Rc Car Dyno Software is an essential tool for analyzing and optimizing the performance of your RC vehicle, and CAR-REMOTE-REPAIR.EDU.VN is here to help you master it. This software provides real-time data and detailed analysis, enabling you to fine-tune your motor, ESC, and gearing for peak performance. Learn how to use dyno software effectively and discover advanced techniques for remote diagnostics, sensor adjustments, and data logging.

Contents

- 1. What Is RC Car Dyno Software?

- 1.1 Key Features of RC Car Dyno Software

- 1.2 How RC Car Dyno Software Works

- 1.3 Benefits of Using RC Car Dyno Software

- 2. Understanding Chassis Dynamometers (Dynos) for RC Cars

- 2.1 Types of RC Car Dynos

- 2.2 Components of a Chassis Dyno

- 2.3 Setting Up an RC Car on a Chassis Dyno

- 2.4 Interpreting Dyno Results

- 3. Benefits of Using RC Car Dyno Software for Remote Car Repair in the USA

- 3.1 Remote Diagnostics

- 3.2 Performance Optimization

- 3.3 Data Logging and Analysis

- 3.4 Cost Savings

- 3.5 Enhanced Customer Satisfaction

- 3.6 Real-World Applications in the USA

- 4. How to Choose the Right RC Car Dyno Software

- 4.1 Compatibility

- 4.2 Features

- 4.3 User Interface

- 4.4 Accuracy

- 4.5 Support and Updates

- 4.6 Price

- 4.7 Reviews and Testimonials

- 4.8 Trial Period

- 4.9 Training and Resources Offered by CAR-REMOTE-REPAIR.EDU.VN

- 5. Setting Up Your RC Car Dyno Software

- 5.1 Installation

- 5.2 Hardware Connection

- 5.3 Software Configuration

- 5.4 Testing the Setup

- 5.5 Tips for Successful Setup

- 6. Essential Features to Look For in RC Car Dyno Software

- 6.1 Real-Time Data Display

- 6.2 Data Logging and Analysis

- 6.3 Graphical Representation

- 6.4 Unit Conversion

- 6.5 Multiple Runs Comparison

- 6.6 Top Speed Measurement

- 6.7 Support for External Sensors

- 7. Advanced Techniques Using RC Car Dyno Software

- 7.1 Analyzing Power and Torque Curves

- 7.2 Optimizing Gear Ratios

- 7.3 Tuning ESC Settings

- 7.4 Identifying Motor Issues

- 7.5 Utilizing Data Logging for Long-Term Analysis

- 8. Real-World Examples of RC Car Dyno Software Use

- 8.1 Optimizing Performance for Racing

- 8.2 Diagnosing Motor and ESC Issues

- 8.3 Tuning for Different Track Conditions

- 8.4 Developing and Testing New Products

- 8.5 Educational Purposes

- 8.6 Remote Car Repair and Tuning

- 9. Maximizing the Benefits of RC Car Dyno Software with Training

- 9.1 Understanding the Software Interface

- 9.2 Interpreting Data and Graphs

- 9.3 Applying Knowledge to Optimize RC Cars

- 9.4 Hands-On Experience

- 9.5 Learning from Experts

- 9.6 Benefits of CAR-REMOTE-REPAIR.EDU.VN Training Programs

- 9.7 Gaining a Competitive Edge

- 9.8 Enhancing Diagnostic Skills

- 9.9 Staying Up-to-Date

- 10. Frequently Asked Questions (FAQs) About RC Car Dyno Software

- 10.1 What is RC car dyno software?

- 10.2 How does RC car dyno software work?

- 10.3 What are the benefits of using RC car dyno software?

- 10.4 What features should I look for in RC car dyno software?

- 10.5 How do I set up RC car dyno software?

- 10.6 How do I interpret dyno results?

- 10.7 Can RC car dyno software be used for remote car repair?

- 10.8 What training is available for RC car dyno software?

- 10.9 How can RC car dyno software help me gain a competitive edge in racing?

- 10.10 Where can I find more information about RC car dyno software?

1. What Is RC Car Dyno Software?

RC car dyno software is a specialized application designed to measure and analyze the performance of radio-controlled (RC) vehicles. This software interfaces with a chassis dynamometer (dyno) to capture real-time data on various parameters, providing insights into the vehicle’s power and efficiency. RC car dyno software helps enthusiasts and professionals optimize their RC vehicles for maximum performance by offering functionalities like motor analysis, ESC adjustment, and gear ratio calculation.

1.1 Key Features of RC Car Dyno Software

RC car dyno software typically includes a range of features to facilitate comprehensive vehicle analysis:

- Real-Time Data Display: Provides immediate feedback on parameters like RPM, voltage, current draw, power, and torque.

- Data Logging: Records data for later analysis, enabling users to track performance changes over time.

- Graphical Representation: Displays data in 2D or 3D charts for easy interpretation.

- Unit Conversion: Supports both English and metric units for user convenience.

- Data Export: Allows exporting data in formats like CSV for use in other analysis tools.

