The Best 3d Car Design Software helps automotive professionals create innovative and efficient vehicle designs. At CAR-REMOTE-REPAIR.EDU.VN, we understand the importance of having the right tools to excel in this field. Explore top options that can transform your design process, offering features for sketching, modeling, and visualization, and stay ahead in the competitive automotive industry by mastering cutting-edge design techniques, automotive CAD software, and digital prototyping.

Contents

- 1. What is 3D Car Design Software?

- 1.1 Key Features of 3D Car Design Software

- 1.2 Applications in Automotive Design

- 1.3 Benefits of Using 3D Car Design Software

- 2. What Are The Essential Features To Look For in 3D Car Design Software?

- 2.1 Surface Modeling Capabilities

- 2.2 Parametric Design

- 2.3 Real-Time Rendering

- 2.4 Simulation Tools

- 2.5 Compatibility with Industry-Standard File Formats

- 3. What are The Best 3D Car Design Software Options Available?

- 3.1 CATIA

- 3.1.1 Key Features of CATIA

- 3.1.2 Pros and Cons of CATIA

- 3.1.3 Who Should Use CATIA?

- 3.2 Autodesk Alias

- 3.2.1 Key Features of Autodesk Alias

- 3.2.2 Pros and Cons of Autodesk Alias

- 3.2.3 Who Should Use Autodesk Alias?

- 3.3 SolidWorks

- 3.3.1 Key Features of SolidWorks

- 3.3.2 Pros and Cons of SolidWorks

- 3.3.3 Who Should Use SolidWorks?

- 3.4 Blender

- 3.4.1 Key Features of Blender

- 3.4.2 Pros and Cons of Blender

- 3.4.3 Who Should Use Blender?

- 4. How Do You Choose The Right 3D Car Design Software?

- 4.1 Assess Your Design Needs

- 4.2 Consider Your Budget

- 4.3 Evaluate Your Level of Expertise

- 4.4 Identify Desired Features

- 4.5 Take Advantage of Free Trials

- 5. How Can 3D Car Design Software Improve Automotive Design Efficiency?

- 5.1 Streamlined Workflows

- 5.2 Virtual Prototyping

- 5.3 Enhanced Collaboration

- 5.4 Automated Design Tasks

- 5.5 Real-Time Feedback and Iteration

- 6. What Role Does 3D Car Design Software Play in Electric Vehicle (EV) Development?

- 6.1 Design and Optimization of EV-Specific Components

- 6.2 Enhanced Aerodynamic Efficiency

- 6.3 Integration of New Technologies

- 6.4 Lightweighting

- 6.5 Thermal Management

- 7. How Does 3D Car Design Software Help in Prototyping and Testing?

- 7.1 Virtual Simulations

- 7.2 Early Flaw Detection

- 7.3 Reduced Need for Physical Prototypes

- 7.4 Cost-Effective Development

- 7.5 Faster Development Cycles

- 8. What Are The Latest Trends In 3D Car Design Software?

- 8.1 Artificial Intelligence (AI) Integration

- 8.2 Cloud-Based Collaboration

- 8.3 VR/AR Visualization

- 8.4 Generative Design

- 8.5 Advanced Simulation Tools

- 9. How Can Automotive Professionals Stay Updated on the Latest 3D Car Design Software?

- 9.1 Attend Industry Conferences

- 9.2 Participate in Online Forums

- 9.3 Take Online Courses

- 9.4 Read Industry Publications

- 9.5 Join Professional Organizations

- 10. What Are Some Common Challenges Faced When Using 3D Car Design Software and How to Overcome Them?

- 10.1 Steep Learning Curve

- 10.2 High Software Costs

- 10.3 Compatibility Issues

- 10.4 Need for Continuous Training

- 10.5 Hardware Requirements

- FAQ Section

- Q1: What is the best 3D car design software for beginners?

- Q2: How much does 3D car design software cost?

- Q3: Can I use 3D car design software on a Mac?

