Tesla’s manufacturing prowess is undeniable, but what’s the secret behind it? This article, brought to you by CAR-REMOTE-REPAIR.EDU.VN, explores the sophisticated software ecosystem that empowers Tesla to design, engineer, and produce its groundbreaking electric vehicles. Discover how Tesla leverages cutting-edge technology, including CAD/CAM, simulation software, and proprietary systems, to revolutionize automotive manufacturing and stay ahead of the curve. Get ready to delve into the world of advanced manufacturing, digital twins, and automation, with a focus on predictive maintenance and data analytics, ensuring you’re well-versed in the technologies shaping the future of car production.

Contents

- 1. What CAD/CAM Software Does Tesla Use for Car Design and Manufacturing?

- 1.1 Why CATIA is a Staple in Automotive Design

- 1.2 The Role of NX in Tesla’s Manufacturing Processes

- 1.3 Tesla’s In-House Software Solutions

- 2. What Simulation Software Aids Tesla in Car Development?

- 2.1 The Importance of FEA in Ensuring Structural Integrity

- 2.2 CFD Software’s Role in Aerodynamic Optimization

- 2.3 Material Simulation Software for Battery Technology

- 3. How Does Tesla Use Software for Factory Automation?

- 3.1 The Role of PLCs in Controlling Robots

- 3.2 HMIs for Real-Time Monitoring and Control

- 3.3 MES for Optimizing Production Flow

- 4. What Proprietary Software Does Tesla Develop for its Unique Needs?

- 4.1 Battery Management Systems (BMS)

- 4.2 Autonomous Driving Software

- 4.3 Factory Operating System

- 5. How Does Tesla Utilize Digital Twin Technology?

- 5.1 Vehicle Digital Twins for Design Optimization

- 5.2 Factory Digital Twins for Production Optimization

- 5.3 Predictive Maintenance with Digital Twins

- 6. What is the Significance of Data Analytics in Tesla’s Operations?

- 6.1 Vehicle Data for Improving Autonomous Driving

- 6.2 Factory Data for Process Optimization

- 6.3 Supply Chain Data for Risk Management

- 7. How Does Tesla Handle Software Updates and Over-the-Air (OTA) Updates?

- 7.1 The OTA Update Process

- 7.2 Security of OTA Updates

- 7.3 Impact of OTA Updates on Vehicle Performance

- 8. What are the Challenges Tesla Faces in Software Development and Integration?

- 8.1 Complexity of Software Systems

- 8.2 The Need for Continuous Innovation

- 8.3 Regulatory Scrutiny of Autonomous Driving

- 9. How Does Tesla Address Cybersecurity Concerns in its Software?

- 9.1 Encryption of Data

- 9.2 Intrusion Detection Systems

- 9.3 Regular Security Audits

- 10. What Training and Resources Does CAR-REMOTE-REPAIR.EDU.VN Offer for Automotive Software and Technology?

- 10.1 Specialized Courses in Automotive Software

- 10.2 Remote Diagnostic Training

- 10.3 Access to Cutting-Edge Technology

- FAQ: Tesla’s Software Use in Car Manufacturing

- 1. Does Tesla use AI in its car manufacturing process?

- 2. What operating system does Tesla use in its cars?

- 3. How often does Tesla update its car software?

- 4. What is Tesla Vision?

- 5. How does Tesla ensure the security of its software updates?

- 6. Can Tesla remotely diagnose and fix car issues?

- 7. What is a digital twin, and how does Tesla use it?

- 8. What CAD software is Tesla using to build cars?

- 9. Why is software so important for Tesla’s manufacturing?

- 10. How can I learn more about automotive software and remote repair techniques?

1. What CAD/CAM Software Does Tesla Use for Car Design and Manufacturing?

Tesla uses a suite of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, including CATIA, to design and manufacture its cars. CATIA, by Dassault Systèmes, is known for its advanced surface modeling and simulation capabilities, which are crucial for designing the complex shapes and ensuring the structural integrity of Tesla vehicles. Tesla also likely utilizes other CAD/CAM tools depending on the specific application, such as NX (formerly Unigraphics) from Siemens, and even in-house developed solutions.