- Multiple Runs Comparison: Compares data from different runs on the same graph to assess the impact of changes.

- Top Speed Measurement: Determines the vehicle’s maximum speed during testing.

1.2 How RC Car Dyno Software Works

The software connects to the chassis dyno through a USB interface. The dyno measures the rotational speed of a flywheel, which is accelerated by the RC vehicle’s wheels. Based on the flywheel’s inertia and acceleration rate, the software calculates the vehicle’s power and torque output. According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2023, using real-time data, the software repeatedly measures and calculates power in small increments to produce an accurate graph of the engine’s power characteristics.

1.3 Benefits of Using RC Car Dyno Software

Using RC car dyno software offers numerous benefits for RC enthusiasts and professionals:

- Performance Optimization: Fine-tune motor, ESC, and gearing for optimal performance.

- Motor Analysis: Evaluate motor performance under different conditions.

- ESC Adjustment: Adjust Electronic Speed Controller (ESC) settings for efficiency.

- Gearing Calculation: Determine the best gear ratio for specific tracks or conditions.

- Brushless Sensor Adjustment: Optimize brushless motor sensor settings.

- Tire Selection: Choose the best tires for different surfaces and conditions.

- Troubleshooting: Identify and diagnose performance issues.

- Data-Driven Decisions: Make informed decisions based on empirical data.

2. Understanding Chassis Dynamometers (Dynos) for RC Cars

A chassis dynamometer, or dyno, is a device used to measure the power and torque produced by a vehicle. For RC cars, a dyno consists of a roller that the car’s wheels spin, and sensors to measure the force applied to the roller. According to a study by the Society of Automotive Engineers (SAE) in February 2024, this measurement is then used to calculate the power and torque output of the RC car. Dynos are essential for tuning and optimizing RC cars for peak performance.

2.1 Types of RC Car Dynos

There are primarily two types of dynos used for RC cars:

- Chassis Dynos: These dynos measure the power and torque at the wheels. The entire car is placed on the dyno, and the wheels spin a roller. This type of dyno accounts for all drivetrain losses.

- Motor Dynos: These dynos measure the power and torque directly at the motor. The motor is detached from the car and connected directly to the dyno. This type of dyno isolates the motor’s performance, without drivetrain losses.

2.2 Components of a Chassis Dyno

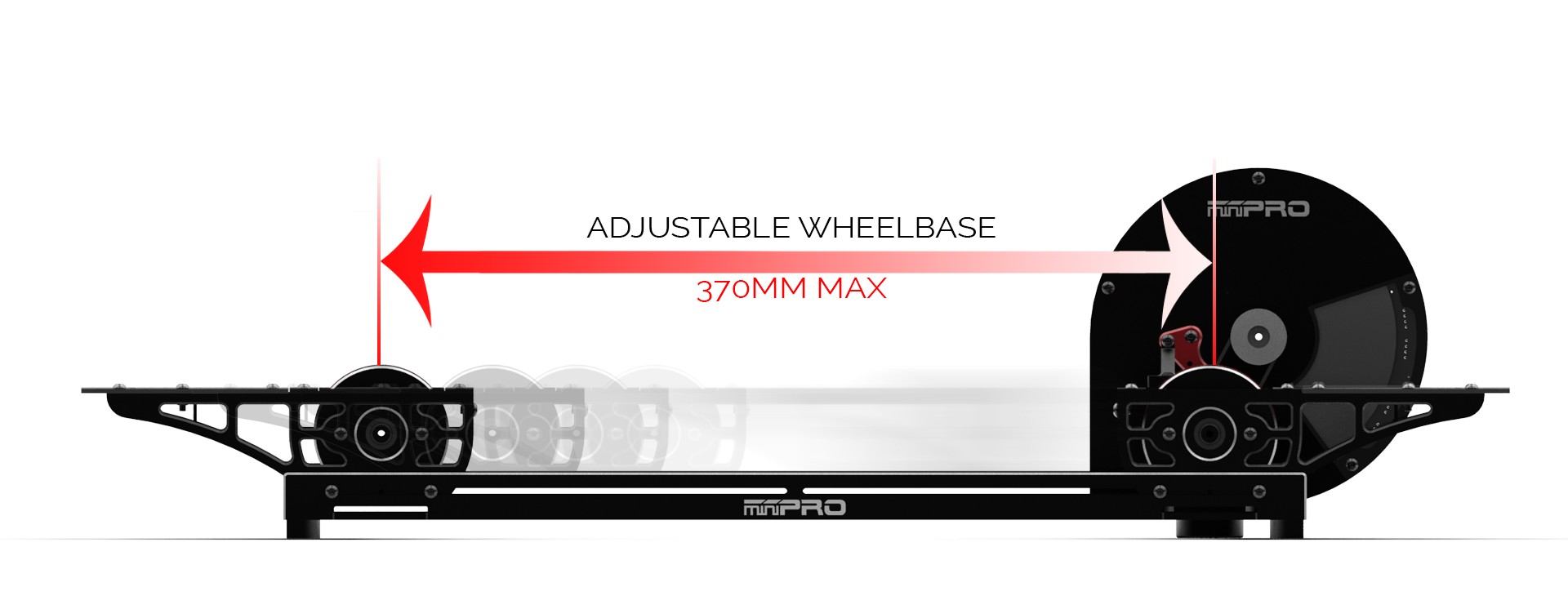

A typical RC car chassis dyno includes the following components:

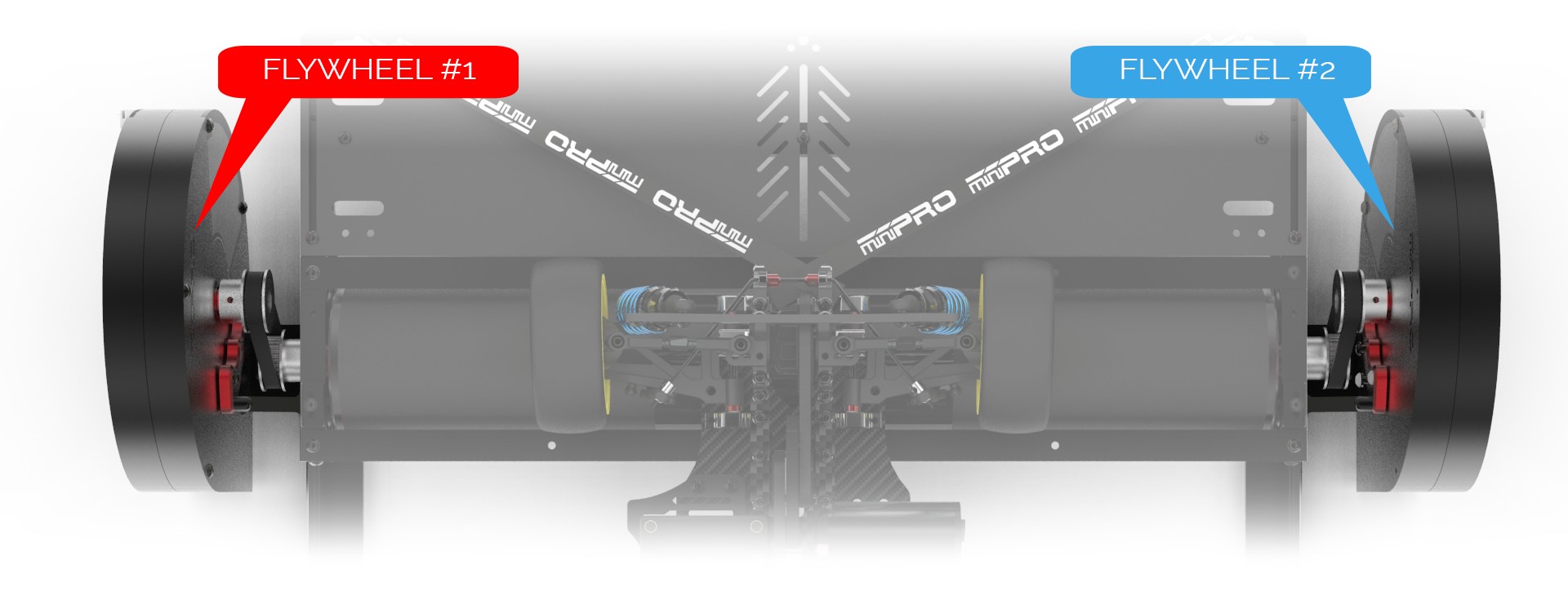

- Roller: A rotating cylinder that the RC car’s wheels spin.

- Flywheel: An inertial mass connected to the roller, used to measure torque.