- Q4: What file formats are compatible with 3D car design software?

- Q5: Do I need a powerful computer to run 3D car design software?

- Q6: Is it possible to collaborate with others using 3D car design software?

- Q7: How long does it take to learn 3D car design software?

- Q8: What are the career opportunities for professionals skilled in 3D car design software?

- Q9: How does 3D car design software help in reducing manufacturing costs?

- Q10: Can I use 3D car design software for personal car customization projects?

1. What is 3D Car Design Software?

3D car design software is a specialized set of computer-aided design (CAD) tools used by automotive designers and engineers to create, modify, and visualize vehicle designs in three dimensions. It’s essential for modern automotive development, enabling detailed modeling, simulation, and analysis of vehicle components and systems.

1.1 Key Features of 3D Car Design Software

3D car design software typically includes features such as parametric modeling, surface modeling, assembly design, rendering, and simulation capabilities. Parametric modeling allows designers to easily modify designs by changing parameters, while surface modeling is crucial for creating complex and aesthetically pleasing vehicle surfaces. Assembly design enables the integration of various components into a complete vehicle model, and rendering tools provide realistic visualizations for presentations and marketing. Simulation capabilities allow engineers to analyze the performance of designs under different conditions.

1.2 Applications in Automotive Design

The applications of 3D car design software span the entire automotive development process, from initial concept design to manufacturing. Designers use the software to create concept models, refine designs based on feedback, and generate detailed engineering drawings for production. It also facilitates collaboration among different teams, such as design, engineering, and manufacturing, by providing a common platform for sharing and reviewing designs.

1.3 Benefits of Using 3D Car Design Software

The benefits of using 3D car design software are numerous. It enhances design accuracy, reduces development time, and lowers costs by enabling virtual prototyping and simulation. Designers can identify and resolve potential issues early in the design process, minimizing the need for physical prototypes. Moreover, it fosters innovation by allowing designers to explore various design options and push the boundaries of automotive aesthetics and functionality. According to a study by the National Institute of Standards and Technology (NIST), the implementation of CAD software can reduce design errors by up to 40%.

2. What Are The Essential Features To Look For in 3D Car Design Software?

Essential features to look for in 3D car design software include robust surface modeling capabilities, parametric design, real-time rendering, simulation tools, and compatibility with industry-standard file formats. These features ensure designers can create visually appealing and functional designs efficiently.

2.1 Surface Modeling Capabilities

Surface modeling is essential for creating the complex and aerodynamic shapes of modern vehicles. The software should offer tools for creating and manipulating NURBS (Non-Uniform Rational B-Splines) surfaces, which provide a smooth and accurate representation of vehicle exteriors.

2.2 Parametric Design

Parametric design allows designers to create models where changes to one parameter automatically update related features. This is crucial for making quick design iterations and ensuring consistency across the entire vehicle model. According to research from the University of Michigan’s Transportation Research Institute (UMTRI), parametric design can reduce design iteration time by up to 30%.

2.3 Real-Time Rendering

Real-time rendering provides immediate visual feedback on design changes, allowing designers to evaluate aesthetics and lighting effects without waiting for lengthy rendering processes. This feature enhances the design workflow and enables better communication of design ideas.

2.4 Simulation Tools

Simulation tools enable engineers to analyze the performance of vehicle designs under various conditions, such as aerodynamic drag, structural stress, and thermal behavior. These tools help identify potential issues early in the design process and optimize designs for performance and safety.

2.5 Compatibility with Industry-Standard File Formats

Compatibility with industry-standard file formats, such as STEP, IGES, and STL, is essential for seamless collaboration with other design and engineering teams. This ensures that designs can be easily shared and integrated into different software environments.

