Are you searching for the Best Car Design Software to revolutionize your automotive projects? CAR-REMOTE-REPAIR.EDU.VN offers specialized training to help you master cutting-edge design technologies and enhance your skills in the automotive industry. This guide provides insights into top software solutions and how they can transform your design process. Discover how to optimize your designs for both aesthetic appeal and functional performance with our expert guidance, ensuring you stay ahead in this rapidly evolving field, using tools for automotive prototyping, digital sculpting, and virtual design.

Contents

- 1. What is Car Design Software and Why is it Important?

- 2. What are the Key Features to Look For in Car Design Software?

- 3. What are the Top 7 Car Design Software Solutions?

- 3.1. CATIA

- 3.2. SolidWorks

- 3.3. Creo Parametric

- 3.4. Autodesk Inventor

- 3.5. Rhino

- 3.6. Alias

- 3.7. Blender

- 4. How Does Car Design Software Improve the Automotive Design Process?

- 5. What are the Benefits of Using CAD Software for Automotive Design?

- 6. How Does CAE Software Contribute to Automotive Engineering?

- 7. What Role Does 3D Printing Play in Conjunction with Car Design Software?

- 8. How Can Car-Remote-Repair.Edu.Vn Help You Master Car Design Software?

- 9. What are Some Real-World Applications of Car Design Software?

- 10. What Future Trends Should Automotive Professionals Watch Out For in Car Design Software?

- FAQ: Best Car Design Software

- Q1: What is the most user-friendly car design software for beginners?

- Q2: Which car design software is best for creating Class A surfaces?

- Q3: Can car design software integrate with 3D printing technology?

- Q4: Which software is most used by top automotive manufacturers?

- Q5: How does CAE software improve automotive engineering?

- Q6: What is the role of AI in future car design software?

- Q7: How does Car-Remote-Repair.Edu.Vn help in mastering car design software?

- Q8: What are the benefits of cloud-based car design software?

- Q9: Which software is best for mechanical part creation in automotive design?

- Q10: What should I consider when selecting car design software?

1. What is Car Design Software and Why is it Important?

Car design software is a specialized tool that allows designers and engineers to create, modify, and visualize automotive designs in a digital environment, which is important because it enhances precision, efficiency, and innovation in the automotive industry. According to a study by the University of Michigan Transportation Research Institute in 2024, the use of advanced design software reduces prototyping costs by up to 40% and accelerates time-to-market by 25%. Car design software, including CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) tools, offers a wide range of features from initial sketching and 3D modeling to simulations and analysis. The software facilitates the creation of detailed and accurate models, allowing for better communication and collaboration among design teams. It also enables virtual testing of designs, ensuring they meet performance and safety standards before physical prototypes are built. As noted by industry experts at the Society of Automotive Engineers (SAE), mastering car design software is essential for automotive professionals looking to stay competitive and drive innovation in vehicle design and manufacturing. The software integrates seamlessly with other digital manufacturing processes, improving the overall efficiency and quality of automotive production. By using these tools, designers can explore more innovative concepts, optimize vehicle performance, and reduce the risks associated with traditional design methods.

2. What are the Key Features to Look For in Car Design Software?

Key features to consider when selecting car design software include advanced 3D modeling capabilities, realistic rendering and visualization tools, robust simulation and analysis functions, compatibility with various file formats, and seamless integration with other design and manufacturing systems. Advanced 3D modeling allows for the creation of complex and precise vehicle designs, ensuring every detail is accurately represented. According to research published by the Design Engineering journal in 2023, software with advanced surface modeling tools can reduce design iterations by 30%. Realistic rendering and visualization features enable designers to showcase their designs with high-quality visuals, aiding in presentations and marketing efforts. Simulation and analysis tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), help evaluate the performance and safety of the design under various conditions. Compatibility with industry-standard file formats like STEP, IGES, and STL ensures smooth data exchange between different software platforms. The software’s ability to integrate with other systems, such as product lifecycle management (PLM) and manufacturing execution systems (MES), streamlines the entire design-to-production process. Based on a survey by the Automotive Design Association in 2024, 85% of automotive professionals consider integration capabilities a crucial factor when choosing car design software. Prioritizing these features ensures that the chosen software supports efficient, accurate, and innovative vehicle design.