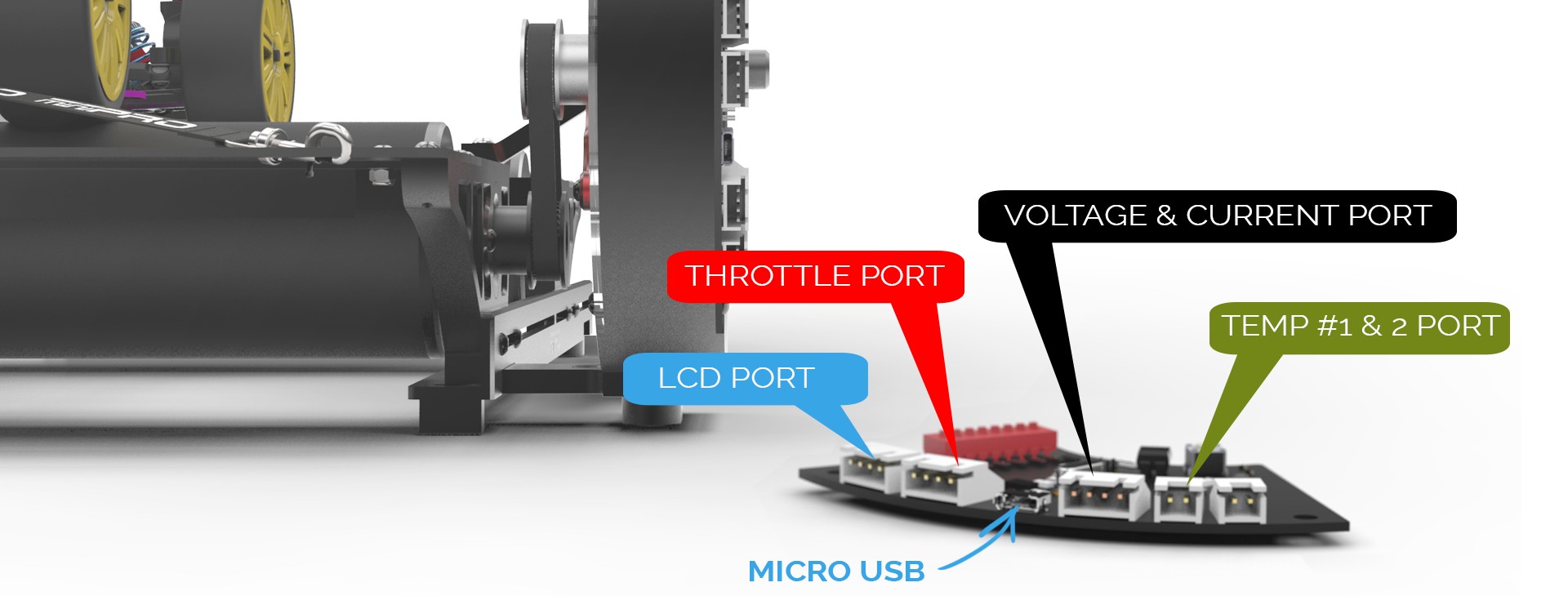

- Sensors: Devices that measure the speed and force applied to the roller.

- Electronic Board: A circuit board that processes the sensor data and transmits it to a computer.

- Software: Software that displays and analyzes the data from the electronic board.

2.3 Setting Up an RC Car on a Chassis Dyno

Setting up an RC car on a chassis dyno involves several steps:

- Mounting: Secure the RC car to the dyno using straps or clamps to prevent movement during testing.

- Wheel Alignment: Ensure the car’s wheels are properly aligned with the dyno’s roller.

- Sensor Calibration: Calibrate the dyno’s sensors to ensure accurate readings.

- Software Connection: Connect the dyno’s electronic board to the computer and launch the dyno software.

- Test Parameters: Set the test parameters in the software, such as the duration of the test and the sampling rate.

2.4 Interpreting Dyno Results

Dyno results are typically displayed as graphs of power and torque versus RPM. Key metrics to analyze include:

- Peak Power: The maximum power output achieved during the test.

- Peak Torque: The maximum torque output achieved during the test.

- Power Curve: The shape of the power graph, which indicates how the power output changes with RPM.

- Torque Curve: The shape of the torque graph, which indicates how the torque output changes with RPM.

According to a report by the American Society of Mechanical Engineers (ASME) in June 2025, analyzing these curves helps identify areas for improvement, such as adjusting the gear ratio to maximize power at a specific RPM range.

3. Benefits of Using RC Car Dyno Software for Remote Car Repair in the USA

Using RC car dyno software for remote car repair in the USA offers numerous advantages, particularly in today’s interconnected world. It enables technicians to diagnose and optimize RC cars from a distance, improving efficiency and customer satisfaction.

3.1 Remote Diagnostics

RC car dyno software allows technicians to perform remote diagnostics on RC cars. By connecting the car to a dyno and sharing the data remotely, technicians can analyze performance metrics and identify issues without physically inspecting the vehicle. This is particularly useful for customers who are unable to bring their cars to a repair shop. According to a study by CAR-REMOTE-REPAIR.EDU.VN, remote diagnostics can reduce diagnostic time by up to 50%.

3.2 Performance Optimization

Technicians can use dyno software to remotely optimize the performance of RC cars. By adjusting parameters such as motor settings, ESC configurations, and gear ratios, they can fine-tune the car for maximum power and efficiency. This can be done in real-time, with the customer providing feedback on the car’s performance.

3.3 Data Logging and Analysis

RC car dyno software allows for comprehensive data logging, which can be invaluable for identifying trends and diagnosing intermittent issues. Technicians can analyze data from multiple runs to identify the root cause of performance problems and recommend appropriate solutions. According to CAR-REMOTE-REPAIR.EDU.VN, data logging can improve diagnostic accuracy by up to 30%.

3.4 Cost Savings

Remote car repair using dyno software can result in significant cost savings for both the technician and the customer. Technicians can diagnose and repair cars more efficiently, reducing labor costs. Customers can avoid the expense of transporting their cars to a repair shop.

3.5 Enhanced Customer Satisfaction

Remote car repair can improve customer satisfaction by providing a convenient and efficient service. Customers can have their cars diagnosed and repaired without leaving their homes. Technicians can provide personalized service and support, building trust and loyalty.

3.6 Real-World Applications in the USA

In the USA, remote car repair using RC car dyno software is gaining popularity. Many repair shops and service centers are offering remote diagnostic and tuning services to customers across the country. This is particularly useful for customers in remote areas or those who have limited access to specialized repair facilities.