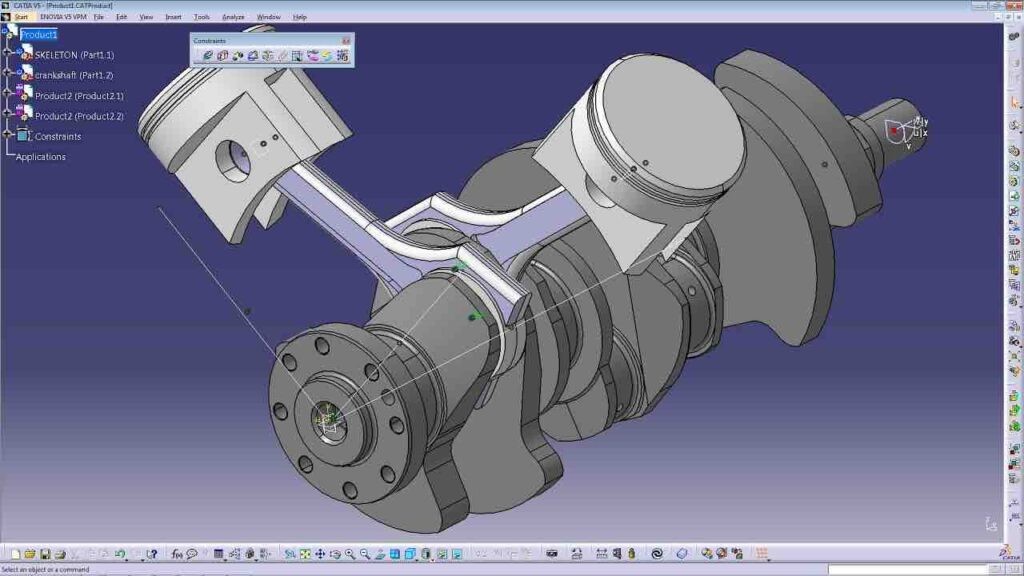

CAD Modelling Software for Automotive Applications

CAD Modelling Software for Automotive Applications

3. What are The Best 3D Car Design Software Options Available?

The best 3D car design software options include CATIA, Autodesk Alias, SolidWorks, and Blender, each offering unique features and capabilities tailored to different aspects of automotive design. These tools provide a range of functionalities, from surface modeling to rendering, ensuring designers can create visually stunning and highly functional vehicle designs.

3.1 CATIA

CATIA (Computer-Aided Three Dimensional Interactive Application) is a multi-platform software suite developed by Dassault Systèmes. It stands out as a top-tier solution for surface modeling and is extensively used for 3D design, CAE (Computer-Aided Engineering), and PLM (Product Lifecycle Management). CATIA is used for designing everything from fluid and electronic systems to mechanical engineering and structural components, offering a comprehensive toolset for automotive product development.

3.1.1 Key Features of CATIA

CATIA excels in surface and solid modeling, electronic systems design, and product lifecycle management. Its advanced tools are suitable for designing chassis, powertrains, and Class A surfaces, making it a staple in the automotive industry. The software integrates seamlessly with other tools in the Dassault Systèmes suite, enhancing collaborative design and engineering processes.

3.1.2 Pros and Cons of CATIA

Pros:

- Advanced Surface Modeling: CATIA’s superior surface modeling tools are unparalleled, allowing for precise and complex designs.

- Comprehensive Functionality: It offers a wide array of tools for design, engineering, and product lifecycle management.

- Industry Standard: Widely adopted by major automotive manufacturers.

Cons:

- High Cost: CATIA is one of the more expensive options, with perpetual licenses costing upwards of $11,000 plus annual maintenance fees.

- Steep Learning Curve: Its extensive functionality can be overwhelming for new users.

3.1.3 Who Should Use CATIA?

CATIA is best suited for large automotive companies and experienced designers who require advanced capabilities for complex projects. It is also a great tool to learn more about at CAR-REMOTE-REPAIR.EDU.VN to enhance your skillset in automotive design.

3.2 Autodesk Alias

Autodesk Alias is a specialized CAD software used primarily for automotive and industrial design. It is known for its ability to generate Class A surfaces using Bézier surface and NURBS modeling methods. Companies like Tesla, Aston Martin, and Lucid Motors rely on Alias for their automotive design needs.