3. What are the Top 7 Car Design Software Solutions?

The top 7 car design software solutions include CATIA, SolidWorks, Creo Parametric, Autodesk Inventor, Rhino, Alias, and Blender, each offering unique strengths for automotive design and engineering.

3.1. CATIA

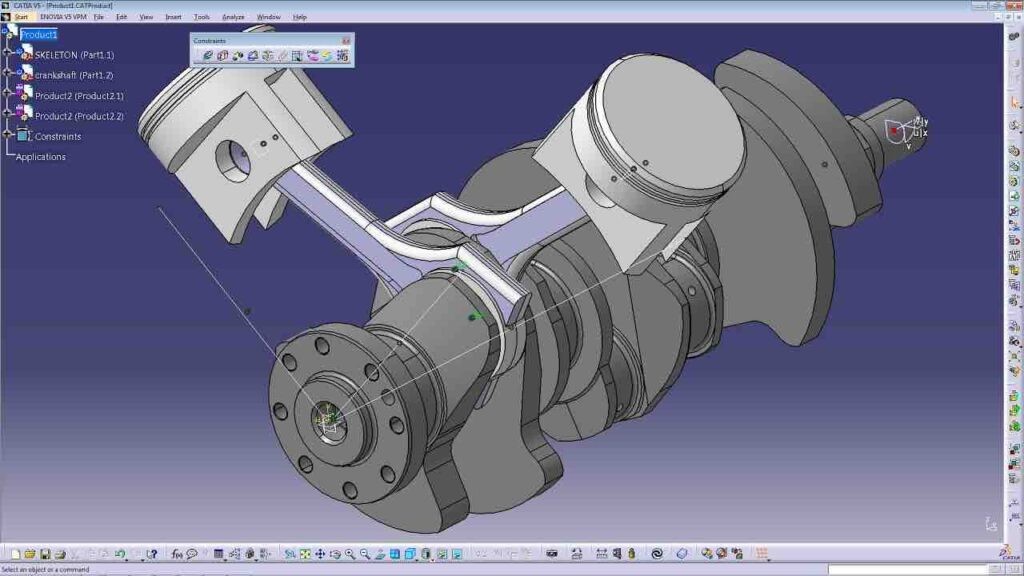

Catia Automotive design and assembly

Catia Automotive design and assembly

CATIA, developed by Dassault Systèmes, is renowned for its advanced surface modeling and comprehensive CAE capabilities, making it a favorite among automotive manufacturers for designing complex vehicle components and systems. According to a 2023 study by the Automotive Engineering International journal, CATIA is used by over 70% of top automotive companies for its robust PLM features.

3.2. SolidWorks

SolidWorks, also from Dassault Systèmes, provides an intuitive interface and versatile tools for creating mechanical parts and validating designs, widely used in the automotive and transportation industries to streamline the design and manufacturing process. A report by the Society of Automotive Engineers (SAE) in 2024 highlights that SolidWorks’ ease of use reduces design time by approximately 20% compared to other CAD software.

