Care Label Printing Software is a specialized tool that enables businesses, especially those in the automotive repair industry, to design and print durable, informative care labels for various auto parts and equipment, and it is crucial for clear communication and compliance. CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training to help you master this essential skill. Our courses cover everything from software selection to label design best practices, ensuring you can create labels that meet industry standards and enhance your service quality. These training programs will also help you to optimize your use of diagnostic tools, enhancing your skills in remote auto repair and diagnostics. According to a recent study by the Automotive Management Institute (AMI), technicians with up-to-date training in software applications like care label printing software demonstrate a 25% increase in efficiency and accuracy.

Contents

- 1. What is Care Label Printing Software?

- 1.1 Key Features of Care Label Printing Software

- 1.2 Benefits of Using Care Label Printing Software

- 1.3 How Care Label Printing Software Works

- 2. Who Benefits from Care Label Printing Software?

- 2.1 Automotive Technicians

- 2.2 Automotive Repair Shops

- 2.3 Auto Parts Manufacturers

- 2.4 Automotive Service Advisors

- 2.5 Automotive Educators

- 3. What are the Key Features to Look for in Care Label Printing Software?

- 3.1 User-Friendly Interface

- 3.2 Customizable Templates

- 3.3 Barcode and QR Code Generation

- 3.4 Database Integration

- 3.5 Compliance Features

- 3.6 Printing Options

- 3.7 Integration with Other Systems

- 4. How to Choose the Right Care Label Printing Software for Your Needs?

- 4.1 Assess Your Specific Needs

- 4.2 Evaluate Software Features

- 4.3 Consider Ease of Use

- 4.4 Check Compatibility

- 4.5 Read Reviews and Testimonials

- 4.6 Request a Demo or Trial

- 4.7 Consider Scalability

- 4.8 Evaluate Customer Support

- 4.9 Consider Cloud-Based vs. On-Premise Solutions

- 4.10 Review Pricing and Licensing Options

- 5. How to Use Care Label Printing Software Effectively?

- 5.1 Design Labels with Clarity and Compliance

- 5.2 Manage Data Efficiently

- 5.3 Optimize Printing Processes

- 5.4 Train Your Staff

- 5.5 Maintain Your Software

- 5.6 Integrate with Other Systems

- 6. Common Mistakes to Avoid When Using Care Label Printing Software

- 6.1 Neglecting Software Training

- 6.2 Ignoring Compliance Standards

- 6.3 Overlooking Label Design Best Practices

- 6.4 Failing to Calibrate Printers

- 6.5 Using the Wrong Label Stock

- 6.6 Neglecting Data Validation

- 6.7 Ignoring Software Updates

- 7. How Does Care Label Printing Software Help with Compliance?

- 7.1 Ensuring Accurate and Complete Information

- 7.2 Meeting Formatting Requirements

- 7.3 Automating Compliance Checks

- 7.4 Reducing the Risk of Errors

- 7.5 Maintaining an Audit Trail

- 8. What are the Latest Trends in Care Label Printing Software?

- 8.1 Cloud-Based Solutions

- 8.2 Mobile Printing

- 8.3 Integration with IoT Devices

- 8.4 Enhanced Data Management

- 8.5 Artificial Intelligence (AI)

- 8.6 Sustainability

- 9. Case Studies: How Businesses are Using Care Label Printing Software

- 9.1 Case Study 1: Automotive Repair Shop Streamlines Inventory Management

- 9.2 Case Study 2: Auto Parts Manufacturer Ensures Compliance

- 9.3 Case Study 3: Automotive Service Advisor Improves Customer Communication

- 10. Frequently Asked Questions (FAQs) About Care Label Printing Software

- 10.1 What is care label printing software?

- 10.2 Who benefits from using care label printing software?

- 10.3 What are the key features to look for in care label printing software?

- 10.4 How does care label printing software help with compliance?

- 10.5 What are the latest trends in care label printing software?

- 10.6 How do I choose the right care label printing software for my needs?

- 10.7 What are some common mistakes to avoid when using care label printing software?

- 10.8 Can care label printing software integrate with my existing systems?

- 10.9 How much does care label printing software cost?

- 10.10 Where can I find more information about care label printing software?