3.2.1 Key Features of Autodesk Alias

Alias provides tools for sketching, modeling, surface design, and visualization. It supports industrial, automotive, and product design, making it ideal for creating high-quality, aesthetically pleasing vehicle exteriors.

3.2.2 Pros and Cons of Autodesk Alias

Pros:

- Class A Surface Design: Unmatched capabilities for designing Class A surfaces.

- Industry Adoption: Widely used by leading automotive companies.

- Comprehensive Toolset: Offers tools for sketching, modeling, and visualization.

Cons:

- Specialized Use: Primarily focused on surface modeling, which may not be suitable for all design tasks.

- Cost: Can be expensive, particularly for small businesses or individual designers.

3.2.3 Who Should Use Autodesk Alias?

Autodesk Alias is ideal for automotive designers who specialize in exterior design and require the highest quality surface modeling capabilities.

3.3 SolidWorks

SolidWorks, also developed by Dassault Systèmes, is a solid modeling software known for its user-friendly interface and versatile capabilities. It is widely used in the automotive and transportation industries for design and mechanical part creation.

3.3.1 Key Features of SolidWorks

SolidWorks includes solutions for visualizing, simulating, and developing electrical systems, as well as CAM and surfacing tools. It allows for quick virtual validation of designs, reducing manufacturing time and making it an excellent choice for complete 3D CAD modeling.

3.3.2 Pros and Cons of SolidWorks

Pros:

- User-Friendly Interface: Easier to use than CATIA, making it accessible to a wider range of users.

- Versatile Capabilities: Suitable for design and mechanical part creation.

- Virtual Validation: Allows for quick virtual validation of designs, reducing manufacturing time.

Cons:

- Limited Functionality Compared to CATIA: Not as comprehensive as CATIA in terms of CAE and PLM capabilities.

- Cost: Perpetual licenses can be expensive, although less so than CATIA.

3.3.3 Who Should Use SolidWorks?

SolidWorks is best for automotive designers and engineers who need a user-friendly and versatile tool for creating mechanical parts and validating designs.

3.4 Blender

Blender is a free and open-source 3D modeling application used for modeling, texturing, rigging, animation, and more. While it is commonly associated with character modeling, it is also a capable program for designing complex geometries like cars.

3.4.1 Key Features of Blender

Blender includes simulation tools and supports polygon meshes and NURBS. It facilitates the design of complex geometries and can reduce design time, allowing for faster design decisions. Tata Motors is known to use Blender for first-level car model design.

3.4.2 Pros and Cons of Blender

Pros:

- Free and Open-Source: No licensing fees, making it accessible to everyone.

- Versatile: Suitable for a wide range of design tasks, including modeling, texturing, and animation.

- Large Community: Extensive online resources and community support.

Cons:

- Steep Learning Curve: Can be challenging for beginners due to its complex interface.

- Limited Functionality Compared to Commercial Software: May not offer the same level of precision and advanced features as paid software.

3.4.3 Who Should Use Blender?

Blender is ideal for hobbyists, students, and small businesses looking for a free and versatile 3D modeling tool. It is also suitable for initial design exploration before moving to more specialized software.

Catia Automotive design and assembly

Catia Automotive design and assembly

4. How Do You Choose The Right 3D Car Design Software?

Choosing the right 3D car design software involves assessing your specific design needs, budget, level of expertise, and desired features. Understanding these factors will guide you to select the software that best fits your requirements.

4.1 Assess Your Design Needs

Start by evaluating the types of automotive designs you will be working on. If you need to create complex Class A surfaces for exterior design, Autodesk Alias might be the best choice. If you require a comprehensive tool for mechanical part design and simulation, SolidWorks or CATIA could be more suitable.

4.2 Consider Your Budget

3D car design software varies significantly in price. Open-source options like Blender are free, while commercial software like CATIA and Autodesk Alias can be quite expensive. Consider your budget and whether the software’s features justify the cost.