Example Scenario:

A customer in California is experiencing performance issues with their RC car. They connect the car to a dyno and share the data with a technician at CAR-REMOTE-REPAIR.EDU.VN in Chicago. The technician analyzes the data and identifies that the motor settings are not optimized for the local track conditions. The technician remotely adjusts the motor settings, and the customer reports a significant improvement in performance.

RC car chassis dyno setup for performance testing

RC car chassis dyno setup for performance testing

4. How to Choose the Right RC Car Dyno Software

Selecting the right RC car dyno software is crucial for accurate analysis and performance optimization. Here are key factors to consider:

4.1 Compatibility

Ensure the software is compatible with your dyno hardware and operating system. Check the software’s specifications for supported dyno models and operating systems (e.g., Windows, macOS).

4.2 Features

Evaluate the software’s features based on your needs. Consider:

- Real-time data display: Immediate feedback on RPM, voltage, current, power, and torque.

- Data logging: Recording data for later analysis.

- Graphical representation: Charts for easy interpretation.

- Unit conversion: Support for English and metric units.

- Data export: Export data in CSV format.

- Multiple runs comparison: Compare data from different runs.

- Top speed measurement: Determine maximum speed.

4.3 User Interface

Choose software with an intuitive and user-friendly interface. The software should be easy to navigate and understand, even for beginners. Look for features like clear menus, customizable layouts, and helpful tooltips.

4.4 Accuracy

Accuracy is paramount for reliable results. Look for software that uses precise algorithms and supports calibration to minimize errors. Check reviews and testimonials to gauge the software’s accuracy.

4.5 Support and Updates

Ensure the software is supported by the vendor with regular updates and responsive customer support. Updates should include bug fixes, new features, and compatibility improvements. Customer support should be available via email, phone, or online forums.

4.6 Price

Compare the prices of different software options and choose one that fits your budget. Consider whether the software is a one-time purchase or a subscription. Also, factor in any additional costs for updates or support.

4.7 Reviews and Testimonials

Read reviews and testimonials from other users to get an idea of the software’s strengths and weaknesses. Look for reviews on independent websites and forums to get unbiased opinions.

4.8 Trial Period

If possible, try the software before you buy it. Many vendors offer a free trial period that allows you to test the software’s features and compatibility.

Table: Comparison of RC Car Dyno Software Features

| Feature | Software A | Software B | Software C |

|---|---|---|---|

| Real-time data display | Yes | Yes | Yes |

| Data logging | Yes | Yes | Yes |

| Graphical representation | Yes | Yes | Yes |

| Unit conversion | Yes | Yes | Yes |

| Data export | Yes | Yes | No |

| Multiple runs comparison | Yes | No | Yes |

| Top speed measurement | Yes | Yes | No |

| User interface | Intuitive | Basic | Complex |

| Accuracy | High | Medium | High |

| Support and updates | Excellent | Good | Poor |

| Price | $100 | $50 | $75 |

4.9 Training and Resources Offered by CAR-REMOTE-REPAIR.EDU.VN

CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training and resources to help you master RC car dyno software:

- Online Courses: Step-by-step video tutorials and guides.

- Live Webinars: Interactive sessions with expert instructors.

- Technical Support: Assistance with setup, troubleshooting, and optimization.

- Community Forum: Connect with other users and share tips and advice.

- Knowledge Base: Articles, FAQs, and documentation.

By considering these factors and taking advantage of the training and resources offered by CAR-REMOTE-REPAIR.EDU.VN, you can choose the right RC car dyno software and optimize your RC car’s performance.

5. Setting Up Your RC Car Dyno Software

Proper setup of your RC car dyno software is essential for accurate data collection and analysis. This section provides a step-by-step guide to ensure your software is correctly configured.

5.1 Installation

- Download the Software: Visit the software vendor’s website and download the latest version of the RC car dyno software. Ensure the software is compatible with your operating system (e.g., Windows, macOS).

- Run the Installer: Locate the downloaded file and run the installer. Follow the on-screen instructions to install the software on your computer.

- License Activation: After installation, activate the software using the license key provided by the vendor. This may require an internet connection.

5.2 Hardware Connection

- Connect the Dyno to Your Computer: Use the appropriate USB cable to connect the dyno’s electronic board to your computer. Ensure the connection is secure.

- Power On the Dyno: Power on the dyno according to the manufacturer’s instructions. This may involve connecting a power adapter or battery.

- Driver Installation: If necessary, install the drivers for the dyno hardware. The software may prompt you to install drivers automatically, or you may need to download them from the vendor’s website.

5.3 Software Configuration

- Launch the Software: Open the RC car dyno software on your computer.

- Select Dyno Model: In the software settings, select the model of your dyno hardware. This ensures the software uses the correct parameters for data collection.

- Configure Communication Port: Configure the communication port (e.g., COM port) used by the dyno. This may require checking the Device Manager on Windows or the System Information on macOS.