1. What is Care Label Printing Software?

Care label printing software is a specialized application designed to create and print durable, informative labels for various products, especially in industries like automotive repair and maintenance. It allows technicians and shop owners to design labels that include important information such as part numbers, manufacturing dates, safety warnings, and maintenance instructions.

1.1 Key Features of Care Label Printing Software

Care label printing software typically includes a range of features tailored to the specific needs of label creation and management:

- Customizable Templates: Pre-designed templates that can be easily modified to fit different label sizes and content requirements.

- Barcode Generation: Tools to create various types of barcodes for efficient tracking and inventory management.

- Database Integration: Ability to connect to databases for automatic population of label data, reducing manual entry errors.

- Compliance Standards: Built-in support for industry-specific regulations and standards, ensuring labels meet legal requirements.

- Image and Symbol Libraries: Extensive libraries of symbols and images relevant to automotive maintenance and safety.

- Variable Data Printing: Capability to print labels with sequential numbers, serial numbers, or other variable data.

- User-Friendly Interface: Intuitive design for ease of use, minimizing the learning curve for new users.

- Print Preview: Feature to preview labels before printing, ensuring accuracy and minimizing waste.

- Material Compatibility: Options to optimize printing for different label materials, such as thermal transfer or direct thermal labels.

- Connectivity Options: Support for various printer connections, including USB, Ethernet, and wireless.

1.2 Benefits of Using Care Label Printing Software

Using care label printing software offers several advantages for automotive repair businesses:

- Accuracy: Minimizes errors in label information, ensuring correct and consistent data.

- Efficiency: Streamlines the label creation and printing process, saving time and resources.

- Compliance: Helps meet industry standards and regulations, reducing the risk of legal issues.

- Professionalism: Enhances the appearance of products with professionally designed labels.

- Inventory Management: Facilitates efficient tracking and management of parts and equipment.

- Safety: Clearly communicates safety warnings and instructions, reducing the risk of accidents.

- Cost Savings: Reduces waste and minimizes the need for manual label creation, saving money on supplies and labor.

- Customization: Allows for the creation of labels tailored to specific products or customer needs.

- Brand Enhancement: Provides an opportunity to reinforce brand identity with custom logos and designs.

- Traceability: Enables easy tracking of parts and equipment throughout their lifecycle.

1.3 How Care Label Printing Software Works

Care label printing software typically operates through the following steps:

- Design: The user selects a template or creates a custom label design using the software’s design tools.

- Data Entry: The user enters or imports the necessary data, such as part numbers, descriptions, and safety information.

- Formatting: The user formats the label, adjusting font sizes, colors, and layout to ensure readability and visual appeal.

- Preview: The user previews the label to check for errors and make any necessary adjustments.

- Printing: The user selects the appropriate printer and label material and prints the labels.

- Application: The printed labels are applied to the relevant parts or equipment.

2. Who Benefits from Care Label Printing Software?

Care label printing software is a valuable tool for a variety of professionals and businesses within the automotive industry. Its ability to streamline labeling processes, ensure accuracy, and maintain compliance makes it an essential asset for anyone involved in vehicle maintenance, repair, and parts management.

2.1 Automotive Technicians

Automotive technicians can use care label printing software to create labels for various components they service or replace. This includes:

- Identifying Replacement Parts: Clearly labeling new parts with part numbers and installation dates to ensure proper tracking and warranty management.

- Marking Serviced Components: Attaching labels to serviced components with the date of service, technician ID, and next service due date.

- Providing Safety Information: Labeling parts with safety warnings or specific handling instructions to prevent accidents and ensure proper use.

- Organizing Workspace: Using labels to organize tools, equipment, and supplies in the workshop, improving efficiency and reducing clutter.

2.2 Automotive Repair Shops

Automotive repair shops benefit from care label printing software in several ways:

- Inventory Management: Labeling parts and supplies in the inventory with barcodes and part numbers for easy tracking and stock management.

- Customer Service: Providing customers with detailed information about the services performed and parts replaced, enhancing transparency and trust.

- Compliance: Ensuring that all labels meet industry standards and regulations, reducing the risk of legal issues and fines.

- Branding: Customizing labels with the shop’s logo and contact information to reinforce brand identity and promote repeat business.

- Efficiency: Streamlining the labeling process, saving time and resources, and allowing technicians to focus on repairs.