4.3 Evaluate Your Level of Expertise

Some software, like SolidWorks, is known for its user-friendly interface, making it easier for beginners to learn. Others, like CATIA and Blender, have a steeper learning curve and are better suited for experienced designers.

4.4 Identify Desired Features

Make a list of the features that are most important to you, such as surface modeling, parametric design, real-time rendering, and simulation tools. Compare the features offered by different software options to see which one best meets your needs.

4.5 Take Advantage of Free Trials

Many software companies offer free trials of their products. Take advantage of these trials to test out different software options and see which one works best for you.

5. How Can 3D Car Design Software Improve Automotive Design Efficiency?

3D car design software significantly improves automotive design efficiency by streamlining workflows, enabling virtual prototyping, and facilitating collaboration among design teams. These capabilities reduce design time and enhance overall productivity.

5.1 Streamlined Workflows

3D car design software streamlines the design process by providing a unified platform for all design tasks, from initial sketching to final engineering drawings. This eliminates the need to switch between different software applications, reducing the risk of errors and improving efficiency.

5.2 Virtual Prototyping

Virtual prototyping allows designers to create and test designs in a virtual environment, eliminating the need for physical prototypes. This saves time and money, as physical prototypes can be expensive and time-consuming to produce.

5.3 Enhanced Collaboration

3D car design software facilitates collaboration among design teams by providing a common platform for sharing and reviewing designs. This ensures that all team members are working from the same information, reducing the risk of misunderstandings and improving communication.

5.4 Automated Design Tasks

Many 3D car design software options include automation tools that can automate repetitive design tasks, such as generating engineering drawings and creating bills of materials. This frees up designers to focus on more creative and strategic tasks.

5.5 Real-Time Feedback and Iteration

Real-time rendering and simulation tools provide immediate feedback on design changes, allowing designers to quickly iterate and refine their designs. This accelerates the design process and ensures that designs are optimized for performance and aesthetics.

6. What Role Does 3D Car Design Software Play in Electric Vehicle (EV) Development?

3D car design software plays a crucial role in electric vehicle (EV) development by enabling the design and optimization of EV-specific components, enhancing aerodynamic efficiency, and facilitating the integration of new technologies.

6.1 Design and Optimization of EV-Specific Components

EVs require specialized components, such as battery packs, electric motors, and power electronics. 3D car design software enables designers to create and optimize these components for performance, weight, and thermal management.

6.2 Enhanced Aerodynamic Efficiency

Aerodynamic efficiency is particularly important for EVs, as it directly impacts their range and energy consumption. 3D car design software allows designers to optimize vehicle shapes for minimal drag, improving the overall efficiency of the EV.

6.3 Integration of New Technologies

EVs often incorporate new technologies, such as advanced driver-assistance systems (ADAS) and connected car features. 3D car design software facilitates the integration of these technologies into the vehicle design, ensuring they are seamlessly integrated and function effectively.

6.4 Lightweighting

Reducing the weight of EVs is crucial for improving their range and performance. 3D car design software enables designers to explore different materials and structural designs to minimize vehicle weight without compromising safety or performance. According to a report by the U.S. Department of Energy, lightweighting can improve EV range by up to 20%.

6.5 Thermal Management

Thermal management is critical for EVs, as the battery pack and electric motor generate significant heat. 3D car design software allows engineers to simulate and optimize the thermal performance of these components, ensuring they operate within safe temperature limits.