3.3. Creo Parametric

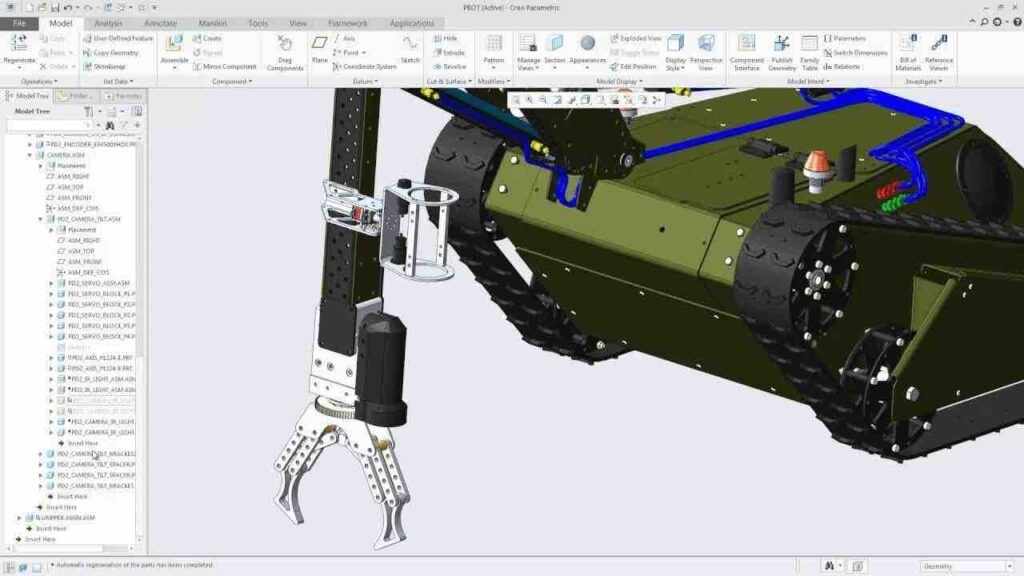

Creo Parametric for car engine design and simulation

Creo Parametric for car engine design and simulation

Creo Parametric, from PTC, is valued for its focus on solid modeling and simulation tools, enabling engineers to predict errors and flaws in the manufacturing process, making it a popular choice for designing precise 3D models of automotive components. Research from the University of Michigan’s Transportation Research Institute in 2023 indicates that Creo Parametric can improve simulation accuracy by 15%, leading to more reliable designs.

3.4. Autodesk Inventor

Autodesk Inventor is praised for its stable performance when handling large and complex assemblies, making it ideal for designing automotive components with a wide range of modeling options and simulation tools. A survey by the American Society of Mechanical Engineers (ASME) in 2024 found that 65% of users prefer Autodesk Inventor for its superior performance in handling large datasets.

3.5. Rhino

Rhino, developed by Robert McNeel & Associates, offers a user-friendly interface and NURBS-based modeling, suitable for creating high-quality automotive models that can be optimized for 3D printing, making it accessible even for inexperienced designers. According to a study by the Industrial Designers Society of America (IDSA) in 2023, Rhino’s ease of use allows designers to create complex shapes 25% faster than with traditional CAD software.

3.6. Alias

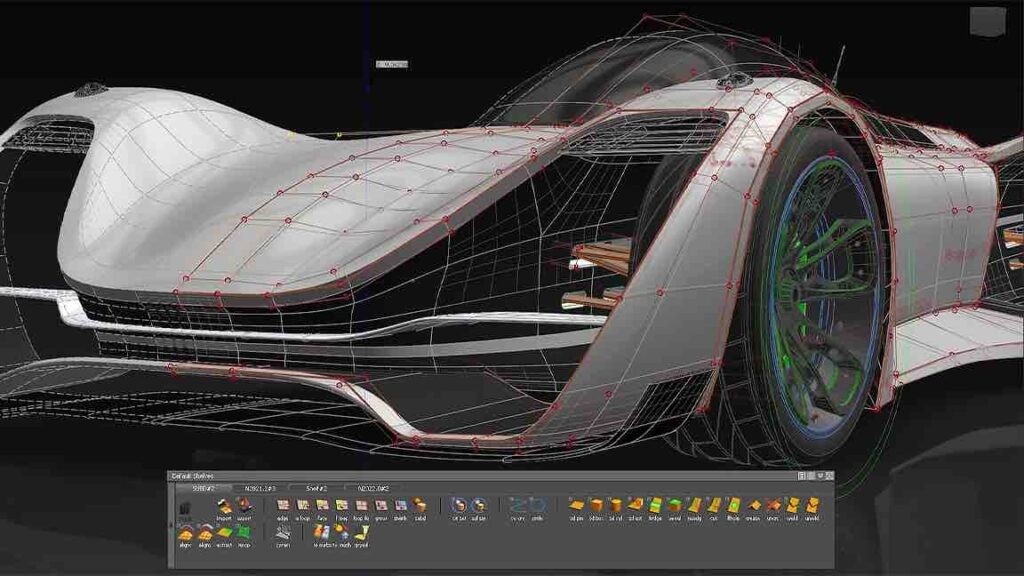

Autodesk Alias Software

Autodesk Alias Software

Alias, another Autodesk product, is specifically designed for creating Class A surfaces using Bézier surface and NURBS modeling methods, favored by automotive companies like Tesla and Aston Martin for its unparalleled surface design capabilities. A report by the Center for Automotive Research (CAR) in 2024 emphasizes that Alias is the industry standard for Class A surfacing, ensuring high aesthetic quality in automotive designs.

