projects.

- Expert Instruction: Our instructors are experienced professionals in the automotive industry.

We offer specialized modules focusing on digital automotive modeling, automotive component designs, and automotive CAD modeling software, providing comprehensive training for aspiring and experienced technicians alike.

10. What Are Some Common Challenges Faced When Implementing CAD Software In Automotive Repair, And How Can They Be Addressed?

Common challenges include the initial cost, the learning curve, and integration with existing systems, which can be addressed through proper training, phased implementation, and choosing compatible software.

- Initial Cost: The cost of CAD software and hardware can be a barrier. Consider open-source or subscription-based options to reduce upfront costs.

- Learning Curve: Proper training and ongoing support can help technicians overcome the learning curve.

- Integration with Existing Systems: Choose CAD software that is compatible with your existing CAM and CAE systems.

A case study by the Automotive Industry Action Group (AIAG) in 2022 found that companies that invested in comprehensive training programs for CAD software implementation saw a 35% increase in productivity within the first year.

11. How Can CAD Software Help With Remote Automotive Repair Services?

CAD software facilitates remote repair services by enabling technicians to diagnose issues, design solutions, and guide on-site repairs using detailed 3D models and simulations.

- Remote Diagnostics: Technicians can analyze CAD models to identify potential issues remotely.

- Design Solutions: CAD software allows for the creation of custom repair solutions that can be shared with on-site technicians.

- Guided Repairs: Detailed 3D models and simulations can be used to guide on-site technicians through the repair process.

CAR-REMOTE-REPAIR.EDU.VN leverages CAD software to provide remote support and training to technicians, enhancing their ability to perform complex repairs efficiently and accurately.

12. What Types Of Automotive Components Can Be Designed And Repaired Using CAD Software?

CAD software can be used to design and repair a wide range of automotive components, including engine parts, body panels, interior components, and electrical systems.

- Engine Parts: Pistons, cylinder heads, and other engine components can be designed and optimized using CAD software.

- Body Panels: CAD software allows for the creation of precise body panel designs, ensuring a perfect fit.

- Interior Components: Dashboards, seats, and other interior components can be designed and customized using CAD software.

- Electrical Systems: Wiring harnesses and other electrical components can be designed and simulated using CAD software.

A study by the Center for Automotive Research (CAR) in 2023 found that the use of CAD software in the design and repair of automotive components has led to a 15% reduction in warranty claims due to improved precision and quality.

13. What Is The Role Of CAD Software In Automotive Restorations?

CAD software is invaluable in automotive restorations, allowing technicians to recreate original parts, reverse engineer damaged components, and ensure accurate reproductions.

- Recreating Original Parts: CAD software can be used to create digital models of original parts that are no longer available.

- Reverse Engineering: Damaged components can be scanned and reverse engineered using CAD software to create replacement parts.

- Accurate Reproductions: CAD software ensures that reproductions are accurate and meet the original specifications.

Classic car restoration shops are increasingly using CAD software to preserve the authenticity and value of vintage vehicles.

14. What Is The Difference Between 2D And 3D CAD Software, And Which Is More Suitable For Automotive Repair?

2D CAD software is used for creating two-dimensional drawings, while 3D CAD software is used for creating three-dimensional models. 3D CAD software is generally more suitable for automotive repair due to its ability to provide a more realistic and detailed representation of components.

- 2D CAD Software: Suitable for basic drawings and schematics.

- 3D CAD Software: Provides a more realistic and detailed representation of components, allowing for better visualization and analysis.

While 2D CAD software can be useful for creating wiring diagrams and schematics, 3D CAD software is essential for designing and repairing complex automotive components.

15. How Can Automotive Businesses Justify The Investment In CAD Software And Training?

Automotive businesses can justify the investment by highlighting the benefits of increased efficiency, reduced costs, improved quality, and the ability to offer advanced services.

- Increased Efficiency: CAD software streamlines the design and repair process, reducing turnaround times.

- Reduced Costs: Digital prototyping and custom part creation can reduce manufacturing and prototyping costs.

- Improved Quality: CAD software ensures precise designs and accurate reproductions, improving the quality of repairs.

- Advanced Services: Offering CAD-based design and repair services can attract new customers and increase revenue.

A return on investment (ROI) analysis can demonstrate the financial benefits of investing in CAD software and training, making it easier to justify the expense.

16. What Are Some Best Practices For Managing CAD Files And Designs In An Automotive Repair Shop?

Best practices include establishing a clear file naming convention, using a version control system, regularly backing up files, and implementing access controls to protect sensitive data.

- Clear File Naming Convention: Use a consistent naming convention to easily identify and locate CAD files.

- Version Control System: Implement a version control system to track changes and prevent data loss.

- Regular Backups: Regularly back up CAD files to protect against data loss due to hardware failure or other issues.

- Access Controls: Implement access controls to limit access to sensitive data and prevent unauthorized modifications.

Implementing these best practices can help ensure that CAD files are properly managed and protected.