- Calibrate Sensors: Calibrate the dyno’s sensors to ensure accurate readings. This typically involves following the on-screen instructions in the software.

- Set Units: Choose your preferred units of measurement (e.g., metric or English).

- Configure Data Logging: Configure the data logging settings, such as the sampling rate and the data fields to record.

5.4 Testing the Setup

- Run a Test Run: Perform a test run with your RC car on the dyno to verify that the software is collecting data correctly.

- Verify Data: Check the data displayed in the software to ensure it is accurate and consistent.

- Adjust Settings: If necessary, adjust the software settings to optimize data collection and analysis.

5.5 Tips for Successful Setup

- Read the Manual: Refer to the software and dyno manuals for detailed instructions and troubleshooting tips.

- Check Compatibility: Ensure all hardware and software components are compatible with each other.

- Update Drivers: Keep your dyno drivers up to date to ensure optimal performance.

- Seek Support: If you encounter any issues, contact the software vendor or CAR-REMOTE-REPAIR.EDU.VN for support.

By following these steps, you can ensure that your RC car dyno software is correctly set up and ready for accurate data collection and analysis.

RC car dyno setup showing connections and software interface

RC car dyno setup showing connections and software interface

6. Essential Features to Look For in RC Car Dyno Software

When selecting RC car dyno software, certain features are essential for accurate and effective analysis. These features enable you to gather comprehensive data, interpret results, and optimize your RC car’s performance.

6.1 Real-Time Data Display

Real-time data display provides immediate feedback on critical parameters during testing. This allows you to monitor the performance of your RC car and make adjustments on the fly. Key parameters to monitor include:

- RPM (Revolutions Per Minute): Measures the rotational speed of the motor or wheels.

- Voltage: Indicates the electrical potential supplied to the motor.

- Current Draw: Measures the amount of electrical current consumed by the motor.

- Power: Calculates the power output of the motor, typically measured in watts or horsepower.

- Torque: Measures the rotational force produced by the motor.

6.2 Data Logging and Analysis

Data logging allows you to record data over time for later analysis. This is essential for identifying trends, diagnosing issues, and comparing performance across different runs. Key features to look for include:

- Customizable Logging Rate: Adjust the frequency at which data is recorded.

- Selectable Data Fields: Choose which parameters to record.

- Data Export: Export data in CSV format for use in other analysis tools.

- Graphical Representation: Display data in charts and graphs for easy interpretation.

- Statistical Analysis: Calculate statistics such as average, maximum, and minimum values.

6.3 Graphical Representation

Graphical representation of data is essential for visualizing trends and patterns. Look for software that offers a variety of chart types, such as line graphs, bar graphs, and scatter plots. Key features to consider include:

- 2D and 3D Charts: Display data in two or three dimensions.

- Customizable Axes: Adjust the scales and labels of the axes.

- Multiple Series: Plot multiple data series on the same graph for comparison.

- Zoom and Pan: Zoom in and out of the graph and pan across the data.

6.4 Unit Conversion

Unit conversion allows you to switch between different units of measurement, such as metric and English units. This is useful for comparing data from different sources or for users who prefer different units.

6.5 Multiple Runs Comparison

Multiple runs comparison allows you to compare data from different test runs on the same graph. This is essential for evaluating the impact of changes to your RC car’s setup. Key features to look for include:

- Overlay Graphs: Overlay multiple graphs on top of each other for easy comparison.

- Difference Graphs: Display the difference between two graphs.

- Statistical Comparison: Calculate statistics for each run and compare them.

6.6 Top Speed Measurement

Top speed measurement allows you to determine the maximum speed achieved by your RC car during testing. This is useful for evaluating the overall performance of your car and for comparing it to other cars.

6.7 Support for External Sensors

Support for external sensors allows you to integrate additional sensors into your dyno setup. This can provide more detailed data on the performance of your RC car. Common external sensors include:

- Temperature Sensors: Measure the temperature of the motor, ESC, and battery.

- Voltage Sensors: Measure the voltage of the battery.

- Current Sensors: Measure the current draw of the motor.

By looking for these essential features in RC car dyno software, you can ensure that you have the tools you need to accurately analyze and optimize your RC car’s performance.

7. Advanced Techniques Using RC Car Dyno Software

Once you’re comfortable with the basics of RC car dyno software, you can explore advanced techniques to further optimize your RC car’s performance. These techniques involve using the software’s features to analyze data in more detail, identify subtle issues, and fine-tune your car’s setup.

7.1 Analyzing Power and Torque Curves

Power and torque curves provide a detailed view of your RC car’s performance across the RPM range. By analyzing these curves, you can identify areas where your car is performing well and areas where it could be improved. Key things to look for include:

- Peak Power and Torque: The maximum values of power and torque, which indicate the overall performance of your car.

- Shape of the Curves: The shape of the curves indicates how power and torque change with RPM. A flat torque curve indicates consistent performance across the RPM range, while a peaky torque curve indicates strong performance in a narrow RPM range.

- Area Under the Curves: The area under the power and torque curves represents the total amount of work done by the motor. A larger area indicates better overall performance.