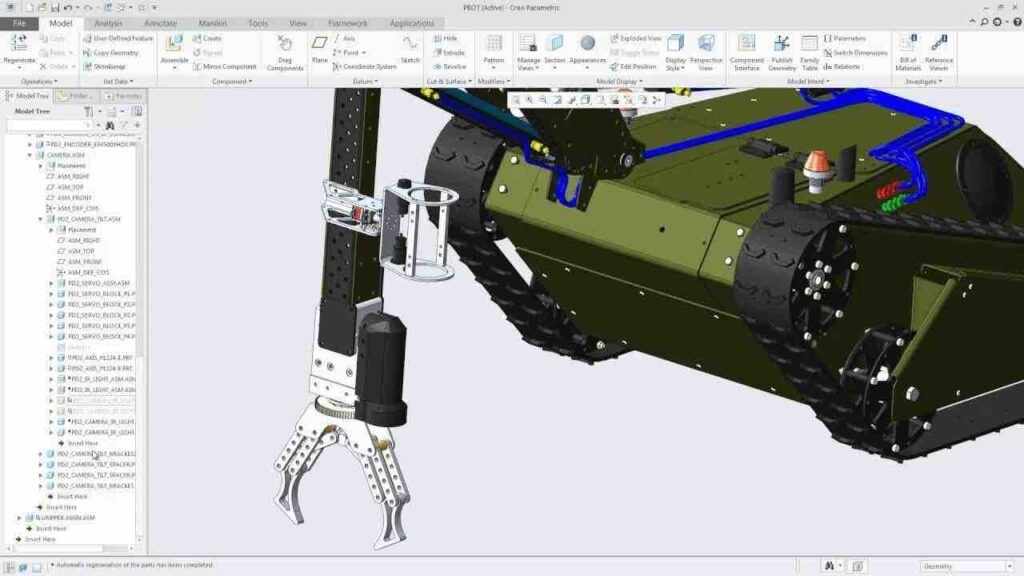

Creo Parametric for car engine design and simulation

Creo Parametric for car engine design and simulation

7. How Does 3D Car Design Software Help in Prototyping and Testing?

3D car design software is instrumental in prototyping and testing by enabling virtual simulations, identifying design flaws early, and reducing the need for physical prototypes, leading to faster and more cost-effective development cycles.

7.1 Virtual Simulations

3D car design software allows engineers to conduct virtual simulations to test vehicle performance under various conditions. These simulations can assess aerodynamic drag, structural integrity, and thermal behavior, providing valuable insights without the need for physical prototypes.

7.2 Early Flaw Detection

By using simulation tools, designers can identify potential design flaws early in the development process. This allows for quick corrections and improvements, minimizing the risk of costly errors later on.

7.3 Reduced Need for Physical Prototypes

The accuracy and reliability of virtual simulations reduce the reliance on physical prototypes. This not only saves time and money but also allows for more design iterations and experimentation.

7.4 Cost-Effective Development

Reducing the number of physical prototypes significantly lowers development costs. Virtual testing and simulation are far more cost-effective, allowing companies to allocate resources more efficiently.

7.5 Faster Development Cycles

The combination of virtual simulations, early flaw detection, and reduced reliance on physical prototypes leads to faster development cycles. Designers can quickly iterate and refine their designs, bringing new vehicles to market more rapidly.

8. What Are The Latest Trends In 3D Car Design Software?

The latest trends in 3D car design software include the integration of artificial intelligence (AI), cloud-based collaboration, virtual reality (VR) and augmented reality (AR) visualization, and generative design techniques.

8.1 Artificial Intelligence (AI) Integration

AI is being integrated into 3D car design software to automate tasks, optimize designs, and provide intelligent recommendations. AI algorithms can analyze design data, identify patterns, and suggest improvements to enhance performance and aesthetics.

8.2 Cloud-Based Collaboration

Cloud-based 3D car design software enables real-time collaboration among design teams, regardless of their location. This facilitates seamless communication, design reviews, and data sharing, improving overall efficiency and productivity.

8.3 VR/AR Visualization

Virtual reality (VR) and augmented reality (AR) technologies are being used to visualize 3D car designs in immersive environments. This allows designers and stakeholders to experience the vehicle design in a realistic setting, providing valuable insights and feedback.

8.4 Generative Design

Generative design uses AI algorithms to automatically generate multiple design options based on specified constraints and objectives. This allows designers to explore a wider range of possibilities and identify innovative solutions that might not have been considered otherwise. According to research from Autodesk, generative design can reduce design time by up to 50%.