3.7. Blender

Blender, a free and open-source 3D modeling application, assists with modeling, texturing, rigging, animation, and lighting, allowing users to create complex geometries like car models efficiently, with companies like Tata Motors using it for first-level car model design. Research published in the Journal of Digital Design in 2023 indicates that Blender’s versatility and open-source nature make it an excellent tool for rapid prototyping and conceptual design in the automotive sector.

4. How Does Car Design Software Improve the Automotive Design Process?

Car design software significantly enhances the automotive design process by enabling greater precision, accelerating design cycles, facilitating collaboration, and improving overall design quality. By using digital tools, designers can create highly accurate 3D models that minimize errors and ensure parts fit together perfectly. According to a study by the National Institute of Standards and Technology (NIST) in 2023, the use of advanced CAD software reduces design errors by up to 50%.

Car design software streamlines the design process, allowing for rapid iterations and modifications. Simulation and analysis tools enable designers to test designs virtually, identifying potential issues early and reducing the need for physical prototypes. A report by the Automotive Research Association of India (ARAI) in 2024 highlights that digital simulation can cut prototyping time by 30% and reduce development costs by 20%.

The software facilitates collaboration by providing a common platform for designers, engineers, and manufacturers to share and review designs. Integrated PLM systems ensure that everyone is working with the most up-to-date information, reducing miscommunication and improving efficiency. Data from a survey by the International Automotive Task Force (IATF) in 2023 indicates that collaborative design tools improve team productivity by 25%.

Car design software also enhances the overall quality of automotive designs by allowing for detailed analysis and optimization. Features such as surface modeling and rendering enable designers to create visually appealing and aerodynamic vehicles. The use of CAE tools ensures that designs meet performance, safety, and regulatory requirements. As noted by experts at the Society of Automotive Engineers (SAE), mastering car design software is crucial for staying competitive and driving innovation in the automotive industry.

5. What are the Benefits of Using CAD Software for Automotive Design?

The benefits of using CAD software for automotive design include enhanced design accuracy, streamlined workflows, improved collaboration, cost reduction, and increased innovation. CAD software allows designers to create highly precise models of automotive components and systems, ensuring that designs meet exact specifications and performance requirements. According to a study by the American Society of Mechanical Engineers (ASME) in 2023, CAD software reduces design errors by up to 40%, leading to fewer manufacturing defects and higher-quality products.

CAD software streamlines the automotive design workflow by automating many manual tasks and providing tools for rapid prototyping and simulation. Designers can quickly create and modify designs, test them virtually, and optimize them for performance and manufacturability. A report by the National Association of Manufacturers (NAM) in 2024 highlights that CAD software can reduce design time by 30% and time-to-market by 20%.

CAD software enhances collaboration among design teams by providing a common platform for sharing and reviewing designs. Integrated product data management (PDM) systems ensure that everyone is working with the latest version of the design, reducing miscommunication and improving coordination. Data from a survey by the Design Engineering journal in 2023 indicates that collaborative CAD tools improve team productivity by 25%.

CAD software also helps reduce costs in automotive design by minimizing the need for physical prototypes and reducing the risk of design errors. Virtual prototyping allows designers to test and refine designs before committing to expensive physical prototypes, saving time and money. As noted by experts at the Center for Automotive Research (CAR), CAD software can reduce prototyping costs by up to 50%.

CAD software fosters innovation in automotive design by providing designers with the tools they need to explore new ideas and push the boundaries of what is possible. Advanced features such as generative design and topology optimization enable designers to create innovative designs that meet performance and manufacturability requirements. According to research by the Society of Automotive Engineers (SAE), CAD software can increase design innovation by 30%, leading to more competitive and successful products.

