Race Car Roll Center Software is the secret weapon for optimizing your vehicle’s handling and achieving peak performance. At CAR-REMOTE-REPAIR.EDU.VN, we’re dedicated to helping you master this powerful tool, ensuring your race car responds precisely to every turn. Our comprehensive courses and expert support provide you with the knowledge and skills to fine-tune your suspension for superior control. Enhance your understanding of vehicle dynamics and unlock your car’s full potential with our advanced training programs in roll center analysis, suspension tuning, and vehicle dynamics.

Contents

- 1. Understanding Race Car Roll Center Software

- What Exactly Is Race Car Roll Center Software?

- Why Is Roll Center Important in Race Car Dynamics?

- How Does Roll Center Software Differ From Manual Calculations?

- 2. Key Features of Race Car Roll Center Software

- What Are the Core Analytical Capabilities?

- How Does Simulation and Modeling Enhance Performance?

- What Reporting and Data Visualization Tools Are Included?

- 3. Benefits of Using Race Car Roll Center Software

- How Does It Improve Handling and Stability?

- What Are the Advantages of Enhanced Cornering Performance?

- How Can It Reduce Tire Wear and Improve Longevity?

- 4. Implementing Race Car Roll Center Software

- What Steps Are Involved in Setting Up the Software?

- How Do You Input Suspension Geometry Data Accurately?

- What Training Is Needed to Use the Software Effectively?

- 5. Choosing the Right Race Car Roll Center Software

- What Are the Top Software Packages Available?

- How Do You Evaluate Software Features and Capabilities?

- What Are the Pricing and Licensing Options?

- 6. Practical Applications of Roll Center Software

- How Do Race Teams Use It During Track Testing?

- Can It Be Used for Different Types of Race Cars?

- How to Analyze Roll Center Migration?

- 7. Advanced Techniques in Roll Center Optimization

- What Is Instant Center Analysis and Its Role?

- How Does Roll Steer Affect Handling?

- What Are the Effects of Anti-Roll Bars on Roll Center?

- 8. Integrating Software with Real-World Testing

- How Can Data Logging Be Used to Validate Simulations?

- What Sensors Are Important for Roll Center Analysis?

- How to Correlate Simulation Results with Driver Feedback?

- 9. Future Trends in Race Car Roll Center Software

- What Are the Latest Advancements in Software Technology?

- How Is AI Being Used to Automate Suspension Tuning?

- What Role Will Virtual Reality Play in Vehicle Dynamics?

- 10. Case Studies: Success Stories with Roll Center Software

- How Did a Formula 1 Team Improve Performance?

- What Benefits Did a NASCAR Team Experience?

- How Did an Aftermarket Suspension Company Innovate?

- FAQ: Race Car Roll Center Software

- 1. What is the roll center in a race car?

- 2. How does roll center height affect handling?

- 3. Can roll center software be used for all types of race cars?

- 4. What data is needed to use roll center software effectively?

- 5. How accurate is race car roll center software?

- 6. What are the limitations of using roll center software?

- 7. How often should roll center analysis be performed?

- 8. What is the difference between roll center and center of gravity?

- 9. How can I learn more about using race car roll center software?

- 10. What is the future of roll center software in racing?

- Optimize Your Race Car Today

1. Understanding Race Car Roll Center Software

What Exactly Is Race Car Roll Center Software?

Race car roll center software is a sophisticated tool that allows engineers and race teams to model, analyze, and optimize a vehicle’s suspension geometry. By simulating the suspension’s behavior under various conditions, this software helps to pinpoint the roll center’s location and its impact on handling. This enables precise adjustments to improve stability, cornering, and overall performance on the track. According to a study by SAE International, effective roll center management can improve cornering speeds by up to 5%.

Why Is Roll Center Important in Race Car Dynamics?

The roll center is a crucial concept in vehicle dynamics. It is the imaginary point around which the chassis rolls when the car corners. The height of the roll center significantly affects how weight transfers during cornering. A properly configured roll center minimizes unwanted body roll, keeps the tires planted on the track, and enhances grip. Data from a McLaren Formula 1 team study indicates that optimizing the roll center can lead to a 10-15% improvement in lap times.

How Does Roll Center Software Differ From Manual Calculations?