8.5 Advanced Simulation Tools

Advanced simulation tools are being integrated into 3D car design software to provide more accurate and comprehensive analysis of vehicle performance. These tools can simulate complex phenomena, such as crash dynamics, thermal behavior, and electromagnetic interference.

9. How Can Automotive Professionals Stay Updated on the Latest 3D Car Design Software?

Automotive professionals can stay updated on the latest 3D car design software by attending industry conferences, participating in online forums, taking online courses, and reading industry publications.

9.1 Attend Industry Conferences

Industry conferences, such as the SAE International World Congress and the Automotive Engineering Exposition, offer opportunities to learn about the latest 3D car design software and network with industry experts.

9.2 Participate in Online Forums

Online forums, such as those on CAD forums, provide a platform for discussing 3D car design software, sharing tips and tricks, and asking questions.

9.3 Take Online Courses

Online courses, such as those offered by Coursera and Udemy, provide comprehensive training on 3D car design software. These courses can help automotive professionals develop their skills and stay up-to-date on the latest features and techniques. CAR-REMOTE-REPAIR.EDU.VN also offers specialized courses to enhance your expertise.

9.4 Read Industry Publications

Industry publications, such as Automotive Engineering International and Automotive Design & Production, provide valuable insights into the latest trends and technologies in 3D car design software.

9.5 Join Professional Organizations

Joining professional organizations, such as the Society of Automotive Engineers (SAE), provides access to resources, training, and networking opportunities related to 3D car design software.

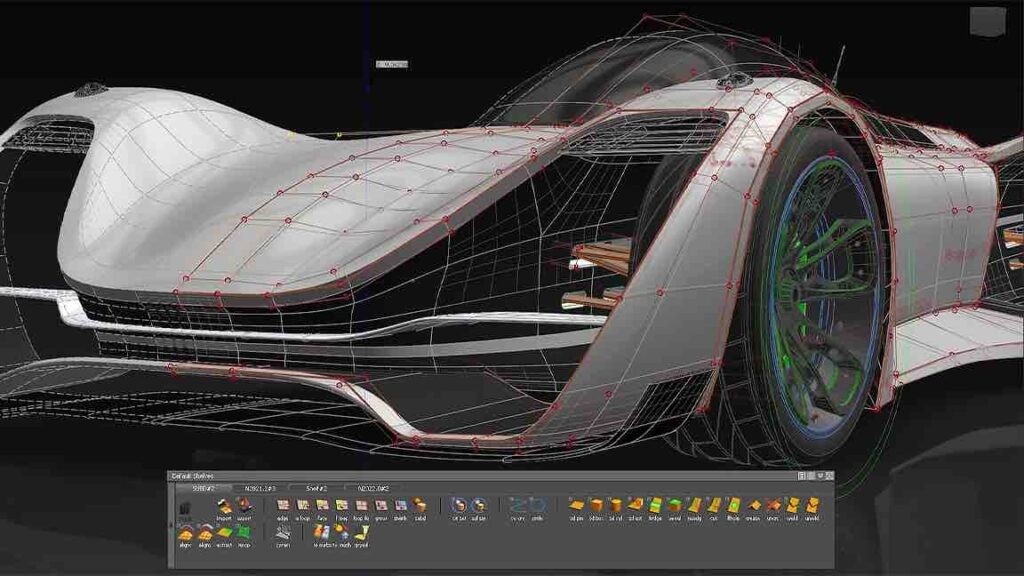

Autodesk Alias Software

Autodesk Alias Software

10. What Are Some Common Challenges Faced When Using 3D Car Design Software and How to Overcome Them?

Common challenges faced when using 3D car design software include a steep learning curve, high software costs, compatibility issues, and the need for continuous training. Overcoming these challenges involves investing in training, exploring open-source alternatives, and ensuring software compatibility.