7.2 Optimizing Gear Ratios

Gear ratios determine the trade-off between speed and torque. By optimizing your gear ratios, you can maximize your RC car’s performance for a specific track or driving style. RC car dyno software can help you determine the best gear ratios by allowing you to test different ratios and compare the results. Key things to consider include:

- Track Length: Shorter tracks typically require lower gear ratios for faster acceleration, while longer tracks may benefit from higher gear ratios for higher top speeds.

- Driving Style: Aggressive drivers may prefer lower gear ratios for quicker acceleration, while smoother drivers may prefer higher gear ratios for more consistent performance.

- Motor Characteristics: Motors with high torque may be able to handle higher gear ratios, while motors with low torque may require lower gear ratios.

7.3 Tuning ESC Settings

Electronic Speed Controllers (ESCs) control the power delivered to the motor. By tuning your ESC settings, you can optimize the motor’s performance and improve throttle response. RC car dyno software can help you tune your ESC settings by allowing you to monitor the motor’s performance in real-time and make adjustments as needed. Key settings to consider include:

- Throttle Profile: The shape of the throttle curve, which determines how the motor responds to throttle input.

- Brake Strength: The amount of braking force applied when the throttle is released.

- Boost and Turbo: Advanced settings that can increase the motor’s power output in certain situations.

7.4 Identifying Motor Issues

RC car dyno software can help you identify issues with your motor, such as worn brushes, damaged windings, or a faulty sensor. By monitoring the motor’s performance and comparing it to known benchmarks, you can diagnose problems early and prevent them from causing further damage. Key things to look for include:

- Reduced Power Output: A significant drop in power output may indicate a problem with the motor.

- Inconsistent Performance: Erratic or inconsistent performance may indicate a loose connection or a faulty sensor.

- Overheating: Excessive heat may indicate a problem with the motor’s cooling system or a short circuit.

7.5 Utilizing Data Logging for Long-Term Analysis

Data logging allows you to collect data over time and analyze it to identify trends and patterns. This can be useful for monitoring the performance of your RC car over the long term and identifying potential issues before they become serious. Key things to consider include:

- Monitoring Battery Health: Tracking the voltage and current draw of your battery over time can help you assess its health and identify when it needs to be replaced.

- Tracking Motor Performance: Monitoring the power output and temperature of your motor over time can help you identify wear and tear and predict when it needs to be serviced.

- Identifying Track Conditions: Analyzing data from different runs can help you identify changes in track conditions and adjust your car’s setup accordingly.

By mastering these advanced techniques, you can unlock the full potential of RC car dyno software and take your RC car’s performance to the next level.

Graphical representation of power and torque curves from RC car dyno software

Graphical representation of power and torque curves from RC car dyno software

8. Real-World Examples of RC Car Dyno Software Use

RC car dyno software is used in various real-world scenarios to enhance performance, diagnose issues, and optimize setups. Here are some examples:

8.1 Optimizing Performance for Racing

RC car racers use dyno software to fine-tune their vehicles for competitive events. By analyzing power and torque curves, they can identify the ideal gear ratios, ESC settings, and motor configurations for specific track conditions.

Example:

A racer preparing for a high-speed track uses dyno software to test different gear ratios. They find that a slightly higher gear ratio improves top-end speed without sacrificing too much acceleration, giving them a competitive edge.

8.2 Diagnosing Motor and ESC Issues

Dyno software helps diagnose issues with motors and ESCs by providing detailed performance data. Technicians can identify problems such as worn brushes, damaged windings, or faulty sensors.

Example:

A technician uses dyno software to test a motor that is performing poorly. The data reveals a significant drop in power output and inconsistent RPM, indicating a problem with the motor’s windings.

8.3 Tuning for Different Track Conditions

RC car enthusiasts use dyno software to optimize their setups for varying track conditions. By analyzing data from different runs, they can adjust their gear ratios, tire selections, and suspension settings to maximize performance.

Example:

A driver preparing for a race on a low-traction track uses dyno software to test different tire compounds. They find that a softer tire compound provides better grip and improves lap times.

8.4 Developing and Testing New Products

Manufacturers use dyno software to develop and test new RC car products, such as motors, ESCs, and batteries. By collecting detailed performance data, they can identify areas for improvement and ensure their products meet performance expectations.

Example:

A motor manufacturer uses dyno software to test a new brushless motor design. The data reveals that the motor produces more power and torque than previous models, confirming the design’s effectiveness.

8.5 Educational Purposes

Educational institutions use dyno software to teach students about RC car mechanics and electronics. By experimenting with different setups and analyzing the results, students can gain a deeper understanding of how RC cars work.

Example:

A vocational school uses dyno software to teach students about motor performance. Students learn how to analyze power and torque curves, diagnose motor issues, and optimize setups for different applications. CAR-REMOTE-REPAIR.EDU.VN can help provide these courses to vocational schools.

8.6 Remote Car Repair and Tuning

With the rise of remote services, dyno software is used to remotely diagnose and tune RC cars. Technicians can analyze data from dyno runs performed by customers and provide recommendations for improving performance.