2.3 Auto Parts Manufacturers

Auto parts manufacturers rely on care label printing software for:

- Product Identification: Labeling parts with unique identifiers, manufacturing dates, and other relevant information for traceability and quality control.

- Compliance: Meeting industry standards and regulations for labeling, ensuring that products are safe and properly identified.

- Inventory Management: Using barcodes and QR codes on labels to track parts throughout the manufacturing and distribution process.

- Customer Communication: Providing clear and accurate information to customers, including installation instructions, safety warnings, and warranty details.

- Brand Protection: Protecting against counterfeiting by using tamper-evident labels and unique identifiers.

2.4 Automotive Service Advisors

Automotive service advisors can use care label printing software to:

- Enhance Customer Communication: Generate labels with service details to attach to invoices and customer records, ensuring clear and accurate information.

- Improve Transparency: Provide customers with detailed labels explaining the work performed, parts replaced, and any recommendations for future service.

- Build Trust: Demonstrate professionalism and attention to detail by providing well-labeled and organized service records.

- Streamline Service Process: Quickly generate labels for service orders, parts requests, and other documentation, improving efficiency and reducing errors.

2.5 Automotive Educators

Automotive educators can leverage care label printing software to:

- Train Students: Teach students how to properly label parts and components, emphasizing the importance of accuracy and compliance.

- Create Educational Materials: Develop instructional labels and diagrams for use in the classroom and workshop.

- Simulate Real-World Scenarios: Provide students with hands-on experience in creating and applying labels in a realistic automotive repair setting.

- Prepare Students for Certification: Ensure that students are familiar with industry standards and best practices for labeling, preparing them for certification exams.

3. What are the Key Features to Look for in Care Label Printing Software?

When selecting care label printing software, it’s important to consider the features that will best meet your specific needs. The right software can streamline your labeling process, improve accuracy, and ensure compliance with industry standards.

3.1 User-Friendly Interface

A user-friendly interface is crucial for ease of use and efficiency. Look for software with:

- Intuitive Design: A clear and straightforward layout that is easy to navigate.

- Drag-and-Drop Functionality: Allows you to easily add and position elements on the label.

- Customizable Workspace: The ability to customize the interface to suit your preferences and workflow.

- Help Resources: Built-in help documentation, tutorials, and support resources to assist you when needed.

3.2 Customizable Templates

Customizable templates can save you time and effort by providing pre-designed layouts that you can easily modify. Look for software with:

- Variety of Templates: A wide selection of templates for different label sizes, shapes, and purposes.

- Easy Customization: The ability to easily change fonts, colors, and images to match your branding.

- Template Creation: The option to create your own templates from scratch and save them for future use.

3.3 Barcode and QR Code Generation

Barcode and QR code generation is essential for tracking and inventory management. Look for software with:

- Support for Multiple Barcode Types: The ability to generate a variety of barcode types, including Code 39, Code 128, and QR codes.

- Customizable Barcode Settings: The option to adjust barcode size, density, and error correction level.

- Easy Barcode Integration: The ability to easily add barcodes to your labels and link them to data fields.

3.4 Database Integration

Database integration allows you to automatically populate labels with data from your existing systems. Look for software with:

- Compatibility with Multiple Databases: The ability to connect to various databases, such as Excel, Access, SQL Server, and Oracle.

- Real-Time Data Updates: The option to automatically update label data when changes are made in the database.

- Easy Data Mapping: A simple way to map data fields from the database to the corresponding fields on the label.

3.5 Compliance Features

Compliance features help you meet industry standards and regulations. Look for software with:

- Pre-Built Compliance Templates: Templates that are pre-configured to meet specific compliance requirements.

- Compliance Validation: Tools to validate your labels and ensure that they meet the necessary standards.

- Audit Trail: A record of all changes made to the labels, providing traceability and accountability.

3.6 Printing Options

Printing options should be flexible and allow you to print labels efficiently. Look for software with:

- Support for Multiple Printers: The ability to work with a variety of printers, including thermal transfer, direct thermal, and laser printers.

- Print Preview: A preview feature that allows you to see how the label will look before printing.

- Batch Printing: The option to print multiple labels at once, saving time and effort.

- Print Queuing: The ability to queue up multiple print jobs and manage them efficiently.