17. How Can CAD Software Assist In Diagnosing Automotive Problems?

CAD software assists in diagnosing automotive problems by providing detailed 3D models of components, allowing technicians to visualize the internal workings of the vehicle and identify potential issues.

- Detailed 3D Models: Technicians can use CAD models to visualize the internal workings of the vehicle and identify potential issues.

- Simulation Capabilities: CAD software allows for simulating various operating conditions to identify problems that may not be apparent during a visual inspection.

- Remote Diagnostics: CAD models can be shared remotely, allowing technicians to collaborate on diagnosing complex issues.

By providing a detailed and accurate representation of the vehicle, CAD software can significantly improve the accuracy and efficiency of the diagnostic process.

18. What Are The Legal Considerations When Using CAD Software For Automotive Design And Repair?

Legal considerations include intellectual property rights, licensing agreements, and compliance with industry standards.

- Intellectual Property Rights: Ensure that you have the right to use any CAD models or designs that you create or modify.

- Licensing Agreements: Comply with the terms of the licensing agreement for your CAD software.

- Industry Standards: Ensure that your designs and repairs comply with relevant industry standards and regulations.

Consulting with a legal professional can help ensure that you are in compliance with all applicable laws and regulations.

19. How Can CAD Software Be Used To Create Custom Modifications For Vehicles?

CAD software can be used to create custom modifications by allowing technicians to design and test new components, ensuring they fit properly and function as intended.

- Design and Test New Components: Technicians can use CAD software to design and test new components, such as body kits, spoilers, and custom engine parts.

- Ensure Proper Fit: CAD software allows for simulating the installation of new components to ensure they fit properly and do not interfere with other parts of the vehicle.

- Functional Testing: CAD software can be used to simulate the performance of new components to ensure they function as intended.

By providing the tools to design and test custom modifications, CAD software opens up a world of possibilities for vehicle customization.

20. How Can CAR-REMOTE-REPAIR.EDU.VN Help Automotive Technicians Stay Up-To-Date With The Latest CAD Software Technologies?

CAR-REMOTE-REPAIR.EDU.VN helps technicians stay up-to-date by offering continuous education, advanced training modules, and industry partnerships, ensuring they are proficient in the latest CAD software technologies.

- Continuous Education: We offer ongoing training and education to ensure that technicians are always up-to-date with the latest technologies.

- Advanced Training Modules: Our advanced training modules focus on the latest features and capabilities of leading CAD software.

- Industry Partnerships: We partner with leading CAD software vendors and automotive manufacturers to provide technicians with access to the latest tools and technologies.

Our comprehensive training programs are designed to equip technicians with the skills and knowledge they need to succeed in the rapidly evolving automotive industry.

Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States.

Whatsapp: +1 (641) 206-8880.

Website: CAR-REMOTE-REPAIR.EDU.VN.

Ready to elevate your automotive repair skills? Visit CAR-REMOTE-REPAIR.EDU.VN today to explore our specialized training programs and discover how CAD software can revolutionize your approach to automotive repair in the USA. Unlock your potential and become a leader in the future of automotive technology.

FAQ About CAD Software For Cars

1. What is the primary benefit of using CAD software in automotive design?

The primary benefit is enhanced precision and efficiency in designing and modifying vehicle components, reducing errors and prototyping time.

2. Which CAD software is best for designing Class A surfaces in automotive design?

Autodesk Alias is widely regarded as the best CAD software for designing Class A surfaces due to its specialized tools and capabilities.

3. Can beginners learn to use CAD software for automotive repair?

Yes, software like Autodesk 3Ds Max is excellent for beginners, teaching the fundamentals of surface modeling and creating realistic car designs.

4. Is cloud-based CAD software a good option for automotive repair shops?

Yes, cloud-based CAD software like OnShape offers benefits such as collaborative design, accessibility from anywhere, and integrated data management.

5. How does 3D printing enhance the use of CAD software in automotive repair?

3D printing allows for the creation of custom parts, rapid prototyping, and the production of obsolete components, enhancing the flexibility and capabilities of automotive repair.

6. What are the key features to look for when choosing CAD software for automotive applications?

Key features include 3D modeling, simulation capabilities, compatibility with various file formats, a user-friendly interface, and integration with other systems like CAM and CAE.

7. How can CAD software help with remote automotive repair services?

CAD software enables technicians to diagnose issues remotely, design custom repair solutions, and guide on-site technicians through the repair process using detailed 3D models.

8. What types of training are available for learning CAD software for automotive repair?

Training options include online courses, vocational training programs, hands-on experience, and specialized training programs offered by institutions like CAR-REMOTE-REPAIR.EDU.VN.

9. How can automotive businesses justify the investment in CAD software and training?

Businesses can justify the investment by highlighting increased efficiency, reduced costs, improved quality, and the ability to offer advanced services, resulting in a positive return on investment.

10. What emerging trends in CAD software should automotive technicians be aware of?

Emerging trends include cloud-based CAD, AI-driven design, and integration with virtual reality (VR) and augmented reality (AR) technologies, enhancing design and collaboration capabilities.