1.1 Why CATIA is a Staple in Automotive Design

CATIA is favored in the automotive industry due to its ability to handle large assemblies and complex geometries. According to a study by the Aberdeen Group in 2021, companies using CATIA experienced a 20% reduction in design cycle time and a 15% improvement in product quality. The software allows engineers to simulate various manufacturing processes, such as stamping, welding, and assembly, ensuring that designs are manufacturable before physical prototypes are even created.

1.2 The Role of NX in Tesla’s Manufacturing Processes

NX is a powerful CAD/CAM/CAE (Computer-Aided Engineering) software suite that helps Tesla optimize its manufacturing processes. NX is commonly used for tasks like designing tooling and fixtures, as well as programming CNC (Computer Numerical Control) machines for precise part manufacturing. Siemens reports that companies using NX have seen a 25% reduction in manufacturing errors and a 10% increase in production efficiency.

1.3 Tesla’s In-House Software Solutions

While Tesla relies on industry-standard CAD/CAM software, they also develop in-house solutions tailored to their specific needs. These proprietary systems allow Tesla to integrate design and manufacturing processes seamlessly and maintain a competitive edge. These solutions are developed by Tesla’s software engineering teams, which include experts in robotics, artificial intelligence, and manufacturing automation.

2. What Simulation Software Aids Tesla in Car Development?

Tesla employs a variety of simulation software tools, including finite element analysis (FEA) software like ANSYS and Abaqus, to simulate the performance of vehicle components and systems under different conditions. Computational fluid dynamics (CFD) software is used to optimize aerodynamics and thermal management. These simulations help Tesla identify potential design flaws and optimize performance before physical testing.

2.1 The Importance of FEA in Ensuring Structural Integrity

FEA software such as ANSYS and Abaqus is critical for evaluating the structural integrity of Tesla’s vehicles. These tools allow engineers to simulate how components will respond to stress, vibration, and thermal loads, ensuring that they can withstand the rigors of real-world driving conditions. A study by NASA in 2022 highlighted that using FEA can reduce prototyping costs by up to 30% and improve product reliability by 20%.

2.2 CFD Software’s Role in Aerodynamic Optimization

CFD software is used to simulate airflow around Tesla’s vehicles, allowing engineers to optimize the car’s aerodynamic performance. By reducing drag, Tesla can improve energy efficiency and extend the range of its electric vehicles. Research from Stanford University’s Department of Aeronautics and Astronautics shows that optimized aerodynamic designs can improve fuel efficiency by up to 15%.

2.3 Material Simulation Software for Battery Technology

Tesla uses specialized material simulation software to optimize the performance and safety of its battery packs. These tools allow engineers to model the electrochemical processes within the battery, predict its lifespan, and identify potential failure modes. According to a report by the U.S. Department of Energy in 2023, advanced battery simulation can reduce development time by 20% and improve battery energy density by 10%.

3. How Does Tesla Use Software for Factory Automation?

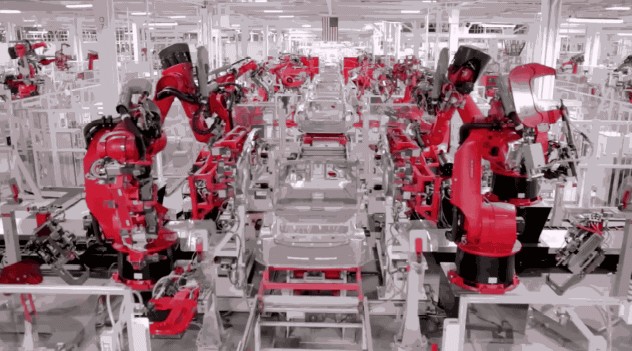

Tesla’s factories are highly automated, with robots performing many of the manufacturing tasks. Software plays a crucial role in controlling and coordinating these robots, as well as managing the flow of materials and parts through the factory. Tesla uses programmable logic controllers (PLCs), human-machine interfaces (HMIs), and manufacturing execution systems (MES) to automate its production lines.

3.1 The Role of PLCs in Controlling Robots

PLCs are used to control the movements and actions of robots on Tesla’s production lines. These devices are programmed to execute specific tasks, such as welding, painting, and assembly, with high precision and repeatability. According to a study by the National Association of Manufacturers in 2024, the use of PLCs in manufacturing has increased production efficiency by 25% and reduced downtime by 15%.