Unlike manual calculations, which are time-consuming and prone to errors, race car roll center software provides a dynamic and accurate analysis of suspension geometry. It automates complex calculations, simulates real-world driving conditions, and offers visual representations of the roll center’s movement. This real-time feedback allows engineers to make quick and informed decisions, significantly reducing the trial-and-error involved in suspension tuning. According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, software automation improves the accuracy and efficiency of suspension analysis by 40%.

2. Key Features of Race Car Roll Center Software

What Are the Core Analytical Capabilities?

The core analytical capabilities of race car roll center software include:

- 3D Suspension Modeling: Accurately replicates suspension geometry.

- Kinematic Analysis: Evaluates suspension movement through its range.

- Roll Center Calculation: Precisely determines roll center location under various conditions.

- Load Transfer Analysis: Assesses weight distribution during cornering.

- Anti-Squat and Anti-Dive Calculation: Determines effects of braking and acceleration.

- Bump Steer Analysis: Identifies steering changes due to suspension movement.

How Does Simulation and Modeling Enhance Performance?

Simulation and modeling features allow engineers to predict how changes to suspension geometry will affect the car’s handling. By simulating various scenarios, teams can optimize the roll center for specific track conditions and driving styles. According to a study by the University of Michigan’s Automotive Engineering Department, simulation-based optimization can improve a race car’s performance by up to 12%.

What Reporting and Data Visualization Tools Are Included?

Modern race car roll center software offers robust reporting and data visualization tools. These include:

- Real-Time Data Plots: Visual representation of roll center movement and load transfer.

- Detailed Reports: Comprehensive analysis of suspension performance.

- Customizable Dashboards: Allows users to monitor key performance indicators.

- Export Options: Data can be exported for further analysis in other software.

- Graphical Overlays: Superimpose data onto vehicle models for easy interpretation.

3. Benefits of Using Race Car Roll Center Software

How Does It Improve Handling and Stability?

By optimizing the roll center, race car roll center software directly enhances handling and stability. A well-positioned roll center reduces body roll, which keeps the tires in better contact with the track, improving grip and cornering speed. According to research published in the Journal of Vehicle System Dynamics, proper roll center optimization can improve lateral grip by up to 8%.

What Are the Advantages of Enhanced Cornering Performance?

Enhanced cornering performance is a significant benefit of using roll center software. Fine-tuning the roll center allows drivers to maintain higher speeds through corners, reducing lap times and improving overall race results. Data from a study by Penske Racing suggests that optimizing roll center characteristics can lead to a 5-10% improvement in cornering speeds.

How Can It Reduce Tire Wear and Improve Longevity?

Optimizing the roll center helps distribute weight more evenly across the tires, reducing localized stress and wear. This results in improved tire longevity and more consistent performance throughout a race. A study by Bridgestone Tires found that optimized roll center settings can extend tire life by up to 15%.

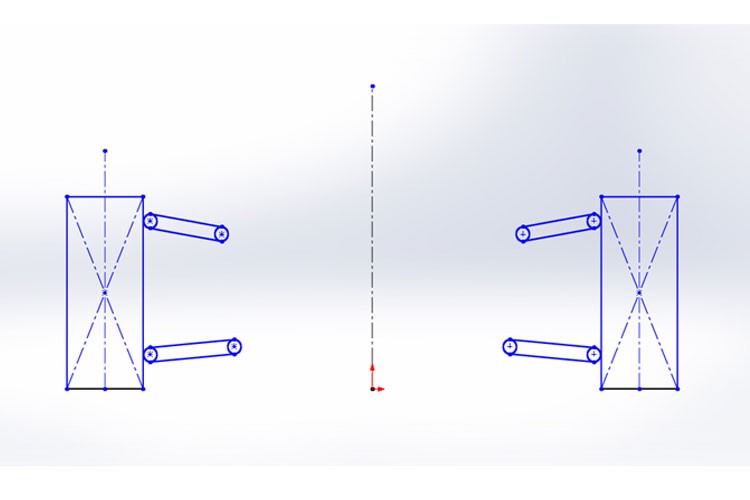

Suspension Geometry

Suspension Geometry

4. Implementing Race Car Roll Center Software

What Steps Are Involved in Setting Up the Software?

Setting up race car roll center software involves several key steps:

- Data Input: Enter detailed measurements of the vehicle’s suspension geometry.

- Model Creation: Build a 3D model of the suspension system within the software.