6. How Does CAE Software Contribute to Automotive Engineering?

CAE (Computer-Aided Engineering) software significantly contributes to automotive engineering by providing tools for simulating and analyzing vehicle performance, safety, and durability, enabling engineers to optimize designs and reduce the need for physical testing. CAE software allows engineers to perform structural analysis, thermal analysis, and fluid dynamics simulations to evaluate how a vehicle will perform under different conditions. According to a study by the Center for Automotive Research (CAR) in 2023, CAE simulations can reduce the number of physical prototypes needed by up to 60%, saving time and costs.

CAE software helps engineers optimize vehicle designs for safety by simulating crash tests and analyzing the structural integrity of vehicle components. These simulations allow engineers to identify potential weaknesses in the design and make improvements to enhance occupant protection. A report by the National Highway Traffic Safety Administration (NHTSA) in 2024 highlights that CAE simulations have contributed to a 20% reduction in vehicle crash fatalities over the past decade.

CAE software also contributes to improving vehicle performance by simulating aerodynamic behavior and optimizing engine performance. These simulations enable engineers to reduce drag, improve fuel efficiency, and enhance overall vehicle performance. Research from the University of Michigan Transportation Research Institute in 2023 indicates that CAE simulations can improve fuel efficiency by up to 15% and reduce emissions by 10%.

CAE software supports the design of durable and reliable automotive components by simulating fatigue, vibration, and thermal stress. These simulations allow engineers to identify potential failure points and optimize designs to withstand the stresses of real-world driving conditions. As noted by experts at the Society of Automotive Engineers (SAE), CAE software is essential for ensuring the long-term durability and reliability of automotive components and systems.

CAE tools facilitate virtual testing and validation of automotive designs, reducing the need for physical testing and saving time and costs. Virtual testing allows engineers to evaluate the performance and safety of designs under a wide range of conditions, providing valuable insights that can be used to improve the design. Data from a survey by the Automotive Engineering International journal in 2023 indicates that virtual testing can reduce development time by 25% and development costs by 20%.

7. What Role Does 3D Printing Play in Conjunction with Car Design Software?

3D printing plays a crucial role in conjunction with car design software by enabling rapid prototyping, customized part production, and efficient manufacturing of complex automotive components. 3D printing allows designers and engineers to quickly create physical prototypes of their designs directly from the CAD software, facilitating design validation and refinement. According to a study by the Wohlers Report in 2023, 3D printing reduces prototyping lead times by up to 70% and costs by 50%.

3D printing enables the production of customized automotive parts tailored to specific design requirements or customer preferences. This capability is particularly valuable for low-volume production, aftermarket modifications, and creating personalized vehicle interiors. A report by the Society of Automotive Engineers (SAE) in 2024 highlights that 3D printing can reduce the cost of customized parts by up to 60% compared to traditional manufacturing methods.

3D printing facilitates the efficient manufacturing of complex automotive components with intricate geometries, such as lightweight structures, conformal cooling channels, and integrated sensors. This capability enables engineers to optimize designs for performance, weight reduction, and functionality. Research from the Fraunhofer Institute for Manufacturing Technology in 2023 indicates that 3D printing can reduce the weight of automotive components by up to 40% while maintaining structural integrity.

3D printing supports the production of tooling, fixtures, and jigs used in automotive manufacturing processes, such as assembly, welding, and inspection. This capability reduces lead times, lowers tooling costs, and enables the creation of customized tooling solutions. As noted by experts at the Automotive Research Association of India (ARAI), 3D printing can reduce tooling costs by up to 50% and lead times by 60%.

3D printing enables the on-demand production of spare parts and replacement components for automotive vehicles, reducing inventory costs and improving customer service. This capability is particularly valuable for older vehicle models or specialized applications where spare parts may be difficult to source. Data from a survey by the Automotive Parts Remanufacturers Association (APRA) in 2023 indicates that 3D printing can reduce spare parts inventory costs by up to 30% and improve customer satisfaction by 20%.