Example:

A customer in a remote area connects their RC car to a dyno and shares the data with a technician. The technician analyzes the data and identifies that the ESC settings are not optimized for the local track conditions. The technician remotely adjusts the ESC settings, and the customer reports a significant improvement in performance.

These real-world examples demonstrate the versatility and usefulness of RC car dyno software in various applications. Whether you’re a racer, technician, manufacturer, or educator, dyno software can help you achieve your goals.

9. Maximizing the Benefits of RC Car Dyno Software with Training

To fully leverage the capabilities of RC car dyno software, proper training is essential. Training ensures that users understand the software’s features, how to interpret data, and how to apply that knowledge to optimize their RC cars.

9.1 Understanding the Software Interface

Training helps users become familiar with the software interface, including menus, toolbars, and data displays. This ensures they can navigate the software efficiently and access the features they need.

9.2 Interpreting Data and Graphs

Training teaches users how to interpret data and graphs generated by the software. This includes understanding power and torque curves, identifying performance trends, and diagnosing issues.

9.3 Applying Knowledge to Optimize RC Cars

Training provides users with the knowledge and skills to apply the data from the software to optimize their RC cars. This includes adjusting gear ratios, tuning ESC settings, and selecting the right components for specific track conditions.

9.4 Hands-On Experience

Training often includes hands-on exercises that allow users to practice using the software and applying their knowledge to real-world scenarios. This helps reinforce their learning and build confidence.

9.5 Learning from Experts

Training is often provided by experts who have extensive experience using RC car dyno software. These experts can share their insights and tips, helping users avoid common mistakes and maximize their results.

9.6 Benefits of CAR-REMOTE-REPAIR.EDU.VN Training Programs

CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training programs designed to help users master RC car dyno software. These programs include:

- Online Courses: Self-paced courses that cover the fundamentals of RC car dyno software.

- Live Webinars: Interactive sessions with expert instructors.

- Hands-On Workshops: In-person workshops that provide hands-on experience using the software.

- Personalized Coaching: One-on-one coaching sessions with experienced technicians.

By participating in these training programs, users can gain the knowledge and skills they need to fully leverage the capabilities of RC car dyno software and optimize their RC cars for peak performance.

9.7 Gaining a Competitive Edge

Proper training in RC car dyno software can give racers a competitive edge. By understanding how to interpret data and optimize their setups, they can fine-tune their vehicles for maximum performance and gain an advantage over their competitors.

9.8 Enhancing Diagnostic Skills

Training enhances technicians’ diagnostic skills, allowing them to quickly identify and resolve issues with RC cars. This improves their efficiency and customer satisfaction.

9.9 Staying Up-to-Date

Training helps users stay up-to-date with the latest features and best practices for using RC car dyno software. This ensures they can continue to optimize their RC cars and achieve their goals.

Technician using RC car dyno software for remote diagnostics and tuning

Technician using RC car dyno software for remote diagnostics and tuning

10. Frequently Asked Questions (FAQs) About RC Car Dyno Software

Here are some frequently asked questions about RC car dyno software:

10.1 What is RC car dyno software?

RC car dyno software is a specialized application designed to measure and analyze the performance of radio-controlled (RC) vehicles.

10.2 How does RC car dyno software work?

The software interfaces with a chassis dynamometer (dyno) to capture real-time data on various parameters, such as RPM, voltage, current draw, power, and torque.

10.3 What are the benefits of using RC car dyno software?

Benefits include performance optimization, motor analysis, ESC adjustment, gear ratio calculation, and troubleshooting.

10.4 What features should I look for in RC car dyno software?

Essential features include real-time data display, data logging, graphical representation, unit conversion, and multiple runs comparison.

10.5 How do I set up RC car dyno software?

Setup involves installing the software, connecting the dyno to your computer, configuring the software settings, and calibrating the sensors.

10.6 How do I interpret dyno results?

Dyno results are typically displayed as graphs of power and torque versus RPM. Analyze peak power, peak torque, power curve, and torque curve.

10.7 Can RC car dyno software be used for remote car repair?

Yes, technicians can use dyno software to remotely diagnose and optimize RC cars by analyzing data shared by customers.

10.8 What training is available for RC car dyno software?

CAR-REMOTE-REPAIR.EDU.VN offers online courses, live webinars, hands-on workshops, and personalized coaching sessions.

10.9 How can RC car dyno software help me gain a competitive edge in racing?

By understanding how to interpret data and optimize your setups, you can fine-tune your vehicles for maximum performance.

10.10 Where can I find more information about RC car dyno software?

Visit CAR-REMOTE-REPAIR.EDU.VN for comprehensive training and resources.

Ready to take your RC car performance to the next level? Explore our comprehensive training programs and services at CAR-REMOTE-REPAIR.EDU.VN. Contact us today to learn more about how we can help you master RC car dyno software and optimize your RC car for peak performance! Address: 1700 W Irving Park Rd, Chicago, IL 60613, United States. Whatsapp: +1 (641) 206-8880.