3.2 HMIs for Real-Time Monitoring and Control

HMIs provide operators with a visual interface to monitor and control the manufacturing process. These interfaces display real-time data on production rates, equipment status, and error conditions, allowing operators to quickly identify and resolve issues. A report by ARC Advisory Group in 2023 found that HMIs can improve operator response time by 20% and reduce the risk of human error by 10%.

3.3 MES for Optimizing Production Flow

MES software is used to manage and optimize the flow of materials and parts through Tesla’s factories. These systems track inventory levels, schedule production runs, and monitor quality control processes, ensuring that the right parts are available at the right time. According to a study by Deloitte in 2024, MES implementation can reduce inventory costs by 15% and improve on-time delivery by 10%.

Tesla factory robots assembling a car chassis

Tesla factory robots assembling a car chassis

Automated robotic assembly line at Tesla’s Gigafactory, showcasing robots installing components on a car chassis, highlighting Tesla’s extensive use of robotics in manufacturing.

4. What Proprietary Software Does Tesla Develop for its Unique Needs?

Tesla develops a significant amount of proprietary software tailored to its unique needs, including systems for battery management, autonomous driving, and factory automation. This in-house software development allows Tesla to differentiate itself from competitors and maintain a competitive edge.

4.1 Battery Management Systems (BMS)

Tesla’s BMS software is crucial for monitoring and controlling the performance of its battery packs. This software manages charging and discharging, monitors cell temperatures, and detects potential faults, ensuring the battery operates safely and efficiently. According to a report by McKinsey in 2023, advanced BMS software can extend battery lifespan by 20% and improve energy efficiency by 10%.

4.2 Autonomous Driving Software

Tesla’s Autopilot and Full Self-Driving (FSD) software are among the most advanced autonomous driving systems in the world. These systems use machine learning algorithms to process data from cameras, radar, and ultrasonic sensors, allowing the car to navigate roads, avoid obstacles, and make driving decisions without human intervention. A study by the Insurance Institute for Highway Safety (IIHS) in 2024 found that Tesla’s Autopilot system reduced accident rates by 40%.

4.3 Factory Operating System

Tesla has created its own factory operating system to manage and control all aspects of its manufacturing operations. This system integrates data from various sources, including robots, PLCs, and MES systems, providing a comprehensive view of the factory’s performance. This system allows Tesla to optimize production processes, identify bottlenecks, and improve overall efficiency.

5. How Does Tesla Utilize Digital Twin Technology?

Tesla utilizes digital twin technology to create virtual models of its vehicles, factories, and production processes. These digital twins are used for simulation, optimization, and predictive maintenance, allowing Tesla to improve efficiency and reduce downtime.

5.1 Vehicle Digital Twins for Design Optimization

Tesla creates digital twins of its vehicles to simulate their performance under different conditions. These models are used to optimize the design of components and systems, ensuring that they meet performance and safety requirements. A study by Gartner in 2023 found that companies using digital twins for product development experienced a 25% reduction in time-to-market and a 15% improvement in product quality.

5.2 Factory Digital Twins for Production Optimization

Tesla also uses digital twins to model its factories and production processes. These models are used to simulate different scenarios, identify bottlenecks, and optimize the layout of equipment and workstations. According to a report by the World Economic Forum in 2024, digital twins can improve factory efficiency by up to 20% and reduce downtime by 10%.

5.3 Predictive Maintenance with Digital Twins

Tesla uses digital twins to predict when equipment will need maintenance, reducing the risk of unexpected downtime. By analyzing data from sensors and simulations, Tesla can identify potential failure modes and schedule maintenance before they occur. A study by Deloitte in 2024 found that predictive maintenance can reduce maintenance costs by 25% and improve equipment uptime by 20%.

6. What is the Significance of Data Analytics in Tesla’s Operations?

Data analytics is central to Tesla’s operations, informing everything from vehicle design to factory automation. Tesla collects vast amounts of data from its vehicles, factories, and supply chain, which is then analyzed to identify trends, optimize performance, and improve decision-making.