3.7 Integration with Other Systems

Integration with other systems can streamline your workflow and improve efficiency. Look for software with:

- API Support: An API that allows you to integrate the software with other applications, such as ERP, WMS, and CRM systems.

- SDK Availability: A software development kit (SDK) that allows you to create custom integrations and extensions.

4. How to Choose the Right Care Label Printing Software for Your Needs?

Choosing the right care label printing software is a critical decision that can significantly impact your operational efficiency, compliance, and overall productivity. To make an informed choice, consider these key factors:

4.1 Assess Your Specific Needs

Start by evaluating your unique requirements. Consider the following questions:

- What types of labels do you need to print? (e.g., care labels, compliance labels, inventory labels)

- What information needs to be included on the labels? (e.g., part numbers, sizes, materials, care instructions)

- How many labels do you print on a daily or weekly basis? (This will help determine the software’s scalability requirements.)

- Do you need to comply with any industry-specific regulations? (e.g., automotive standards, safety regulations)

- What is your budget for the software? (Consider both upfront costs and ongoing maintenance fees.)

4.2 Evaluate Software Features

Once you have a clear understanding of your needs, evaluate the features offered by different software options. Key features to consider include:

- Label Design Tools: Look for an intuitive interface with drag-and-drop functionality, customizable templates, and support for various fonts, colors, and graphics.

- Barcode and QR Code Generation: Ensure the software supports the types of barcodes and QR codes you need to use.

- Database Integration: If you need to print labels with variable data, choose software that can connect to your existing databases (e.g., Excel, SQL Server).

- Printing Options: Verify that the software is compatible with your printers and supports features like batch printing and print preview.

- Compliance Features: If you need to comply with industry-specific regulations, look for software with pre-built compliance templates and validation tools.

- Integration with Other Systems: Consider whether the software needs to integrate with other systems, such as ERP, WMS, or CRM.

4.3 Consider Ease of Use

The software should be easy to learn and use, even for employees with limited technical skills. Look for a user-friendly interface, comprehensive documentation, and responsive customer support.

4.4 Check Compatibility

Ensure that the software is compatible with your operating system, printers, and other hardware.

4.5 Read Reviews and Testimonials

Research online reviews and testimonials from other users to get an idea of the software’s strengths and weaknesses.

4.6 Request a Demo or Trial

Most software vendors offer a free demo or trial period. Take advantage of this opportunity to test the software and see if it meets your needs.

4.7 Consider Scalability

Choose software that can grow with your business. As your labeling needs evolve, you should be able to easily upgrade the software or add new features.

4.8 Evaluate Customer Support

Good customer support is essential, especially when you’re just getting started with the software. Look for vendors that offer responsive support via phone, email, or online chat.

4.9 Consider Cloud-Based vs. On-Premise Solutions

Decide whether you prefer a cloud-based or on-premise solution. Cloud-based solutions offer greater flexibility and accessibility, while on-premise solutions provide more control over your data.

4.10 Review Pricing and Licensing Options

Understand the pricing and licensing options offered by the vendor. Some software is sold as a one-time purchase, while others are subscription-based.

5. How to Use Care Label Printing Software Effectively?

Using care label printing software effectively involves more than just installing the program and printing labels. It requires a strategic approach to design, data management, and printing processes. Here’s a comprehensive guide to help you maximize the benefits of your care label printing software.

5.1 Design Labels with Clarity and Compliance

- Choose the Right Template: Start with a template that matches the size, shape, and layout requirements of your labels. Most software offers a variety of pre-designed templates that can be customized.

- Use Clear and Concise Language: Ensure that all text on the label is easy to read and understand. Use a clear font and appropriate font size.

- Include Essential Information: Include all necessary information, such as part numbers, sizes, materials, care instructions, and compliance symbols.

- Incorporate Visual Elements: Use images, symbols, and logos to enhance the visual appeal of the label and convey information more effectively.

- Adhere to Compliance Standards: Ensure that your labels comply with all relevant industry standards and regulations.

5.2 Manage Data Efficiently

- Connect to a Database: If you need to print labels with variable data, connect your software to a database containing the relevant information. This will automate the data entry process and reduce errors.

- Use Data Validation: Implement data validation rules to ensure that the data entered into the label is accurate and consistent.