10.1 Steep Learning Curve

Many 3D car design software options have a steep learning curve, particularly for beginners. This can be overcome by investing in training courses, tutorials, and hands-on practice. CAR-REMOTE-REPAIR.EDU.VN offers tailored courses to help professionals master these tools efficiently.

10.2 High Software Costs

Commercial 3D car design software can be expensive, particularly for small businesses and individual designers. This can be mitigated by exploring open-source alternatives, such as Blender, or considering subscription-based licensing models.

10.3 Compatibility Issues

Compatibility issues can arise when sharing designs between different software platforms or with external partners. This can be addressed by using industry-standard file formats, such as STEP and IGES, and ensuring that all team members are using compatible software versions.

10.4 Need for Continuous Training

3D car design software is constantly evolving, with new features and updates being released regularly. This requires continuous training to stay up-to-date on the latest techniques and best practices. CAR-REMOTE-REPAIR.EDU.VN provides ongoing training and support to help automotive professionals stay ahead of the curve.

10.5 Hardware Requirements

3D car design software can be resource-intensive, requiring powerful hardware to run smoothly. This can be addressed by investing in high-performance computers with fast processors, ample memory, and dedicated graphics cards.

By understanding and addressing these challenges, automotive professionals can maximize the benefits of 3D car design software and improve their design efficiency.

Ready to elevate your automotive design skills? Visit CAR-REMOTE-REPAIR.EDU.VN to explore our specialized training courses and discover how our remote support services can transform your design process. Contact us today at Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States, or via WhatsApp at +1 (641) 206-8880. Don’t miss the opportunity to become a leader in the future of automotive design.

FAQ Section

Q1: What is the best 3D car design software for beginners?

For beginners, SolidWorks and Blender are excellent choices due to their user-friendly interfaces and comprehensive toolsets. SolidWorks offers intuitive design tools, while Blender, being free and open-source, provides a cost-effective way to learn 3D modeling.

Q2: How much does 3D car design software cost?

The cost of 3D car design software varies widely. Open-source options like Blender are free, while commercial software such as SolidWorks can range from $4,000 for a perpetual license. More advanced software like CATIA can cost upwards of $11,000, plus annual maintenance fees.

Q3: Can I use 3D car design software on a Mac?

Yes, some 3D car design software options are compatible with macOS. However, compatibility can vary, so it’s essential to check the software requirements before purchasing. Software like Autodesk Alias and Blender work well on Mac.

Q4: What file formats are compatible with 3D car design software?

3D car design software typically supports industry-standard file formats such as STEP, IGES, STL, DWG, and DXF. These formats ensure seamless collaboration and data exchange between different software platforms.

Q5: Do I need a powerful computer to run 3D car design software?

Yes, 3D car design software can be resource-intensive, requiring a powerful computer with a fast processor, ample memory, and a dedicated graphics card. Check the software’s recommended hardware specifications to ensure optimal performance.

Q6: Is it possible to collaborate with others using 3D car design software?

Yes, many 3D car design software options offer collaboration features, such as cloud-based data sharing, real-time design reviews, and integrated communication tools. These features facilitate teamwork and improve design efficiency.

Q7: How long does it take to learn 3D car design software?

The time it takes to learn 3D car design software varies depending on the complexity of the software and the individual’s learning style. However, with dedicated training and practice, it is possible to become proficient in a few months.

Q8: What are the career opportunities for professionals skilled in 3D car design software?

Professionals skilled in 3D car design software can pursue various career opportunities in the automotive industry, including automotive designer, CAD designer, product engineer, and design engineer.

Q9: How does 3D car design software help in reducing manufacturing costs?

3D car design software helps reduce manufacturing costs by enabling virtual prototyping, identifying design flaws early, and optimizing designs for manufacturability. This reduces the need for physical prototypes and minimizes the risk of costly errors during production.

Q10: Can I use 3D car design software for personal car customization projects?

Yes, 3D car design software can be used for personal car customization projects. Whether you’re designing custom body kits, interior modifications, or performance enhancements, 3D car design software provides the tools and capabilities to bring your vision to life.