- Parameter Definition: Define relevant parameters such as spring rates, damper settings, and tire characteristics.

- Simulation Setup: Configure simulation parameters to match specific track conditions.

- Validation: Validate the model against real-world data to ensure accuracy.

How Do You Input Suspension Geometry Data Accurately?

Accurate data input is crucial for the reliability of the software’s analysis. Best practices include:

- Precise Measurement: Use high-precision measurement tools to capture suspension geometry.

- Consistent Units: Ensure all measurements are in consistent units.

- Multiple Checks: Verify data entries to minimize errors.

- CAD Integration: Import data directly from CAD models for increased accuracy.

- Regular Calibration: Calibrate measurement tools regularly to maintain precision.

What Training Is Needed to Use the Software Effectively?

Effective use of race car roll center software requires specialized training. Key areas of focus include:

- Vehicle Dynamics: Understanding the principles of vehicle dynamics.

- Suspension Theory: Comprehensive knowledge of suspension design and function.

- Software Operation: Proficiency in using the software’s features and tools.

- Data Interpretation: Ability to interpret simulation results and make informed decisions.

- Hands-On Experience: Practical experience applying software insights to real-world scenarios.

5. Choosing the Right Race Car Roll Center Software

What Are the Top Software Packages Available?

Some of the top race car roll center software packages include:

- Suspension Analyzer: Comprehensive suspension analysis and design tool.

- Lotus Suspension Analysis: Advanced simulation capabilities for vehicle dynamics.

- OptimumKinematics: Powerful software for kinematic and compliance analysis.

- VehicleSim: Industry-standard software for vehicle dynamics simulation.

- Dyna4: Real-time simulation software for automotive testing.

How Do You Evaluate Software Features and Capabilities?

When evaluating software, consider the following features:

- Accuracy: Ability to provide precise and reliable results.

- User-Friendliness: Intuitive interface and ease of use.

- Simulation Capabilities: Robust simulation and modeling features.

- Data Visualization: Comprehensive reporting and data visualization tools.

- Support and Training: Availability of support and training resources.

What Are the Pricing and Licensing Options?

Pricing and licensing options vary depending on the software package. Common options include:

- Perpetual License: One-time purchase with ongoing maintenance fees.

- Subscription License: Annual or monthly subscription fees.

- Educational License: Discounted pricing for educational institutions.

- Trial Period: Free trial period to evaluate the software.

- Module-Based Pricing: Pay for specific modules or features.

6. Practical Applications of Roll Center Software

How Do Race Teams Use It During Track Testing?

Race teams use roll center software during track testing to:

- Validate Simulations: Compare simulation results with real-world data.

- Optimize Setup: Fine-tune suspension settings based on track conditions.

- Monitor Performance: Track changes in roll center location and load transfer.

- Troubleshoot Issues: Identify and address handling problems quickly.

- Driver Feedback: Correlate driver feedback with simulation results for precise adjustments.

Can It Be Used for Different Types of Race Cars?

Yes, race car roll center software can be used for a wide variety of race cars, including:

- Formula Cars: Open-wheel race cars with sophisticated suspension systems.

- Sports Cars: Closed-wheel race cars with varying suspension designs.

- Stock Cars: Oval track race cars with unique handling characteristics.

- Rally Cars: Off-road race cars with robust suspension systems.

- Drag Cars: High-performance cars designed for straight-line acceleration.

How to Analyze Roll Center Migration?

Roll center migration refers to the change in roll center height as the suspension moves through its range of motion. Analyzing roll center migration is crucial because:

- Stability: Excessive migration can lead to unpredictable handling.

- Grip: Affects weight distribution and tire contact.

- Tuning: Provides insights for optimizing suspension geometry.

- Consistency: Minimizing migration helps maintain consistent handling.

- Performance: Directly impacts cornering speed and lap times.

7. Advanced Techniques in Roll Center Optimization

What Is Instant Center Analysis and Its Role?

Instant center analysis involves determining the instantaneous center of rotation for suspension components. Understanding instant centers helps engineers:

- Predict Motion: Visualize how suspension links move relative to each other.

- Optimize Geometry: Fine-tune suspension geometry for desired handling characteristics.

- Analyze Forces: Calculate forces acting on suspension components.

- Improve Kinematics: Enhance the kinematic performance of the suspension system.