- Automate Data Entry: Use features like sequential numbering and barcode scanning to automate data entry and minimize manual input.

- Maintain Data Integrity: Regularly back up your data and implement security measures to protect against data loss or corruption.

5.3 Optimize Printing Processes

- Calibrate Your Printer: Ensure that your printer is properly calibrated to produce high-quality labels.

- Use the Right Label Stock: Choose label stock that is compatible with your printer and suitable for the intended application.

- Test Print Before Production: Always test print a few labels before printing a large batch to ensure that everything looks correct.

- Use Batch Printing: Take advantage of batch printing features to print multiple labels at once, saving time and improving efficiency.

- Monitor Print Quality: Regularly check the print quality of your labels to ensure that they are clear and legible.

5.4 Train Your Staff

- Provide Comprehensive Training: Ensure that all staff members who will be using the software receive comprehensive training on its features and functions.

- Create Standard Operating Procedures (SOPs): Develop SOPs for label design, data management, and printing processes to ensure consistency and compliance.

- Offer Ongoing Support: Provide ongoing support and training to help staff members stay up-to-date with the latest software features and best practices.

5.5 Maintain Your Software

- Install Updates Regularly: Install software updates regularly to ensure that you have the latest features, bug fixes, and security patches.

- Perform Regular Maintenance: Perform regular maintenance tasks, such as cleaning your printer and checking your database for errors.

- Monitor Performance: Monitor the performance of your software and hardware to identify and address any issues before they become major problems.

5.6 Integrate with Other Systems

- Connect to ERP, WMS, and CRM Systems: Integrate your care label printing software with other business systems to streamline data flow and improve efficiency.

- Use APIs and SDKs: Take advantage of APIs and SDKs to create custom integrations and extensions that meet your specific needs.

6. Common Mistakes to Avoid When Using Care Label Printing Software

Using care label printing software can greatly enhance the efficiency and accuracy of your labeling processes. However, like any tool, it’s easy to make mistakes that can lead to errors, waste, and compliance issues. Here are some common pitfalls to avoid:

6.1 Neglecting Software Training

One of the most common mistakes is failing to properly train staff on how to use the software. This can result in:

- Incorrect Label Designs: Users may create labels that are missing crucial information or are formatted incorrectly.

- Data Entry Errors: Untrained users may make mistakes when entering data, leading to inaccurate labels.

- Inefficient Workflows: Users may not know how to use the software’s advanced features, resulting in slower and less efficient processes.

Solution: Provide comprehensive training to all staff members who will be using the software. Cover all aspects of label design, data management, and printing.

6.2 Ignoring Compliance Standards

Many industries have specific labeling requirements that must be met. Ignoring these standards can result in:

- Fines and Penalties: Non-compliant labels can lead to fines and penalties from regulatory agencies.

- Product Recalls: Incorrectly labeled products may need to be recalled, which can be costly and damaging to your reputation.

- Legal Issues: Non-compliant labels can expose your company to legal liabilities.

Solution: Familiarize yourself with the labeling requirements for your industry. Use software features like compliance templates and validation tools to ensure that your labels meet the necessary standards.

6.3 Overlooking Label Design Best Practices

Poor label design can make it difficult for customers to read and understand the information on the label. This can lead to:

- Customer Confusion: Customers may not be able to understand the product information, leading to dissatisfaction and returns.

- Safety Issues: If safety warnings are not clearly displayed, customers may misuse the product and get injured.

- Inefficient Inventory Management: Poorly designed labels can make it difficult to track and manage inventory.

Solution: Follow label design best practices, such as using clear fonts, appropriate font sizes, and high-contrast colors. Include essential information and use visual elements to enhance readability.

6.4 Failing to Calibrate Printers

If your printer is not properly calibrated, the labels you print may be distorted, blurry, or have inaccurate colors. This can make it difficult to read the labels and may even cause barcodes to be unscannable.

Solution: Calibrate your printer regularly to ensure that it is printing labels accurately. Follow the manufacturer’s instructions for calibration.

6.5 Using the Wrong Label Stock

Using the wrong label stock can result in labels that are difficult to apply, don’t adhere properly, or fade over time. This can lead to:

- Label Damage: Labels may peel off, tear, or become illegible.

- Product Damage: Labels that don’t adhere properly can damage the product they are attached to.