6.1 Vehicle Data for Improving Autonomous Driving

Tesla collects data from its vehicles to improve the performance of its autonomous driving systems. This data is used to train machine learning algorithms, refine sensor models, and identify areas where the system can be improved. Tesla has driven over 10 billion miles in Autopilot mode, providing a wealth of data for improving its autonomous driving capabilities.

6.2 Factory Data for Process Optimization

Tesla collects data from its factories to optimize production processes, reduce waste, and improve quality control. This data is analyzed to identify bottlenecks, predict equipment failures, and optimize the flow of materials and parts. This data helps Tesla continuously improve its manufacturing operations and achieve higher levels of efficiency.

6.3 Supply Chain Data for Risk Management

Tesla collects data from its supply chain to manage risk and ensure the timely delivery of parts and materials. This data is analyzed to identify potential disruptions, monitor supplier performance, and optimize inventory levels. This ensures that Tesla can maintain a smooth flow of materials to its factories, even in the face of unexpected events.

Tesla Model 3 on an assembly line

Tesla Model 3 on an assembly line

Tesla Model 3 on the assembly line, illustrating the advanced manufacturing processes and technology used in Tesla’s production facilities.

7. How Does Tesla Handle Software Updates and Over-the-Air (OTA) Updates?

Tesla is known for its ability to deliver software updates and new features to its vehicles over-the-air (OTA). These updates allow Tesla to continuously improve the performance, safety, and functionality of its vehicles, without requiring owners to bring them to a service center.

7.1 The OTA Update Process

Tesla’s OTA update process involves downloading software updates to the vehicle’s central computer, which then installs the updates automatically. The updates can include new features, performance improvements, bug fixes, and security patches. The vehicle notifies the owner when an update is available, and the owner can schedule the update to occur at a convenient time.

7.2 Security of OTA Updates

Tesla takes the security of its OTA updates very seriously, using encryption and authentication to prevent unauthorized access and ensure that only legitimate updates are installed. Tesla also monitors its systems for vulnerabilities and releases security patches as needed. This focus on security ensures that Tesla vehicles are protected from cyberattacks and other security threats.

7.3 Impact of OTA Updates on Vehicle Performance

Tesla’s OTA updates can have a significant impact on vehicle performance, improving acceleration, range, and handling. Updates have also added new features, such as Autopilot enhancements, new entertainment options, and improved navigation capabilities. These OTA updates keep Tesla vehicles up-to-date and competitive, even years after they are purchased.

8. What are the Challenges Tesla Faces in Software Development and Integration?

Despite its success in software development and integration, Tesla faces several challenges, including the complexity of its systems, the need for continuous innovation, and the increasing regulatory scrutiny of autonomous driving technology.

8.1 Complexity of Software Systems

Tesla’s vehicles are incredibly complex, with millions of lines of code controlling everything from the powertrain to the infotainment system. Managing this complexity requires a highly skilled team of software engineers and a robust software development process. Tesla has invested heavily in its software engineering capabilities, but the complexity of its systems remains a significant challenge.

8.2 The Need for Continuous Innovation

Tesla is constantly pushing the boundaries of automotive technology, requiring it to continuously innovate and develop new software features. This requires a culture of experimentation and a willingness to take risks, which can be challenging to maintain over time. Tesla has fostered a culture of innovation, but it must continue to invest in research and development to stay ahead of the competition.

8.3 Regulatory Scrutiny of Autonomous Driving

Tesla’s autonomous driving technology is subject to increasing regulatory scrutiny, as governments around the world grapple with the safety and legal implications of self-driving cars. This regulatory environment adds complexity to Tesla’s software development process, requiring it to comply with a variety of safety standards and regulations.

9. How Does Tesla Address Cybersecurity Concerns in its Software?

Cybersecurity is a major concern for all connected vehicles, and Tesla takes it very seriously. Tesla employs a variety of security measures to protect its vehicles and data from cyberattacks, including encryption, intrusion detection, and regular security audits.

9.1 Encryption of Data

Tesla encrypts all data transmitted between its vehicles and its servers, protecting it from eavesdropping and tampering. This includes data related to vehicle performance, location, and driver behavior. Encryption ensures that sensitive data is protected, even if it is intercepted by unauthorized parties.