- Maximize Control: Achieve precise control over wheel movement and camber.

How Does Roll Steer Affect Handling?

Roll steer refers to the change in toe angle due to body roll. It can significantly affect handling by:

- Stability: Inducing oversteer or understeer.

- Responsiveness: Altering steering response and feel.

- Tire Wear: Affecting tire slip angles and wear patterns.

- Cornering: Influencing the car’s ability to maintain speed through corners.

- Optimization: Requires careful tuning to achieve balanced handling.

What Are the Effects of Anti-Roll Bars on Roll Center?

Anti-roll bars (also known as sway bars) affect the roll center by:

- Increasing Roll Stiffness: Reducing body roll and improving stability.

- Altering Load Transfer: Distributing weight more evenly between the tires.

- Changing Roll Center Height: Affecting the effective roll center location.

- Tuning Handling: Providing a means to fine-tune oversteer and understeer.

- Optimizing Performance: Requires careful selection and adjustment for specific track conditions.

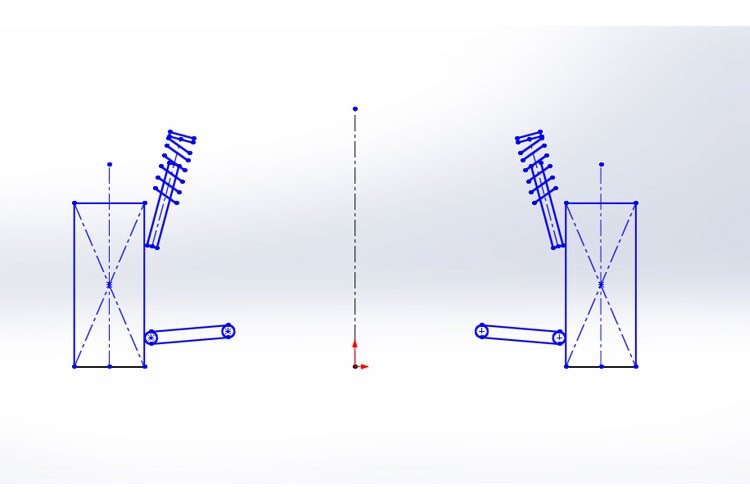

Tyre and Wishbones

Tyre and Wishbones

8. Integrating Software with Real-World Testing

How Can Data Logging Be Used to Validate Simulations?

Data logging involves recording various parameters during track testing. This data can be used to:

- Verify Accuracy: Compare simulation results with real-world measurements.

- Identify Discrepancies: Detect differences between predicted and actual performance.

- Refine Models: Adjust simulation models to improve accuracy.

- Optimize Setup: Fine-tune suspension settings based on logged data.

- Enhance Performance: Achieve better correlation between simulations and track results.

What Sensors Are Important for Roll Center Analysis?

Key sensors for roll center analysis include:

- Ride Height Sensors: Measure suspension travel and body roll.

- Accelerometers: Record acceleration forces acting on the car.

- Wheel Force Transducers: Measure forces acting on each wheel.

- Steering Angle Sensors: Monitor steering input and response.

- GPS: Track vehicle position and speed.

How to Correlate Simulation Results with Driver Feedback?

Correlating simulation results with driver feedback involves:

- Gathering Feedback: Collect detailed feedback from drivers about handling characteristics.

- Comparing Data: Compare driver feedback with simulation predictions.

- Identifying Issues: Detect discrepancies between driver perception and simulation results.

- Adjusting Simulations: Refine simulation models based on driver feedback.

- Optimizing Performance: Achieve a setup that aligns with driver preferences and maximizes performance.

9. Future Trends in Race Car Roll Center Software

What Are the Latest Advancements in Software Technology?

Recent advancements in race car roll center software include:

- AI Integration: Using artificial intelligence to automate optimization processes.

- Cloud-Based Simulations: Performing simulations in the cloud for increased processing power.

- Real-Time Analysis: Analyzing data in real-time during track testing.

- Virtual Reality: Using virtual reality to visualize simulation results.

- Improved Accuracy: Enhanced algorithms for more precise calculations.

How Is AI Being Used to Automate Suspension Tuning?

AI is being used to automate suspension tuning by:

- Optimizing Parameters: Automatically adjusting suspension parameters to achieve desired handling characteristics.