- Wasted Resources: You may waste time and money reprinting labels that fail.

Solution: Choose label stock that is compatible with your printer and suitable for the intended application. Consider factors like adhesive type, material, and durability.

6.6 Neglecting Data Validation

Failing to validate data before printing labels can result in inaccurate labels that contain errors. This can lead to:

- Inventory Discrepancies: Incorrectly labeled products can cause discrepancies in your inventory records.

- Shipping Errors: Mislabeling products can result in shipping errors and delays.

- Customer Dissatisfaction: Customers may receive the wrong products or products with incorrect information.

Solution: Use data validation features to ensure that the data entered into the label is accurate and consistent. Implement rules to check for errors and prevent invalid data from being printed.

6.7 Ignoring Software Updates

Software updates often include bug fixes, security patches, and new features that can improve the performance and security of your labeling system. Ignoring these updates can leave you vulnerable to:

- Security Vulnerabilities: Outdated software may be vulnerable to security exploits that can compromise your data.

- Performance Issues: Old software may run slowly or crash frequently.

- Compatibility Problems: Outdated software may not be compatible with new printers or operating systems.

Solution: Install software updates regularly to ensure that you have the latest features, bug fixes, and security patches.

7. How Does Care Label Printing Software Help with Compliance?

Care label printing software is an indispensable tool for businesses striving to maintain compliance with industry-specific regulations and standards. These regulations, which vary across industries and regions, dictate the information that must be included on product labels, as well as the format and presentation of that information.

7.1 Ensuring Accurate and Complete Information

Care label printing software helps ensure that labels contain all the necessary information required by compliance standards. This includes:

- Product Identification: Accurate product names, part numbers, and model numbers.

- Care Instructions: Clear and concise instructions on how to care for the product, including washing, drying, and ironing guidelines.

- Safety Warnings: Prominent warnings about potential hazards associated with the product.

- Compliance Symbols: Standardized symbols that indicate compliance with specific regulations, such as the Underwriters Laboratories (UL) mark or the CE mark.

- Manufacturer Information: Name and address of the manufacturer or distributor.

- Country of Origin: The country where the product was manufactured or assembled.

7.2 Meeting Formatting Requirements

Compliance standards often specify the format and presentation of information on labels. Care label printing software helps businesses meet these requirements by providing tools to:

- Control Font Sizes and Styles: Ensure that text is legible and meets minimum font size requirements.

- Position Elements Accurately: Place required elements in specific locations on the label.

- Use Standardized Symbols: Incorporate standardized compliance symbols in the correct size and format.

- Create Barcodes and QR Codes: Generate barcodes and QR codes that meet industry standards.

7.3 Automating Compliance Checks

Some care label printing software includes features that automate compliance checks. These features can:

- Validate Data: Check that all required data fields are populated and contain valid information.

- Verify Formatting: Ensure that labels meet formatting requirements, such as font sizes and element placement.

- Generate Compliance Reports: Create reports that document compliance with specific regulations.

7.4 Reducing the Risk of Errors

Manual label creation processes are prone to errors, which can lead to compliance violations. Care label printing software reduces the risk of errors by:

- Automating Data Entry: Connecting to databases to automatically populate labels with accurate data.

- Using Pre-Designed Templates: Providing pre-designed templates that incorporate compliance requirements.

- Implementing Data Validation Rules: Preventing invalid data from being entered on labels.

7.5 Maintaining an Audit Trail

In the event of a compliance audit, businesses must be able to demonstrate that their labels meet all applicable requirements. Care label printing software helps maintain an audit trail by:

- Tracking Label Revisions: Recording all changes made to label designs and data.

- Storing Label History: Maintaining a history of all labels that have been printed.

- Generating Audit Reports: Creating reports that document the label creation process and demonstrate compliance with regulations.

8. What are the Latest Trends in Care Label Printing Software?

The field of care label printing software is continually evolving, driven by advancements in technology, changing industry needs, and increasing demands for efficiency and compliance. Staying abreast of the latest trends can help businesses optimize their labeling processes and gain a competitive edge.

8.1 Cloud-Based Solutions

Cloud-based care label printing software is gaining popularity due to its numerous benefits:

- Accessibility: Access your labeling system from anywhere with an internet connection.

- Scalability: Easily scale your system up or down to meet changing business needs.