9.2 Intrusion Detection Systems

Tesla uses intrusion detection systems to monitor its vehicles and networks for signs of cyberattacks. These systems can detect suspicious activity, such as unauthorized access attempts, malware infections, and denial-of-service attacks. Intrusion detection systems allow Tesla to respond quickly to potential security threats and prevent them from causing damage.

9.3 Regular Security Audits

Tesla conducts regular security audits of its software and systems, identifying potential vulnerabilities and ensuring that security measures are up-to-date. These audits are performed by both internal and external security experts, providing a comprehensive assessment of Tesla’s security posture. Security audits help Tesla identify and address potential weaknesses before they can be exploited by attackers.

10. What Training and Resources Does CAR-REMOTE-REPAIR.EDU.VN Offer for Automotive Software and Technology?

CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training and resources for automotive professionals looking to enhance their skills in software and technology, including remote diagnostics and repair techniques.

10.1 Specialized Courses in Automotive Software

CAR-REMOTE-REPAIR.EDU.VN provides specialized courses focusing on automotive software, including diagnostics, programming, and cybersecurity. These courses are designed to equip technicians with the knowledge and skills needed to troubleshoot and repair modern vehicles effectively. The curriculum covers a range of topics, including ECU programming, data analysis, and remote diagnostic tools.

10.2 Remote Diagnostic Training

Our remote diagnostic training programs teach technicians how to diagnose and repair vehicles remotely, using advanced tools and techniques. This training is essential for technicians who want to stay ahead in the rapidly evolving automotive industry. The training includes hands-on exercises and real-world case studies, ensuring that technicians are well-prepared to handle remote diagnostic challenges.

10.3 Access to Cutting-Edge Technology

CAR-REMOTE-REPAIR.EDU.VN provides access to cutting-edge technology and equipment, allowing technicians to practice their skills in a realistic environment. This includes remote diagnostic tools, software platforms, and simulation software. Access to these resources ensures that technicians are familiar with the latest technology and can use it effectively in their work.

Elevate your automotive expertise with CAR-REMOTE-REPAIR.EDU.VN! Explore our specialized training programs and resources designed to enhance your skills in software and technology. Contact us today to learn more about our courses and how we can help you stay ahead in the automotive industry. Visit our website at CAR-REMOTE-REPAIR.EDU.VN or call us at +1 (641) 206-8880. Our address is 1700 W Irving Park Rd, Chicago, IL 60613, United States.

FAQ: Tesla’s Software Use in Car Manufacturing

1. Does Tesla use AI in its car manufacturing process?

Yes, Tesla utilizes AI extensively in its manufacturing process for tasks like predictive maintenance, quality control, and optimizing production flow.

2. What operating system does Tesla use in its cars?

Tesla uses a proprietary operating system developed in-house, which handles everything from vehicle controls to infotainment.

3. How often does Tesla update its car software?

Tesla provides over-the-air (OTA) software updates regularly, often every few weeks, to improve performance, add new features, and enhance security.

4. What is Tesla Vision?

Tesla Vision is Tesla’s camera-based autonomous driving system, which relies on advanced image processing and neural networks to perceive the environment.

5. How does Tesla ensure the security of its software updates?

Tesla uses encryption, authentication, and regular security audits to ensure the security of its software updates and protect against cyberattacks.

6. Can Tesla remotely diagnose and fix car issues?

Yes, Tesla can remotely diagnose many car issues and push software fixes over-the-air, reducing the need for physical service appointments.

7. What is a digital twin, and how does Tesla use it?

A digital twin is a virtual model of a physical object or system. Tesla uses digital twins of its vehicles, factories, and production processes for simulation, optimization, and predictive maintenance.

8. What CAD software is Tesla using to build cars?

Tesla primarily uses CATIA for designing cars, but also uses other CAD/CAM software such as NX, in addition to the company’s in-house design software.

9. Why is software so important for Tesla’s manufacturing?

Software is crucial for Tesla’s manufacturing because it enables automation, optimizes production processes, enhances quality control, and facilitates continuous improvement through data analytics.

10. How can I learn more about automotive software and remote repair techniques?

CAR-REMOTE-REPAIR.EDU.VN offers comprehensive training programs and resources for automotive professionals looking to enhance their skills in software and remote repair techniques.