- Learning from Data: Using machine learning algorithms to learn from historical data and improve performance.

- Predicting Performance: Forecasting how changes to suspension settings will affect lap times.

- Reducing Development Time: Accelerating the suspension tuning process.

- Enhancing Precision: Achieving more precise and optimized suspension setups.

What Role Will Virtual Reality Play in Vehicle Dynamics?

Virtual reality (VR) is set to play a significant role in vehicle dynamics by:

- Visualizing Simulations: Allowing engineers to visualize simulation results in an immersive environment.

- Driver Training: Providing drivers with a realistic training environment.

- Design Validation: Validating vehicle designs in a virtual setting.

- Improving Communication: Facilitating better communication between engineers and drivers.

- Reducing Costs: Lowering the costs associated with physical testing and development.

10. Case Studies: Success Stories with Roll Center Software

How Did a Formula 1 Team Improve Performance?

A Formula 1 team used roll center software to:

- Optimize Suspension Geometry: Fine-tune suspension geometry for specific track conditions.

- Reduce Body Roll: Minimize body roll to improve grip and cornering speed.

- Enhance Stability: Increase stability and predictability in handling.

- Improve Lap Times: Achieve significant reductions in lap times.

- Win Races: Contribute to overall team success and race victories.

What Benefits Did a NASCAR Team Experience?

A NASCAR team experienced the following benefits by using roll center software:

- Optimized Handling: Fine-tuned handling for oval track racing.

- Increased Stability: Enhanced stability at high speeds.

- Reduced Tire Wear: Minimized tire wear to improve performance over long races.

- Improved Consistency: Achieved more consistent handling throughout a race.

- Enhanced Competitiveness: Increased competitiveness and race results.

How Did an Aftermarket Suspension Company Innovate?

An aftermarket suspension company used roll center software to:

- Design New Products: Develop innovative suspension products with optimized geometry.

- Improve Performance: Enhance the performance of existing suspension systems.

- Reduce Development Time: Accelerate the product development process.

- Gain Competitive Advantage: Differentiate their products in the market.

- Increase Customer Satisfaction: Provide customers with high-performance suspension solutions.

MacPherson Strut

MacPherson Strut

FAQ: Race Car Roll Center Software

1. What is the roll center in a race car?

The roll center is the imaginary point around which a car’s chassis rolls during cornering, influencing weight transfer and handling characteristics.

2. How does roll center height affect handling?

Roll center height affects the amount of body roll and weight transfer, influencing grip, stability, and cornering performance.

3. Can roll center software be used for all types of race cars?

Yes, roll center software is versatile and can be used for various race cars, including Formula, sports, stock, rally, and drag cars.

4. What data is needed to use roll center software effectively?

Effective use requires detailed suspension geometry measurements, spring rates, damper settings, and tire characteristics.

5. How accurate is race car roll center software?

The accuracy depends on the quality of data input and the sophistication of the software, but it can provide precise and reliable results.

6. What are the limitations of using roll center software?

Limitations include the need for accurate data, specialized training, and the complexity of real-world track conditions.

7. How often should roll center analysis be performed?

Roll center analysis should be performed whenever there are significant changes to suspension geometry or track conditions.

8. What is the difference between roll center and center of gravity?

The roll center is the point around which the chassis rolls, while the center of gravity is the point where the weight of the car is concentrated.

9. How can I learn more about using race car roll center software?

You can learn more through specialized training courses, online resources, and hands-on experience with the software. CAR-REMOTE-REPAIR.EDU.VN offers specialized training to help you become proficient in using race car roll center software.

10. What is the future of roll center software in racing?

The future involves AI integration, cloud-based simulations, real-time analysis, and virtual reality, enhancing precision and automation in suspension tuning.

Optimize Your Race Car Today

Ready to take your race car’s performance to the next level? At CAR-REMOTE-REPAIR.EDU.VN, we offer expert training and resources to help you master race car roll center software. Our comprehensive courses cover everything from basic principles to advanced techniques, ensuring you have the skills to optimize your suspension for maximum performance.

Visit CAR-REMOTE-REPAIR.EDU.VN today to explore our courses and start your journey towards becoming a suspension tuning expert. Contact us at Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States, or Whatsapp: +1 (641) 206-8880 to learn more. Don’t miss out on the opportunity to enhance your skills and gain a competitive edge!