- Cost Savings: Reduce IT infrastructure costs and eliminate the need for on-premise servers.

- Automatic Updates: Benefit from automatic software updates and maintenance.

- Collaboration: Enable collaboration among multiple users and locations.

8.2 Mobile Printing

Mobile printing solutions are enabling businesses to print labels on the go, using smartphones, tablets, and portable printers. This is particularly useful for:

- Field Service Technicians: Print labels at the point of service, eliminating the need to return to the office.

- Warehouse Workers: Print labels directly in the warehouse, improving efficiency and reducing errors.

- Retailers: Print labels on the sales floor, enabling real-time price changes and promotions.

8.3 Integration with IoT Devices

The Internet of Things (IoT) is transforming the way businesses operate, and care label printing is no exception. Integration with IoT devices enables:

- Automated Label Triggering: Automatically trigger label printing based on data from sensors and other IoT devices.

- Real-Time Data Updates: Update label data in real-time, based on information from IoT devices.

- Predictive Maintenance: Use IoT data to predict when labels need to be replaced or updated.

8.4 Enhanced Data Management

Care label printing software is becoming more sophisticated in its ability to manage and process data. This includes:

- Advanced Data Validation: Implement complex data validation rules to ensure accuracy and compliance.

- Data Analytics: Analyze label data to identify trends, optimize processes, and improve decision-making.

- Integration with Big Data Platforms: Integrate with big data platforms to process and analyze large volumes of label data.

8.5 Artificial Intelligence (AI)

Artificial intelligence (AI) is beginning to play a role in care label printing software, enabling:

- Automated Label Design: Use AI to automatically generate label designs based on product information and compliance requirements.

- Predictive Printing: Use AI to predict when labels will need to be printed, based on historical data and current trends.

- Quality Control: Use AI to automatically inspect printed labels and identify defects.

8.6 Sustainability

Sustainability is becoming an increasingly important consideration for businesses, and care label printing is no exception. This includes:

- Eco-Friendly Label Materials: Use label materials that are made from recycled content or are biodegradable.

- Reduced Waste: Optimize label designs to minimize waste and reduce the amount of material used.

- Energy-Efficient Printing: Use energy-efficient printers and printing processes.

9. Case Studies: How Businesses are Using Care Label Printing Software

To illustrate the practical benefits of care label printing software, let’s examine a few case studies of businesses that have successfully implemented these solutions.

9.1 Case Study 1: Automotive Repair Shop Streamlines Inventory Management

Challenge: A busy automotive repair shop struggled with disorganized inventory, leading to wasted time and lost revenue. Technicians often spent valuable time searching for parts, and the shop had difficulty tracking inventory levels accurately.

Solution: The shop implemented care label printing software with barcode generation capabilities. They labeled all parts with barcodes containing part numbers, descriptions, and storage locations.

Results:

- Improved Inventory Accuracy: The shop reduced inventory discrepancies by 90%.

- Reduced Search Time: Technicians were able to find parts 50% faster, saving valuable time and increasing productivity.

- Better Inventory Control: The shop was able to track inventory levels in real-time, preventing stockouts and overstocking.

- Increased Revenue: By improving efficiency and reducing waste, the shop increased its revenue by 15%.

9.2 Case Study 2: Auto Parts Manufacturer Ensures Compliance

Challenge: An auto parts manufacturer needed to comply with complex industry regulations for labeling its products. The company was using manual labeling processes, which were prone to errors and difficult to manage.

Solution: The manufacturer implemented care label printing software with compliance features. The software included pre-built compliance templates and data validation tools to ensure that labels met all regulatory requirements.

Results:

- Reduced Compliance Violations: The company eliminated compliance violations and avoided costly fines.

- Improved Label Accuracy: The software reduced errors in label data, ensuring that products were labeled correctly.

- Streamlined Labeling Process: The software automated the labeling process, saving time and resources.

- Enhanced Reputation: By ensuring compliance and accuracy, the company enhanced its reputation and gained a competitive advantage.

9.3 Case Study 3: Automotive Service Advisor Improves Customer Communication

Challenge: An automotive service advisor wanted to improve communication with customers and provide them with more detailed information about the services performed on their vehicles.

Solution: The service advisor implemented care label printing software to generate labels with service details. The labels included the date of service, the technician who performed the work, a description of the services performed, and any recommendations for future service.