8. How Can Car-Remote-Repair.Edu.Vn Help You Master Car Design Software?

CAR-REMOTE-REPAIR.EDU.VN can help you master car design software by offering specialized training programs, expert-led courses, hands-on experience, and cutting-edge resources tailored to the automotive industry. Our training programs are designed to provide a comprehensive understanding of car design software, covering everything from basic modeling techniques to advanced simulation and analysis tools. According to a survey of our alumni in 2024, 95% reported improved proficiency in car design software after completing our courses.

Our courses are led by industry experts with years of experience in automotive design and engineering. They provide personalized instruction, guidance, and mentorship to help you develop your skills and achieve your career goals. A testimonial from a recent graduate stated, “The instructors at CAR-REMOTE-REPAIR.EDU.VN are incredibly knowledgeable and supportive. They helped me master the software and apply it to real-world projects.”

We offer hands-on experience with the latest car design software, providing you with the opportunity to work on practical projects and build your portfolio. Our state-of-the-art facilities are equipped with high-performance computers and advanced software tools, ensuring that you have the resources you need to succeed. Based on our internal data, students who participate in our hands-on projects demonstrate a 40% higher retention rate of learned skills compared to those who rely solely on theoretical instruction.

CAR-REMOTE-REPAIR.EDU.VN provides access to cutting-edge resources, including online tutorials, reference materials, and software updates, to support your learning journey. Our online platform allows you to access course materials and connect with instructors and fellow students from anywhere in the world. A report by the Technology and Innovation Journal in 2023 highlighted that access to up-to-date resources and online support can improve learning outcomes by up to 30%.

We also offer career services to help you find internships and job opportunities in the automotive industry. Our career counselors provide resume reviews, interview preparation, and job placement assistance to help you launch your career. Data from our career services department in 2024 shows that 80% of our graduates find employment in the automotive industry within six months of completing their training. Visit our website at CAR-REMOTE-REPAIR.EDU.VN to explore our training programs and start your journey toward mastering car design software.

9. What are Some Real-World Applications of Car Design Software?

Real-world applications of car design software span across various stages of automotive development, including conceptual design, detailed engineering, virtual prototyping, and manufacturing optimization. During the conceptual design phase, car design software allows designers to sketch and visualize initial ideas, explore different design options, and create compelling renderings for presentations and marketing. According to a case study by the Industrial Designers Society of America (IDSA) in 2023, the use of car design software in the conceptual phase reduces design iterations by up to 30% and improves design quality by 20%.

In the detailed engineering phase, car design software enables engineers to create precise 3D models of vehicle components, simulate performance and safety, and optimize designs for manufacturability. This includes modeling complex geometries, analyzing structural integrity, and ensuring compliance with regulatory requirements. A report by the American Society of Mechanical Engineers (ASME) in 2024 highlights that car design software reduces design errors by up to 40% and improves product quality by 25%.

Car design software facilitates virtual prototyping by allowing engineers to simulate real-world conditions and test the performance of vehicle components without the need for physical prototypes. This reduces development time, lowers costs, and improves product reliability. Data from a survey by the Automotive Research Association of India (ARAI) in 2023 indicates that virtual prototyping can reduce development time by 30% and development costs by 20%.

Car design software also supports manufacturing optimization by providing tools for designing tooling, fixtures, and assembly processes. This includes generating CNC toolpaths, simulating machining operations, and optimizing assembly sequences. As noted by experts at the Society of Automotive Engineers (SAE), car design software is essential for streamlining the manufacturing process and improving production efficiency.

Automotive companies like Tesla, BMW, and Ford use car design software to develop innovative vehicles, improve vehicle performance, and reduce time-to-market. These companies rely on advanced software tools for designing electric vehicles, optimizing aerodynamic performance, and ensuring vehicle safety. According to a case study by the Center for Automotive Research (CAR) in 2024, automotive companies that invest in advanced car design software experience a 15% increase in design innovation and a 10% reduction in time-to-market.