Results:

- Improved Customer Satisfaction: Customers were more satisfied with the service they received because they had a clear understanding of the work that was performed.

- Increased Trust: Customers trusted the service advisor more because they were provided with detailed and accurate information.

- Better Record Keeping: The labels provided a clear and organized record of the services performed on each vehicle.

- Increased Repeat Business: By improving customer satisfaction and trust, the service advisor increased repeat business.

10. Frequently Asked Questions (FAQs) About Care Label Printing Software

Here are some frequently asked questions about care label printing software to help you better understand its capabilities and benefits:

10.1 What is care label printing software?

Care label printing software is a specialized application designed to create and print durable, informative labels for various products, especially in industries like automotive repair and maintenance. It allows users to design labels that include important information such as part numbers, manufacturing dates, safety warnings, and maintenance instructions.

10.2 Who benefits from using care label printing software?

Automotive technicians, repair shops, auto parts manufacturers, service advisors, and educators can benefit from using care label printing software. It helps streamline labeling processes, ensures accuracy, and maintains compliance with industry standards.

10.3 What are the key features to look for in care label printing software?

Key features include a user-friendly interface, customizable templates, barcode and QR code generation, database integration, compliance features, flexible printing options, and integration with other systems.

10.4 How does care label printing software help with compliance?

Care label printing software helps ensure that labels contain all the necessary information required by compliance standards, meet formatting requirements, automate compliance checks, reduce the risk of errors, and maintain an audit trail.

10.5 What are the latest trends in care label printing software?

Latest trends include cloud-based solutions, mobile printing, integration with IoT devices, enhanced data management, artificial intelligence (AI), and sustainability.

10.6 How do I choose the right care label printing software for my needs?

Assess your specific needs, evaluate software features, consider ease of use, check compatibility, read reviews and testimonials, request a demo or trial, consider scalability, evaluate customer support, consider cloud-based vs. on-premise solutions, and review pricing and licensing options.

10.7 What are some common mistakes to avoid when using care label printing software?

Common mistakes include neglecting software training, ignoring compliance standards, overlooking label design best practices, failing to calibrate printers, using the wrong label stock, neglecting data validation, and ignoring software updates.

10.8 Can care label printing software integrate with my existing systems?

Yes, many care label printing software solutions offer integration with other systems, such as ERP, WMS, and CRM. This can streamline your workflow and improve efficiency.

10.9 How much does care label printing software cost?

The cost of care label printing software varies depending on the features, functionality, and licensing options. Some software is sold as a one-time purchase, while others are subscription-based.

10.10 Where can I find more information about care label printing software?

You can find more information about care label printing software by researching online, reading reviews, contacting software vendors, and attending industry events.

Ready to enhance your automotive repair skills with care label printing software? Visit CAR-REMOTE-REPAIR.EDU.VN today to explore our comprehensive training programs and unlock your potential! Call us at +1 (641) 206-8880, or visit us at 1700 W Irving Park Rd, Chicago, IL 60613, United States.

Technician using care label printing software

Technician using care label printing software

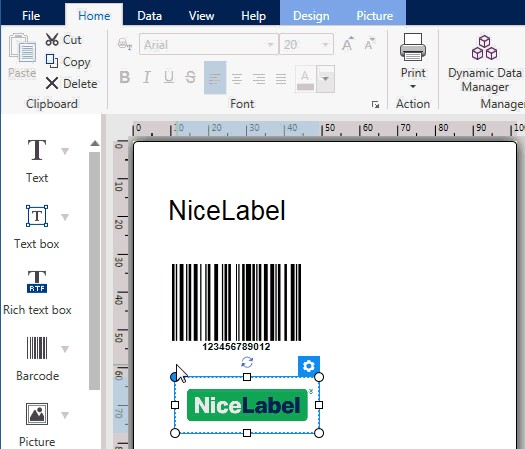

Automotive technician using NiceLabel Designer 2017 software to create a customized care label with part details.

Carefree Logo

Carefree Logo

Carefree logo for apparel cloth labels, emphasizing user-friendly features and flexible label sizing.

By mastering care label printing software, you can enhance your diagnostic skills, improve communication with customers, and ensure that you are always in compliance with industry standards.