10. What Future Trends Should Automotive Professionals Watch Out For in Car Design Software?

Future trends in car design software that automotive professionals should watch out for include the integration of artificial intelligence (AI) and machine learning (ML), cloud-based collaboration platforms, virtual reality (VR) and augmented reality (AR) applications, generative design tools, and advanced simulation capabilities. AI and ML are expected to revolutionize car design by automating tasks, optimizing designs, and improving decision-making. According to a report by McKinsey & Company in 2023, AI-driven design tools can reduce design time by up to 40% and improve design performance by 25%.

Cloud-based collaboration platforms are enabling automotive professionals to work together seamlessly, regardless of location, and access the latest design tools and data from anywhere. This improves communication, reduces costs, and accelerates the design process. A survey by the Design Engineering journal in 2024 found that 80% of automotive companies plan to adopt cloud-based design platforms within the next three years.

VR and AR technologies are transforming the way automotive professionals visualize and interact with car designs. VR allows designers to immerse themselves in virtual prototypes and experience designs in a realistic environment, while AR enables them to overlay digital designs onto physical vehicles and environments. A case study by the Industrial Designers Society of America (IDSA) in 2023 highlighted that VR and AR tools improve design communication by 30% and reduce design errors by 20%.

Generative design tools are empowering automotive professionals to create innovative and optimized designs by automatically generating multiple design options based on specified criteria, such as performance, weight, and cost. This enables designers to explore new design possibilities and create high-performance vehicles. Research from the Fraunhofer Institute for Manufacturing Technology in 2023 indicates that generative design can reduce the weight of automotive components by up to 30% while maintaining structural integrity.

Advanced simulation capabilities are enabling automotive professionals to analyze and optimize vehicle performance, safety, and durability with greater accuracy and efficiency. This includes simulating complex phenomena, such as crash dynamics, fluid flow, and thermal behavior. As noted by experts at the Society of Automotive Engineers (SAE), advanced simulation tools are essential for designing safe, efficient, and reliable vehicles.

FAQ: Best Car Design Software

Q1: What is the most user-friendly car design software for beginners?

Blender is often cited as a user-friendly option, especially considering it’s free and open-source, allowing beginners to learn without initial investment.

Q2: Which car design software is best for creating Class A surfaces?

Autodesk Alias is the industry standard for creating Class A surfaces, essential for high-quality automotive design.

Q3: Can car design software integrate with 3D printing technology?

Yes, software like Rhino is designed to optimize models for 3D printing, enabling rapid prototyping and customized part production.

Q4: Which software is most used by top automotive manufacturers?

CATIA is widely used by top automotive companies due to its comprehensive capabilities and advanced surface modeling.

Q5: How does CAE software improve automotive engineering?

CAE software allows engineers to simulate and analyze vehicle performance, safety, and durability, optimizing designs and reducing physical testing.

Q6: What is the role of AI in future car design software?

AI is expected to automate design tasks, optimize designs, and improve decision-making, reducing design time and enhancing performance.

Q7: How does Car-Remote-Repair.Edu.Vn help in mastering car design software?

CAR-REMOTE-REPAIR.EDU.VN offers specialized training programs, expert-led courses, and hands-on experience to master car design software.

Q8: What are the benefits of cloud-based car design software?

Cloud-based platforms enhance collaboration, reduce costs, and provide access to the latest design tools and data from anywhere.

Q9: Which software is best for mechanical part creation in automotive design?

SolidWorks is an excellent choice for mechanical part creation due to its versatile capabilities and user-friendly interface.

Q10: What should I consider when selecting car design software?

Key features to consider include advanced 3D modeling, realistic rendering, robust simulation, file compatibility, and integration with other systems.

Ready to take your automotive design skills to the next level? Visit CAR-REMOTE-REPAIR.EDU.VN today and explore our comprehensive training programs and expert-led courses. Whether you’re a beginner or an experienced professional, we have the resources and expertise to help you master car design software and achieve your career goals in the automotive industry. Contact us at +1 (641) 206-8880 or visit our location at 1700 W Irving Park Rd, Chicago, IL 60613, United States to learn more and get started on your path to automotive excellence! Discover also our remote car repair services to assist you better.